Ferrimagnetism fluid

A magnetic fluid and magnetic ferrite technology, applied in the direction of magnetic liquid, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of uneven particle size, loss, magnetic condensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of Magnetic Ferrite Particles

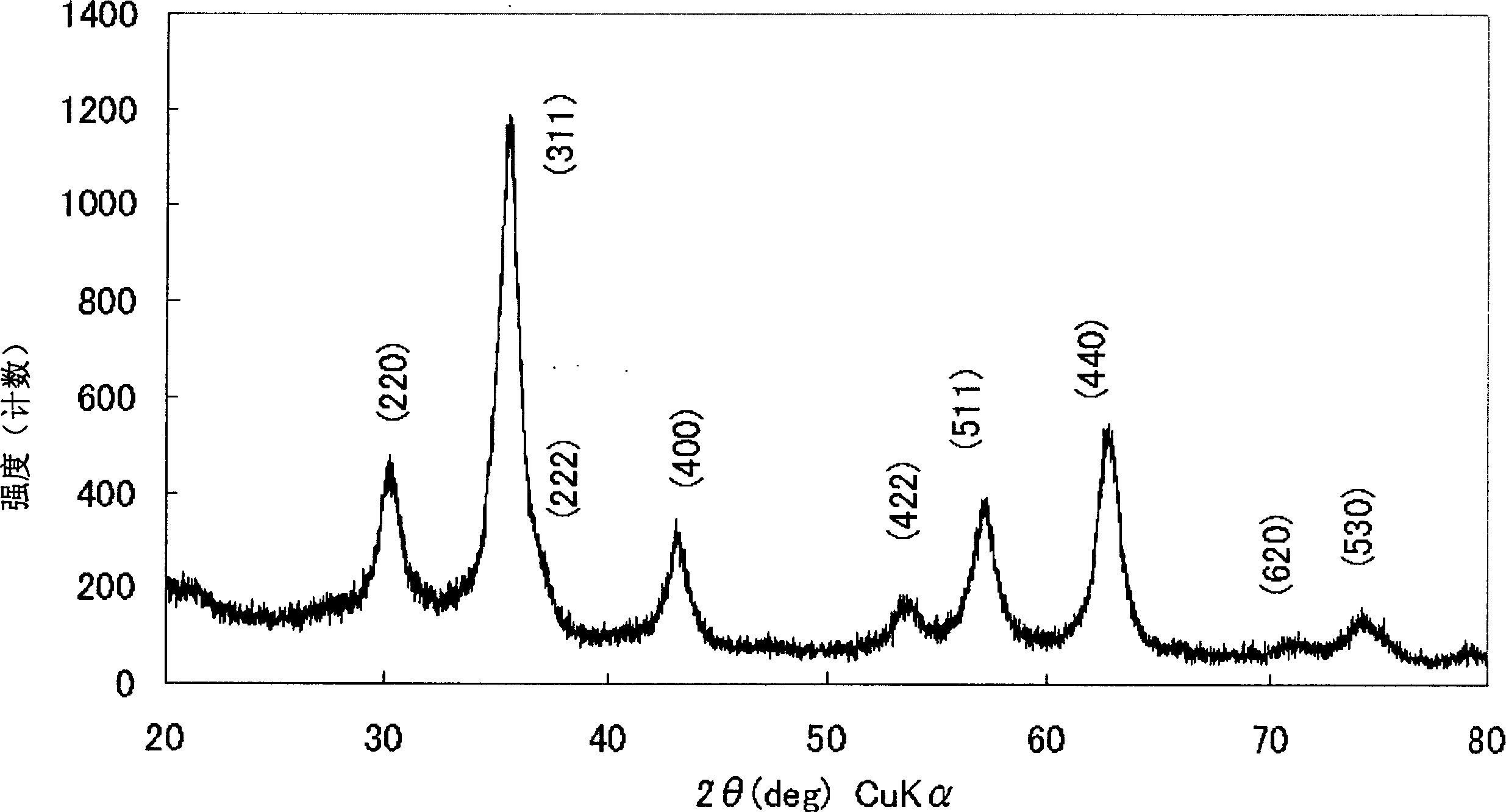

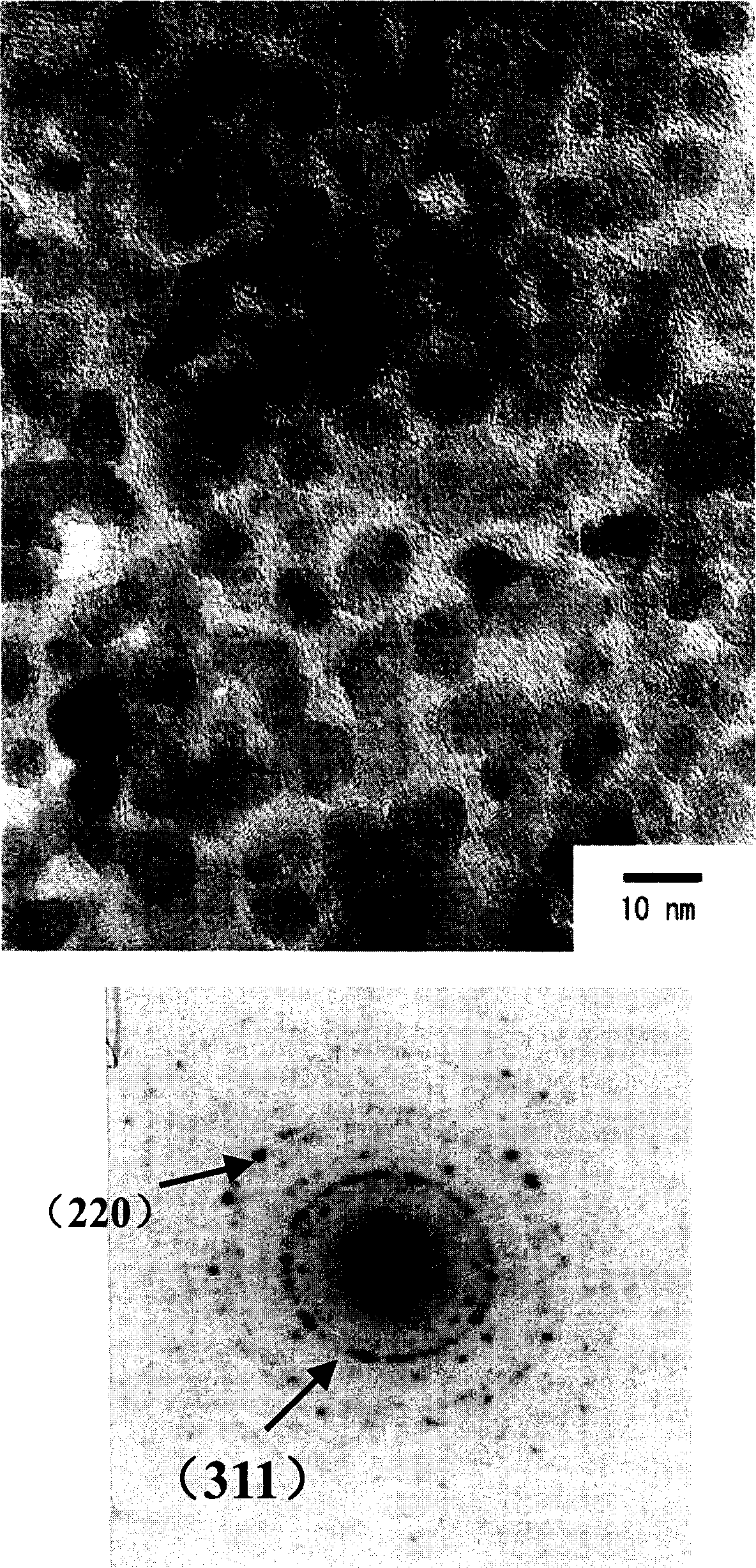

[0055] Prepare 150 ml of a mixed solution of 0.125 mol / l ferrous chloride reagent and 0.25 mol / l ferric chloride reagent, and prepare an appropriate amount of 1 mol / l NaOH solution in addition. Add the deionized water of 100ml in the 500ml beaker, drip mixed solution and sodium hydroxide solution simultaneously with the speed of 5ml / min, can control the particle size of magnetic ferrite particle by the pH value of control solution, utilize transmission electron microscope ( TEM), powder refraction X-ray (XRD) and the use of vibratory magnetic susceptibility measuring device (VSM) to evaluate it, as shown in Table 1. The Curie temperature of the synthesized magnetic nano-powder at pH 7 was determined to be 472° C. by using a high-temperature magnetic measuring device.

[0056] PH value

3

5

6

7

9

11

Particle size (nm)

3.2

4.8

6.1

7.9

11.7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com