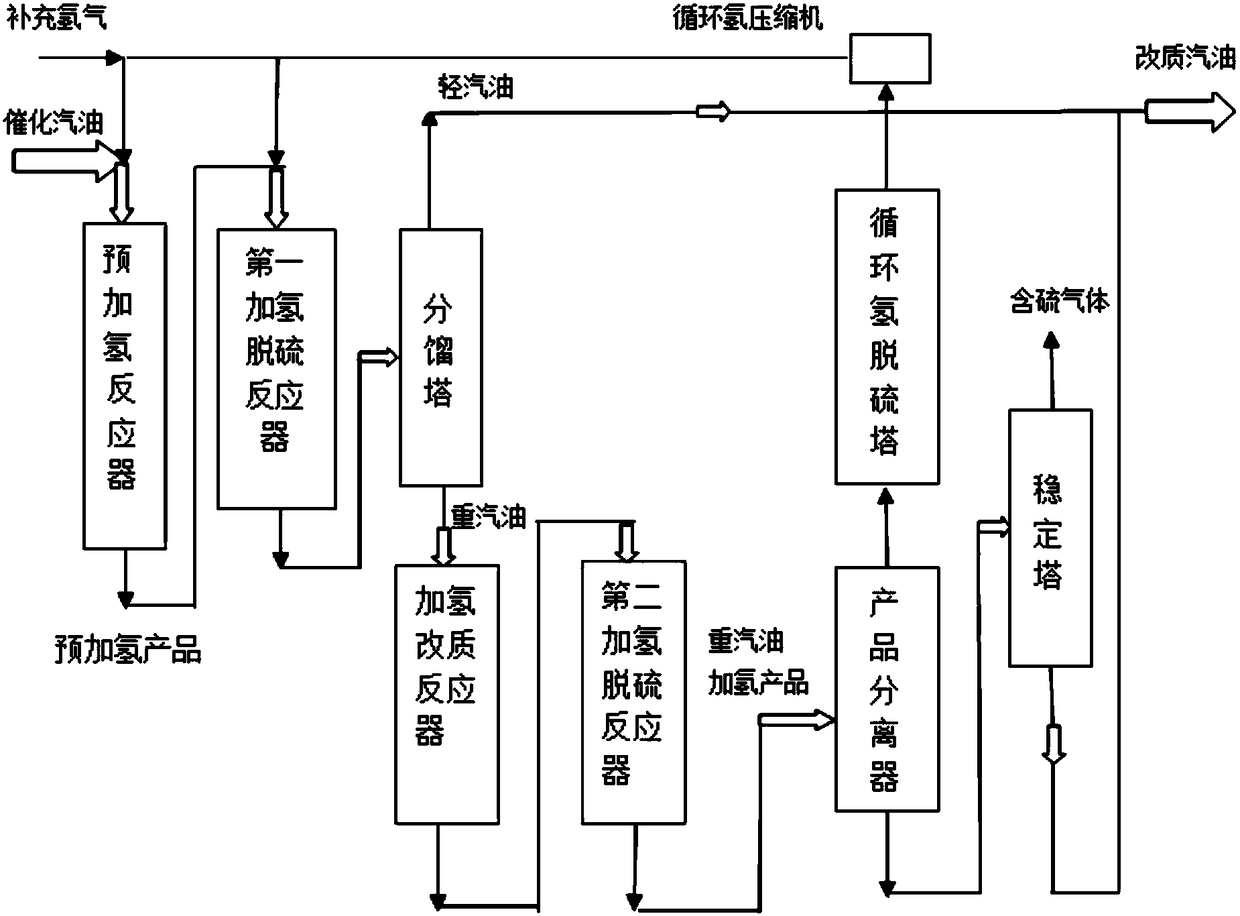

A method for hydrogenation and upgrading of low-quality gasoline

A technology of hydrogenation reforming and low-quality gasoline, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of high olefin and sulfur content and lower octane number of modified gasoline, and achieve the content of diolefins Reduce, reduce mercaptan content, increase the effect of cutting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The raw material oil that embodiment 1 uses is identical with comparative example 1. Catalyzed gasoline is first heated at a hydrogen partial pressure of 2.2Mpa, a reaction temperature of 110°C, and a volumetric space velocity of 3.0h -1 , Under the condition of hydrogen oil volume ratio of 10:1, catalyst A is used for pretreatment, and then mixed with hydrogen and then enters the first hydrodesulfurization reactor. -1 , Under the reaction conditions of 250:1 volume ratio of hydrogen to oil, use B catalyst to carry out hydrodesulfurization, and then enter the fractionation tower to cut into two components of light and heavy gasoline. 83°C, tower bottom temperature 207°C, heavy gasoline fraction accounts for 60% of the raw material. Heavy gasoline is first mixed with hydrogen and enters the hydroreforming reactor at a hydrogen partial pressure of 2.0MPa, a reaction temperature of 370°C, and a volumetric space velocity of 1.22h -1 , Under the reaction conditions of 250:...

Embodiment 2

[0050] The raw material oil that embodiment 2 uses is identical with comparative example 1. Catalyzed gasoline is first heated at a hydrogen partial pressure of 2.2Mpa, a reaction temperature of 120°C, and a volumetric space velocity of 3.0h -1 , Under the condition of hydrogen oil volume ratio of 10:1, use catalyst A for pretreatment, then mix with hydrogen and enter the first hydrodesulfurization reactor. -1 , Under the reaction conditions of hydrogen oil volume ratio 300:1, use B catalyst to carry out hydrodesulfurization, and then enter the fractionation tower to cut into two components of light and heavy gasoline. 74°C, tower bottom temperature 201°C, heavy gasoline fraction accounts for 70% of the raw material. Heavy gasoline is first mixed with hydrogen and enters the hydroreforming reactor at a hydrogen partial pressure of 2.0MPa, a reaction temperature of 380°C, and a volumetric space velocity of 1.5h -1 , Under the reaction conditions of 300:1 volume ratio of hydro...

Embodiment 3

[0052] The raw material oil used in embodiment 3 is shown in the catalytic gasoline 2 listed in table 1. Catalyzed gasoline is first heated at a hydrogen partial pressure of 2.2Mpa, a reaction temperature of 120°C, and a volumetric space velocity of 3.0h -1 , Under the condition of hydrogen oil volume ratio of 10:1, use catalyst A for pretreatment, then mix with hydrogen and enter the first hydrodesulfurization reactor. -1 , Under the reaction conditions of hydrogen oil volume ratio 300:1, use B catalyst to carry out hydrodesulfurization, and then enter the fractionation tower to cut into two components of light and heavy gasoline. 74°C, tower bottom temperature 205°C, heavy gasoline fraction accounts for 65% of the raw material. Heavy gasoline is first mixed with hydrogen and enters the hydroreforming reactor at a hydrogen partial pressure of 2.0MPa, a reaction temperature of 380°C, and a volumetric space velocity of 1.5h -1 , Under the reaction conditions of 300:1 volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com