Evaporative cooling traction transformer

A traction transformer and evaporative cooling technology, applied in the field of transformers, can solve the problems of heavy weight, poor environmental protection, poor fire resistance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

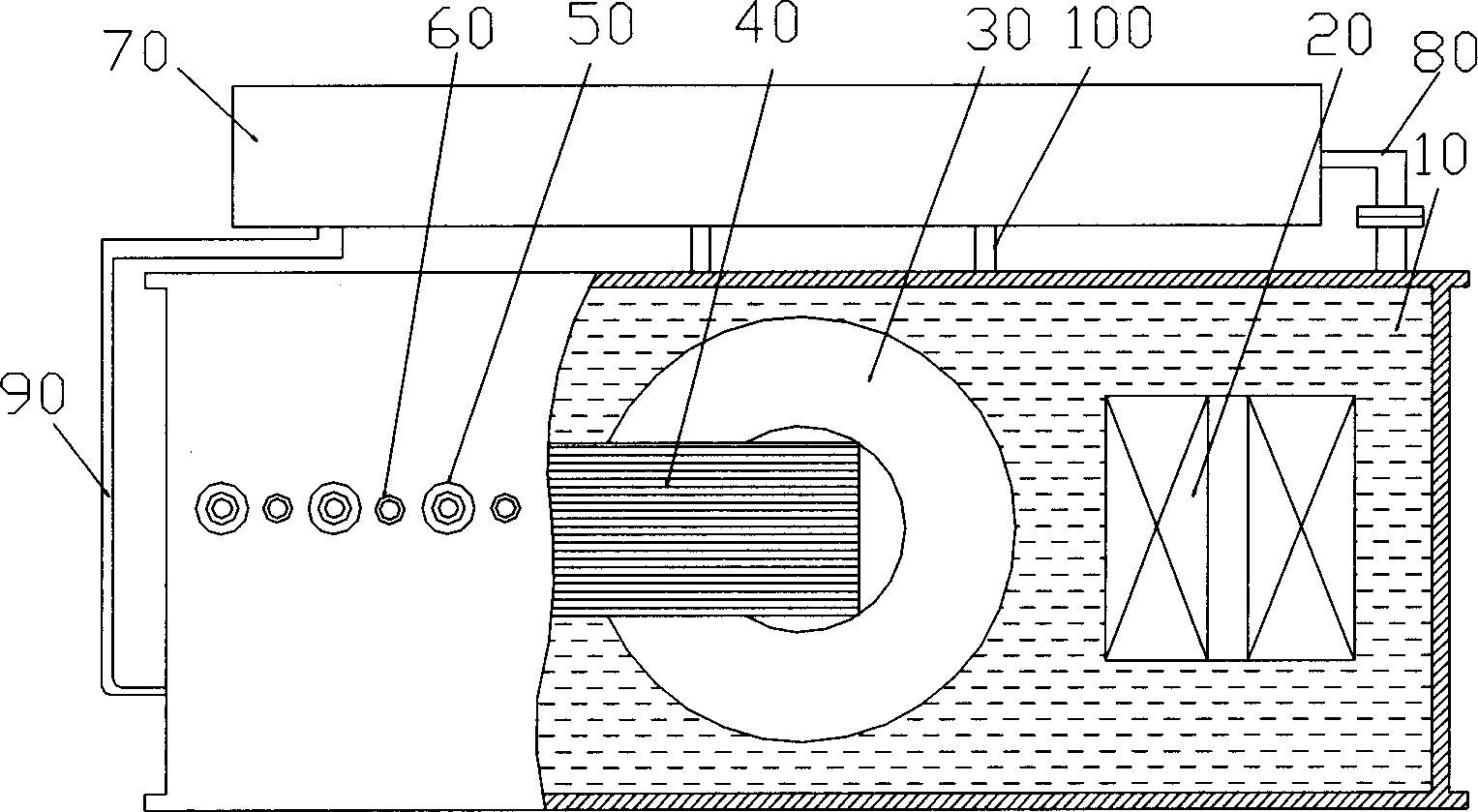

[0028] One of the specific embodiments of the present invention, the structure of the evaporative cooling traction transformer using a vertical condenser, a core-type body, and a core-type air-core reactor is as follows figure 1 As shown, the transformer adopts a core-type body, and the oil tank 10 is filled with evaporative cooling medium, and its structure is the same as that of a conventional high-voltage oil-immersed power transformer. The winding 30 and the iron core 40 are soaked in the evaporative cooling medium of the transformer. The side of the transformer oil tank 10 is connected with the high voltage bushing 50 and the low voltage bushing 60 . The upper end of the gas collecting pipe 80 is connected with the cooling space of the condenser 70, the lower end of the gas collecting pipe 80 is connected with the transformer oil tank, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com