Apparatus for marking a defect

A defect marking and marking technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of product quality reduction, fracture, strength reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

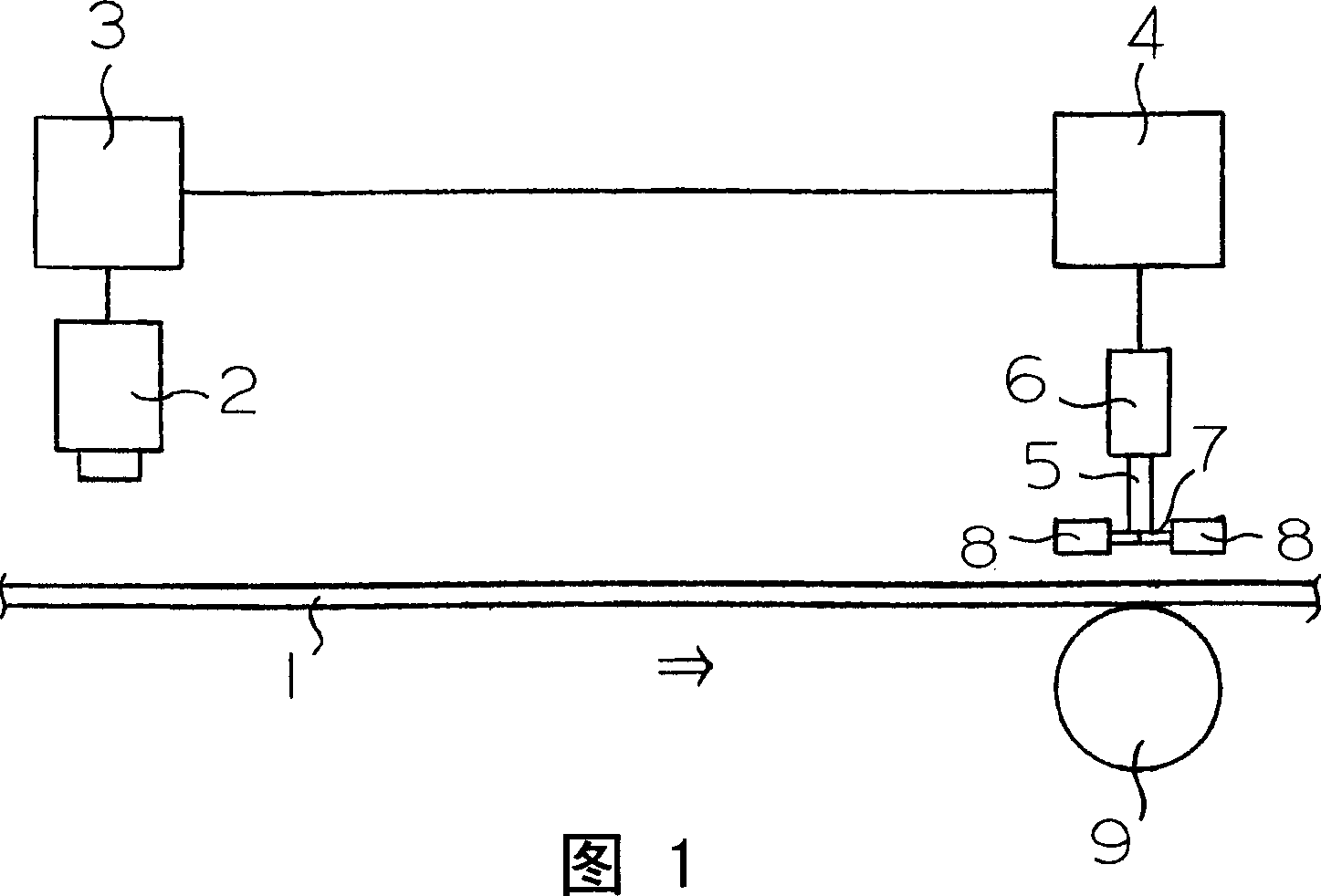

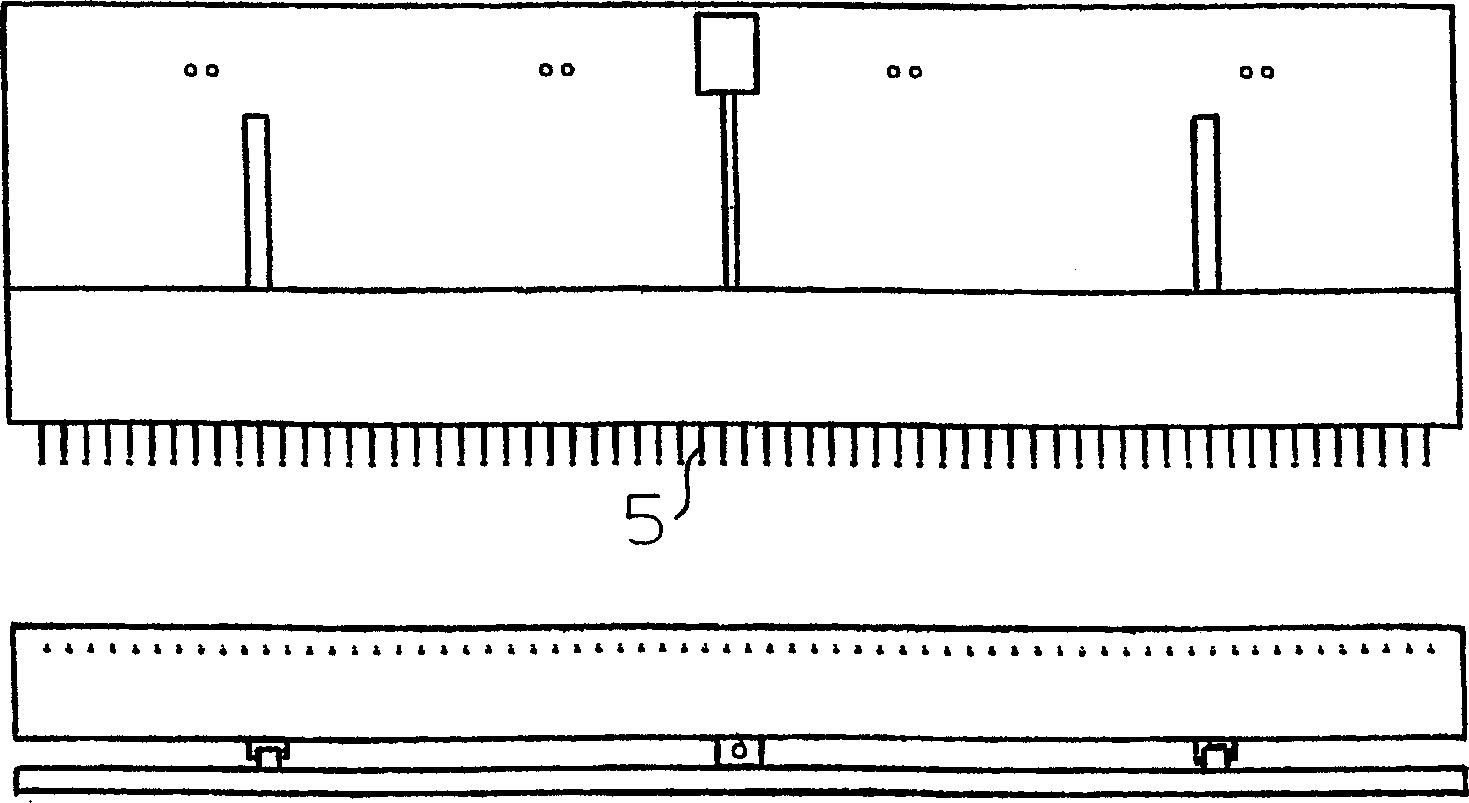

[0165] The inspection was carried out on a biaxially stretched polyethylene terephthalate film having a width of 1600 mm and a thickness of 50 μm. Above the polyethylene terephthalate film, 8 CCD cameras were installed at a pitch of 200 mm, and below the polyethylene terephthalate film, light sources were installed at positions corresponding to the CCD cameras. Above the polyethylene terephthalate film downstream of the CCD camera and the light source 2.0m, a marking head is arranged, and the marking head has 64 groups within a width of 1600mm according to a 25mm pitch, and the marking head will The receiving tube of the oil-based marking pen operated by the solenoid is combined with the shutter of the receiving tube operated by the air cylinder, and a support is provided at the position facing the marking head under the polyethylene terephthalate film. roll.

[0166] The solvent of the ink of oily marking pen is the mixed solvent of the ethanol of 70% by weight and the propy...

Embodiment 2

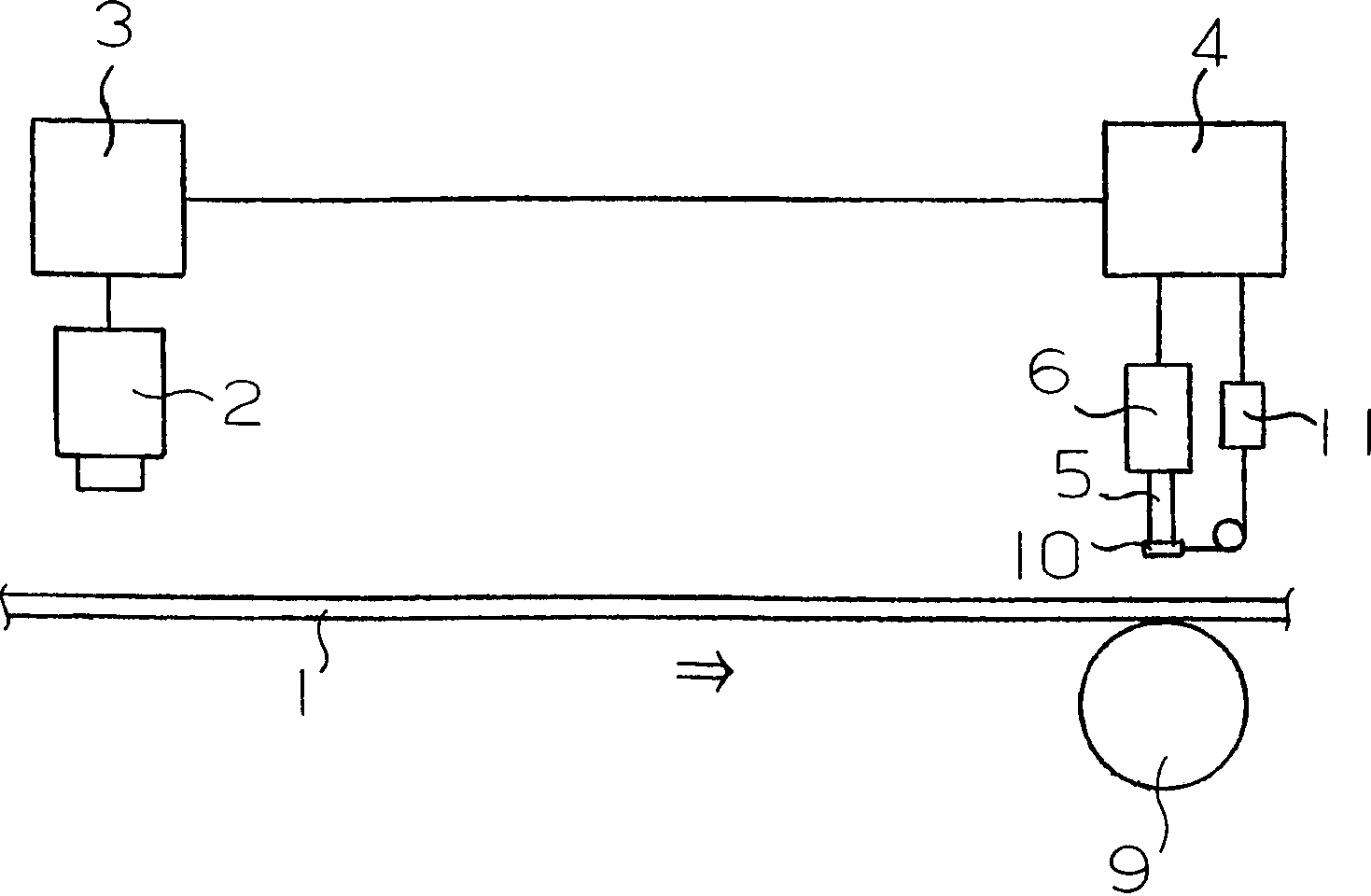

[0169] Inspection was performed on a biaxially stretched polyethylene terephthalate film having a width of 1400 mm and a thickness of 100 μm. Seven CCD cameras were installed at a pitch of 200 mm above the polyethylene terephthalate film, and a light source was installed at a position facing the CCD cameras below the polyethylene terephthalate film. Above the polyethylene terephthalate film downstream of the CCD camera and the light source 2.0m, a marking head is arranged, and the marking head has 70 groups within a width of 1400mm according to a 20mm pitch, and the marking head will The receiving tube of the oil-based marker pen operated by the solenoid is combined with the shutter of the receiving tube operated by the solenoid, under the polyethylene terephthalate film, at the position facing the marking head Set up backup rolls.

[0170] The ink solvent of the oil-based marker pen is ethanol, and the pen tip is made of fiber, and has a cylindrical shape with a diameter of ...

Embodiment B1

[0174]A polycarbonate roll film of a tape carrier for electronic device mounting with a width of 1200 mm and a thickness of 0.2 mm was cut into 60 product films with a width of 20 mm. Six CCD cameras were installed at a pitch of 200 mm above the film, and a light source was installed at a position facing the CCD cameras below the film. A marking device is installed above the film downstream of the CCD camera and the light source 2.0m down. The marking device has 60 groups within a width of 1200mm at a pitch of 20mm. The marking device is an oily marker operated by a solenoid. The assembly of the receiving tube of the pen and the shutter of the receiving tube operated by the air cylinder is provided below the film, on the upstream side of 5 mm from the marking device, and a support roller in contact with the film is provided. An inspection device that processes images taken by a CCD camera to detect defects is connected to a drive device that opens the shutter of an oil marker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com