Special icehouse for hydropower engineering

A special technology for hydropower projects, which is applied in the field of special ice storage for hydropower projects, can solve the problems that the overall rigidity is not easy to be guaranteed, it is not easy to carry and demolish the second time, and the workload of on-site welding is large, so as to achieve easy ice transportation speed and disassembly work. The effect of large quantity and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

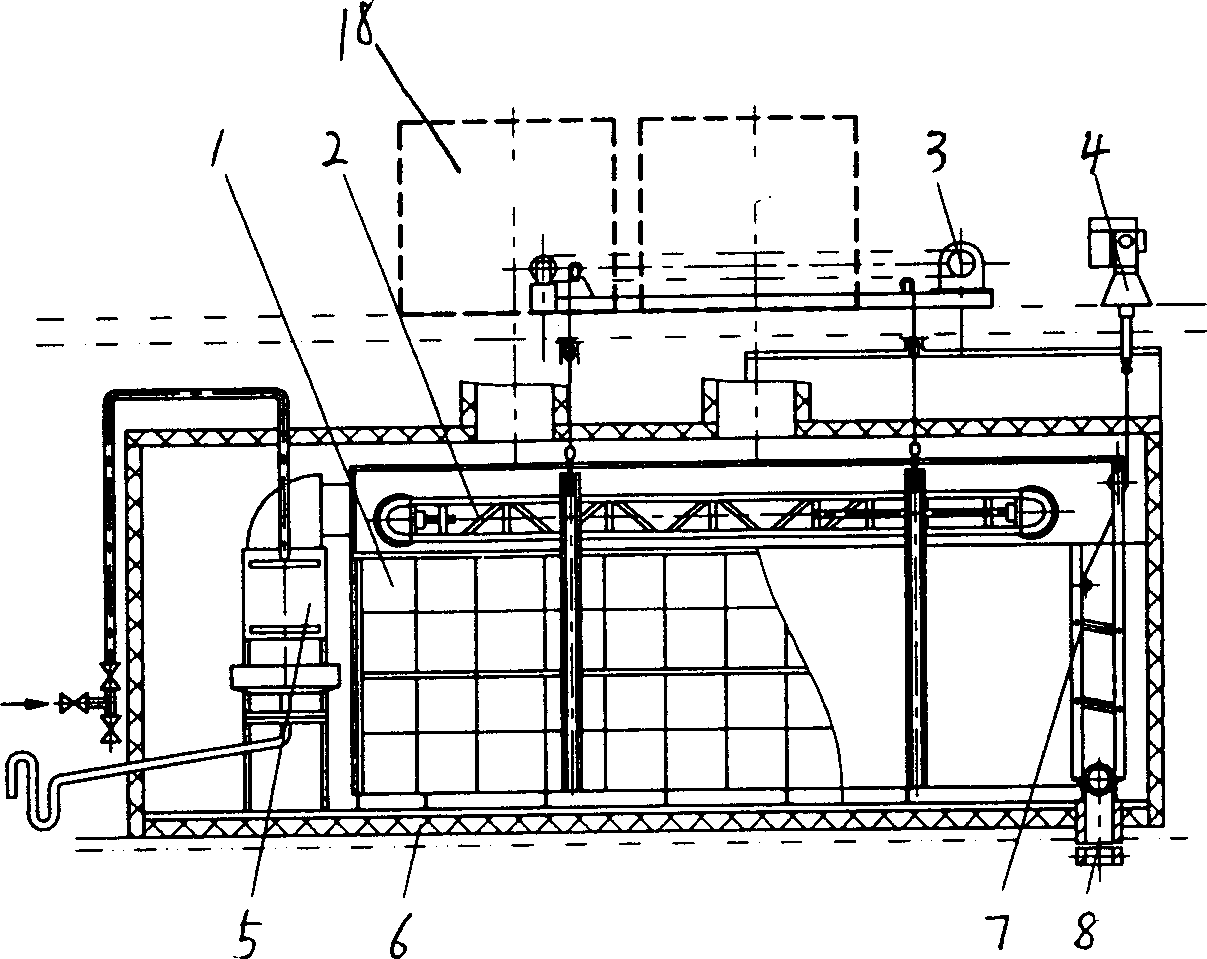

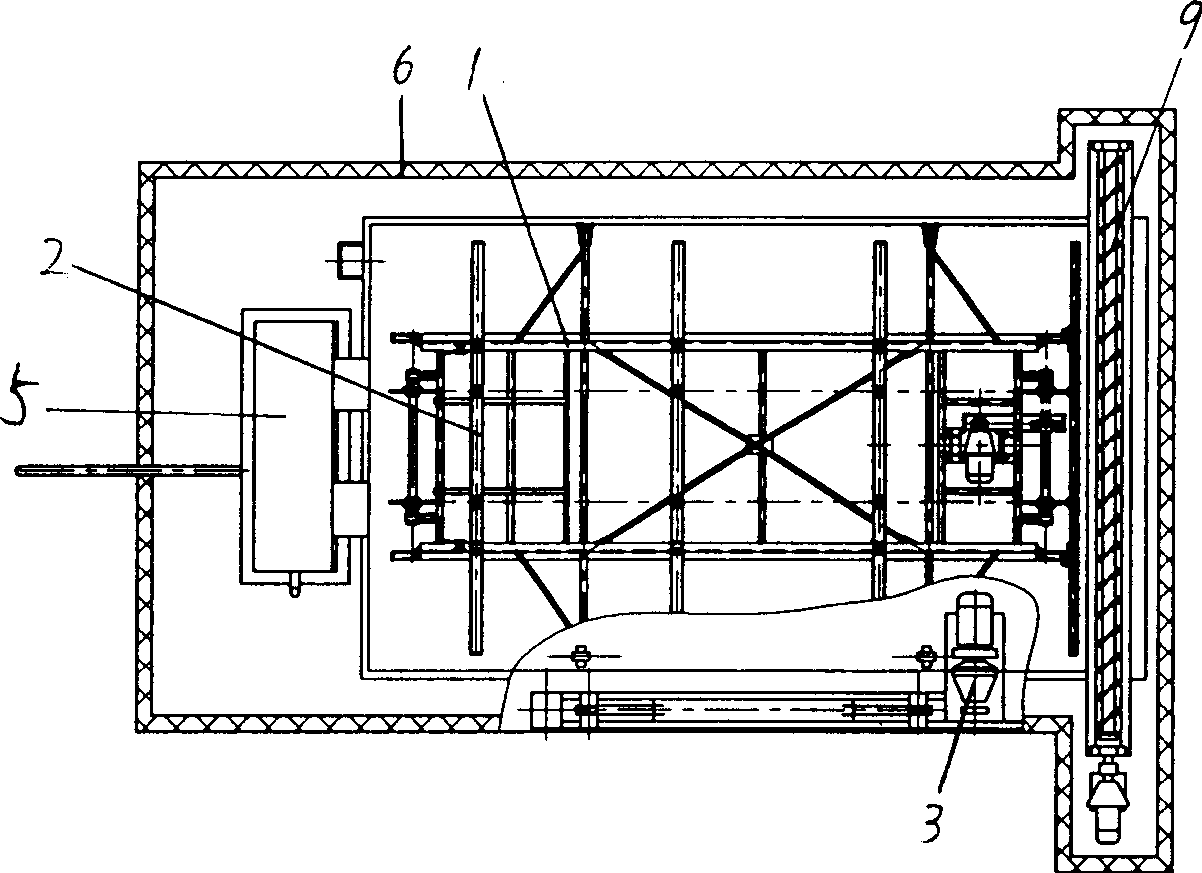

[0021] Such as Figure 1 to 3 As shown, this embodiment consists of ice storage 1, ice rake 2, flake ice machine 18, ice rake hoisting device 3, ice door hoisting device 4, air cooler 5 heat insulation structure 6, ice door 7, ice outlet gate 8 and the ice out screw machine 9, in which the ice storage 1 is arranged under the flake ice machine 18, the ice rake 2 is arranged in the ice storage 1, and the ice rake hoisting device 3 is arranged above the ice rake 2, An air cooler 5 is installed on one side of the ice storage 1, and an ice door 7 and an ice outlet gate 8 are installed on the other side. The ice outlet screw 9 is installed above the ice outlet gate 8 and an ice door is installed above the ice door 7 The lifting device 4 is provided with a heat insulation structure 6 on the outside of the ice storage 1, the ice rake machine 2, the air cooler 5, the ice door 7, the ice outlet gate 8 and the ice outlet screw 9.

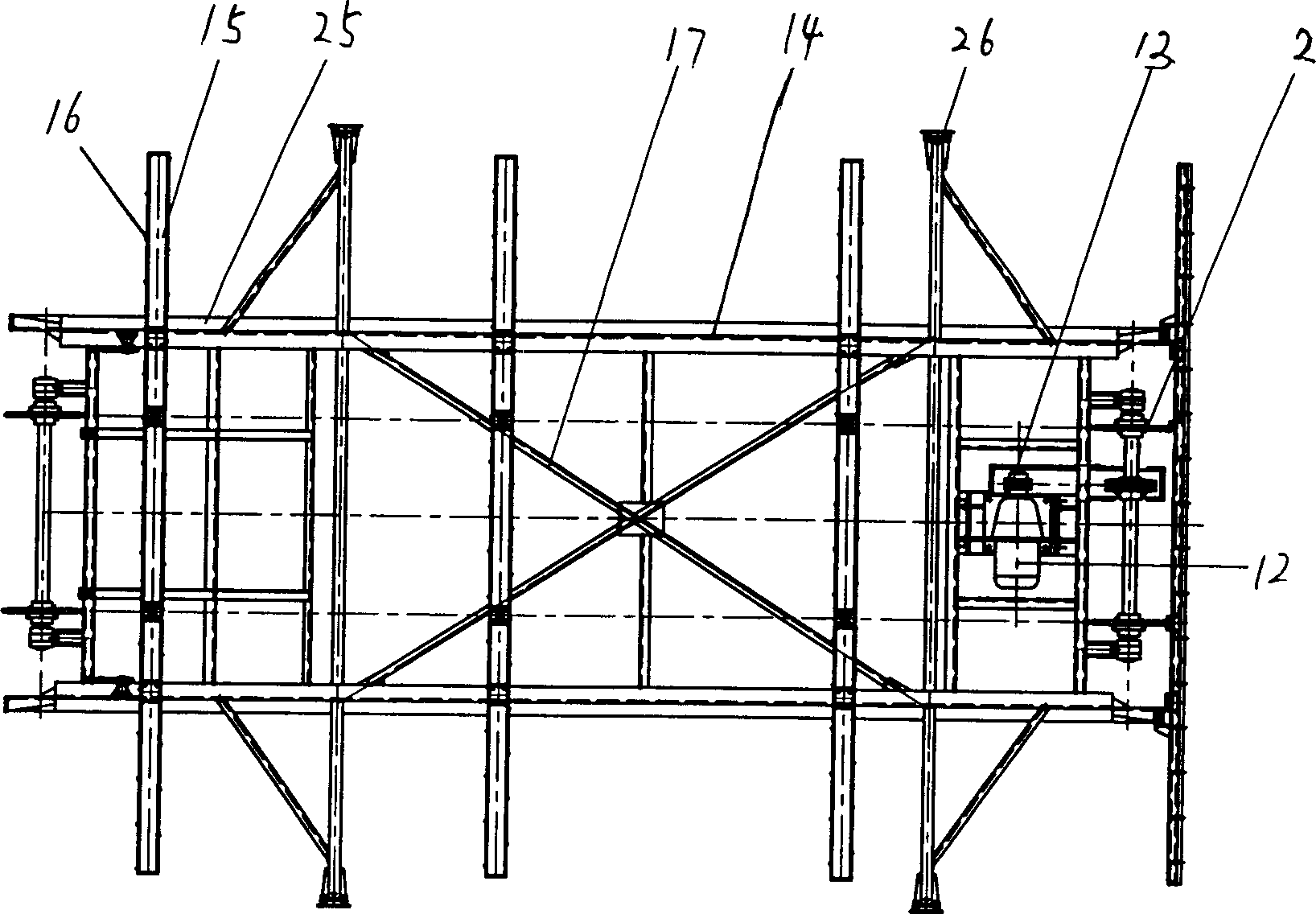

[0022] Such as Figure 4 to 7 As shown, the ice storage 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com