Mercaptan thioetherification method

A technology of thiol thioether and alcohol thioether, applied in the field of reducing thiol content in gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

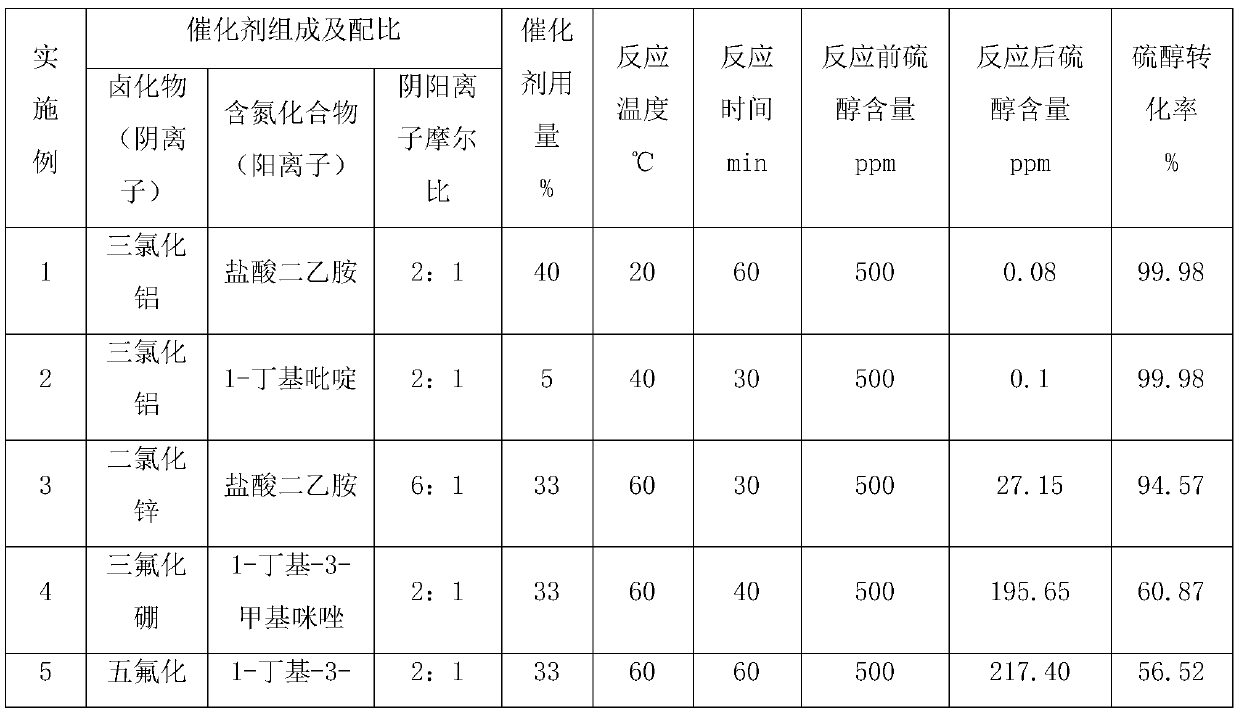

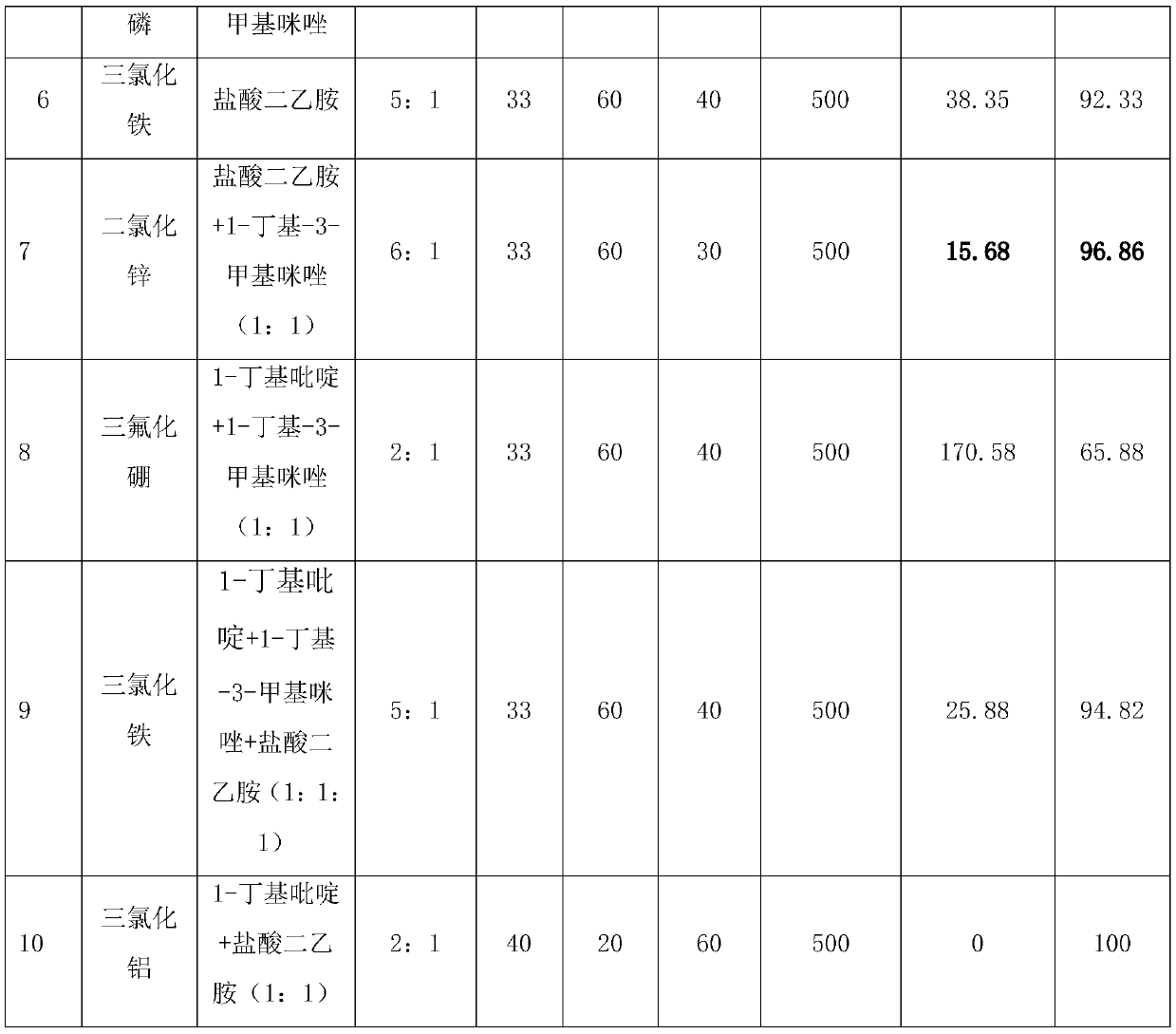

Examples

Embodiment 1

[0016] Take 5 grams of ionic liquid composed of anhydrous aluminum trichloride and diethylamine hydrochloride, wherein the molar ratio of anhydrous aluminum trichloride and diethylamine hydrochloride is 2:1, and put it into a three-port tank equipped with stirring and reflux devices. In the flask, 12.5 grams of mercaptan-containing hydrocarbon materials were added and reacted for 60 minutes at room temperature (20° C.). After the reaction, samples were taken and analyzed. The results are shown in Table 1.

Embodiment 2

[0018] Get 5 grams of ionic liquid composed of anhydrous aluminum trichloride and 1-butylpyridine, wherein the molar ratio of anhydrous aluminum trichloride and diethylamine hydrochloride is 2:1, put it into a mixing and reflux device In the three-necked flask, add 100 grams of mercaptan-containing hydrocarbon materials, and react at 40° C. for 30 minutes. After the reaction, samples are taken for analysis. The results are shown in Table 1.

Embodiment 3

[0020] Get 5 grams of ionic liquid composed of zinc dichloride and diethylamine hydrochloride, wherein the molar ratio of zinc dichloride and diethylamine hydrochloride is 6:1, put it into a three-necked flask equipped with a stirring and reflux device, add 15 grams of mercaptan-containing hydrocarbon materials were reacted at 60° C. for 30 minutes, and samples were taken for analysis after the reaction. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com