Polymer material possessing thiol removal action

A technology of polymer material and sweetening of mercaptans, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as complex processes, non-contamination, and waste lye pollution, and achieves wide applicability, convenient use, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. the structure of the polymer material with sweetening effect described in the embodiment:

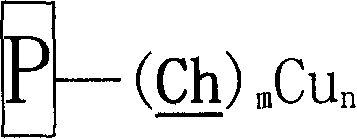

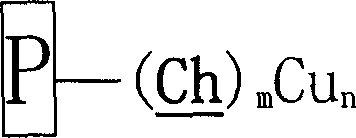

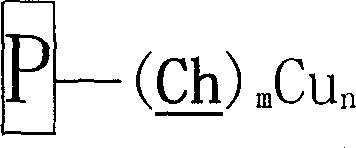

[0019] The polymer material with the effect of removing thiol described in the embodiments of the present invention is a chelating polymer combined with divalent copper ions, which is obtained by the reaction of the corresponding chelating polymer and divalent copper salt. Its structure It is characterized in that the polymer material contains positive divalent copper ions, and the copper ions are connected to the polymer skeleton through a chelating group. The structure of the polymer material is expressed as:

[0020]

[0021] In the above formula is a chelating polymer, where represents the polymer backbone, Ch Indicates a chelating group for binding to copper ions.

[0022] The backbone of the polymer material Including polystyrene, phenolic resin, polypropylene, polyacrylonitrile, cellulose.

[0023] The chelating group bound to copper ions in the polymer mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com