Emulsified fcc feetstock for improved spray atomization

A technology of atomization efficiency and raw material composition, which is applied in the direction of catalytic cracking, cracking, fuel, etc., and can solve the problem of gas solubility reduction and other problems

Inactive Publication Date: 2006-06-28

GENERAL ELECTRIC CO

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As the pressure drops very rapidly in a pressure-type nebulizer, the solubility of this gas also decreases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042] Determining the effectiveness of surfactants to stabilize water-in-oil emulsions

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

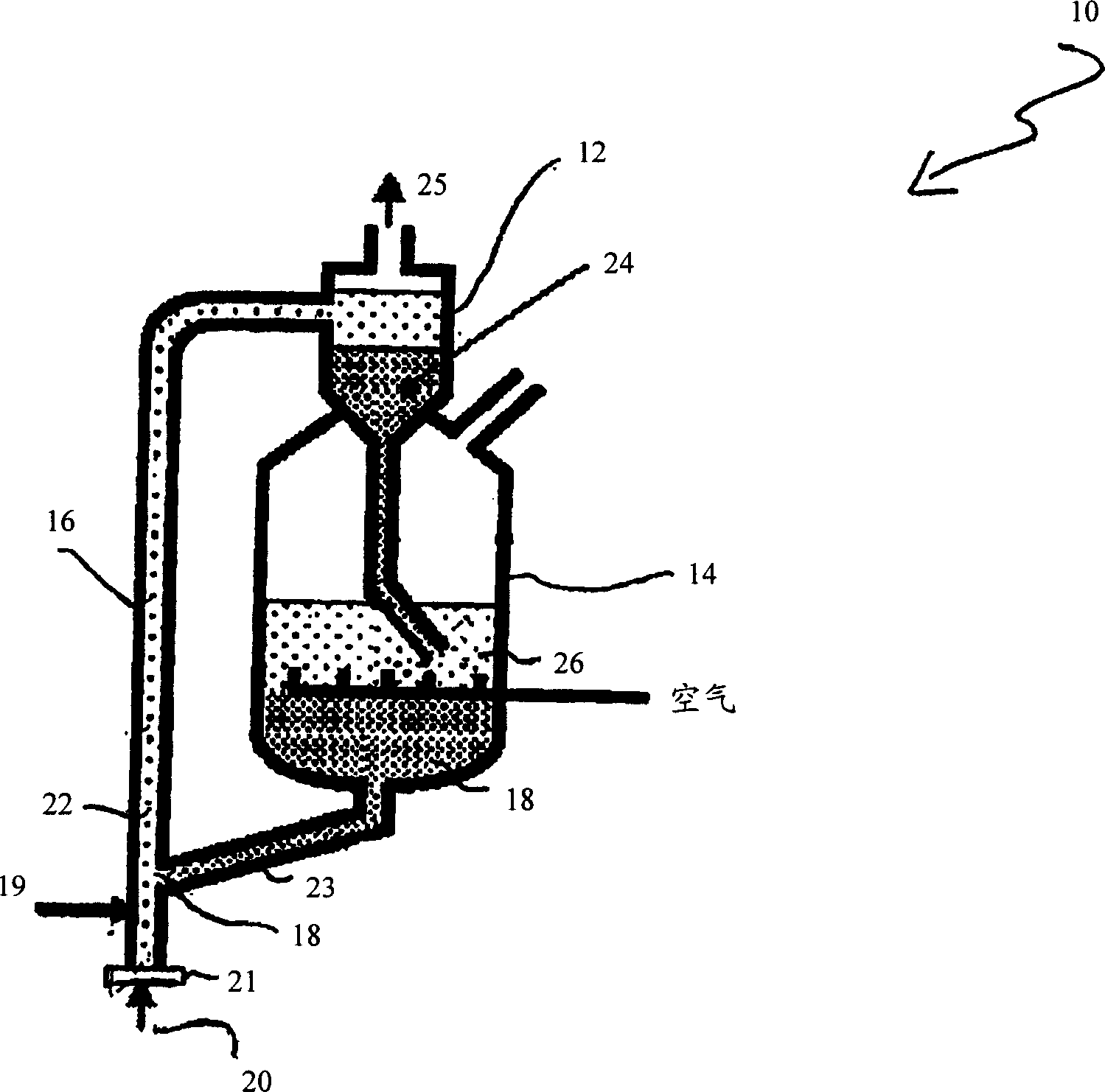

The present invention provides a feedstock composition for increasing atomization efficiency in hydrocarbon processing comprising a hydrocarbon water-in-oil emulsion containing a non-hydrocarbon oil capable of stabilizing the emulsion and having a hydrophilic-lipophilic balance greater than about 12. Ionic surfactant. The emulsion comprises water droplets having a diameter of about 5-10 microns substantially uniformly dispersed in the hydrocarbon oil phase. These surfactants are capable of stabilizing hydrocarbon water-in-oil emulsions under the temperature and pressure conditions associated with hydrocarbon processing, and the feedstock composition of the present invention provides metastable water-in-oil emulsions in which expanding water vapor is released in a spray state at system pressure The explosion destroys the large oil droplets and produces small oil droplets.

Description

field of invention [0001] The present application relates to a hydrocarbon feedstock composition suitable for processing in a pressure-type atomizer. In particular, the present invention relates to a feedstock composition for improved atomization in hydrocarbon processing comprising an emulsified hydrocarbon water-in-oil emulsion. Background of the invention [0002] Catalytic cracking includes gas oil processing using catalysts to crack carbon-carbon bonds, especially catalytic cracking includes breaking saturated C12+ molecules into C2-C4 olefins and paraffins, gasoline, light oil, and coke. Cracking can be used to reduce the average molecular weight and produce higher yields of fuel products. Most reactions are endothermic and heat must be provided for the cracking process. Cracking can be purely thermal or thermal and catalytic. In general, it is desirable to promote catalytic cracking over thermal cracking due to the unwanted by-products produced by thermal cracking....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G11/18C10L1/32

CPCC10L1/328C10G11/18C10L1/32

Inventor 威利·L·帕克柯林·W·克罗斯艾伦·E·戈里亚斯泽夫斯基

Owner GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com