Gas phase permeation precipitation method for preparation of supported nanometer nickel hydrogenation catalyst

A nano-nickel hydrogenation catalyst and gas-phase infiltration technology, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of low catalytic efficiency, low nickel content of the catalyst, sintering deactivation of nano-crystal grains, etc. Achieve the effects of simple process, easy control of conditions and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 5L nickel carbonyl liquid from the storage tank into the evaporator, weigh 800g gamma alumina strip carrier (φ1mm) and put it into the vapor phase infiltration / deposition tower, and then operate according to the above steps 2-6. The operating parameters are: the temperature of the evaporator water bath is 35°C; the volume mixing ratio of nickel carbonyl vapor and carrier gas is 1:6, and the carrier gas is 99.9% nitrogen; during gas phase infiltration, the temperature of the material tower is 40°C, and the time is 0.5 h; during pyrolysis deposition, the temperature of the material tower is 90°C, and the time is 0.5h; after the deposition, the baking temperature is controlled at 330°C, and the time is 1h.

[0026] After the experiment, the nickel content of the catalyst was analyzed to be 5.6 wt%, and the size of the nano-nickel was analyzed by a field emission scanning electron microscope to be 25-45nm.

Embodiment 2-5

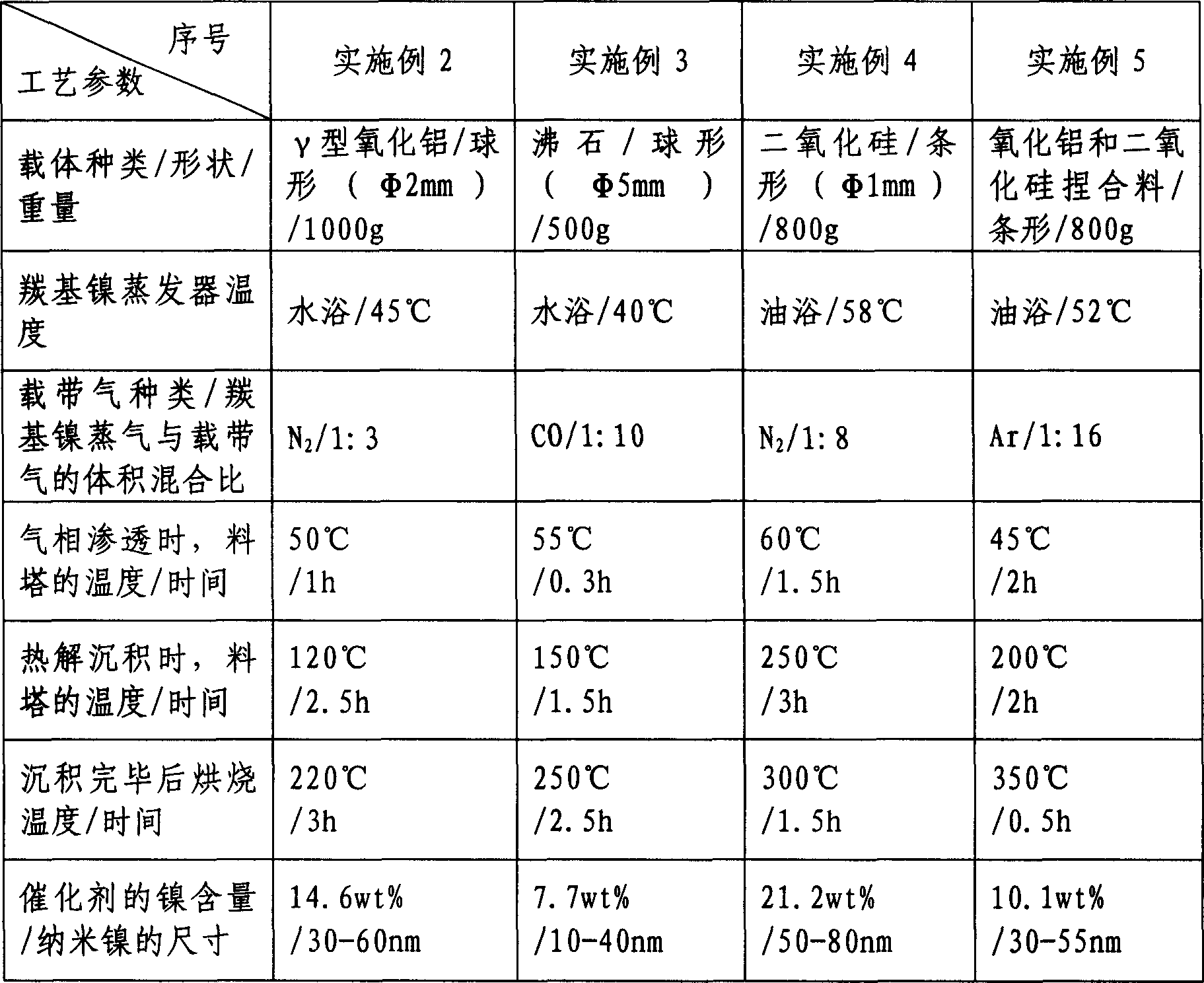

[0027] Embodiment 2-5, experiment method is the same as embodiment 1, and experiment parameter is shown in Table 1.

[0028] Table 1

[0029]

Embodiment 6

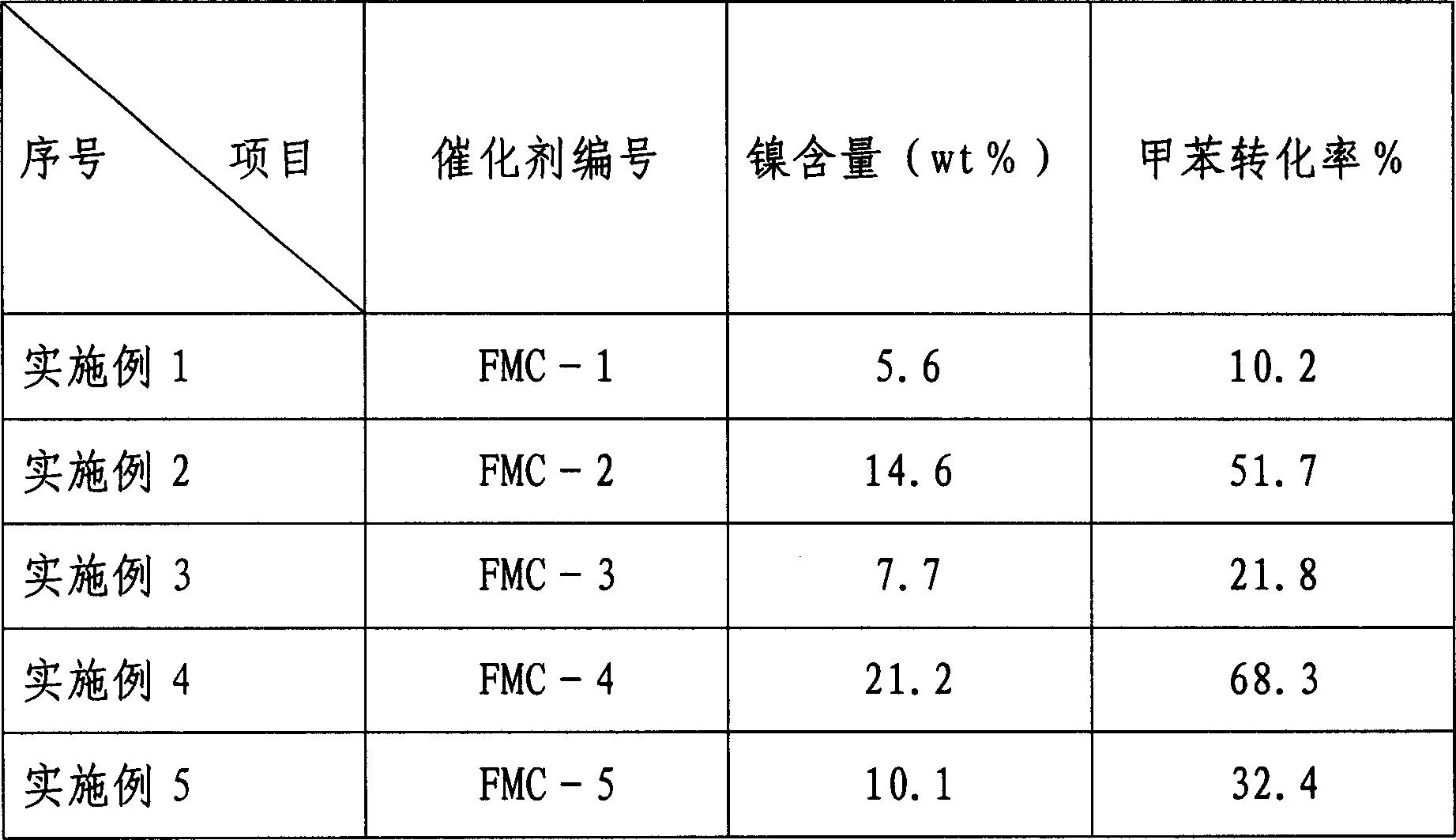

[0031] Catalyst hydrogenation performance evaluation by continuous micro-reflector-chromatography system. The hydrogenated oil sample is a mixture of decahydronaphthalene (60%) and toluene (40%), and the catalyst consumption is 0.1 g. The catalyst was reduced at 200°C for 3h before hydrogenation. The hydrogenation reaction was carried out under normal pressure, the hydrogen flow rate was 180ml / min, the hydrogen-to-oil ratio was 1800:1, the hydrogenation temperature was 130°C, and the chromatographic sampling and analysis were carried out after 3 hours of passing the oil sample. The hydrogenation evaluation results of the catalysts of Examples 1-5 are shown in Table 2.

[0032] Toluene conversion % = (toluene content in oil sample before hydrogenation - toluene content in oil sample after hydrogenation) / toluene content in oil sample before hydrogenation × 100%

[0033] Table 2

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com