A shale oil staged reverse sequence hydrogenation process system

The technology of a process system and a hydrogenation system is applied in the field of a shale oil graded reverse-sequence hydrogenation process system, which can solve the problems of poor economy and high olefin content, achieve low equipment investment and operating energy consumption, short process flow, and slow down coking. side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

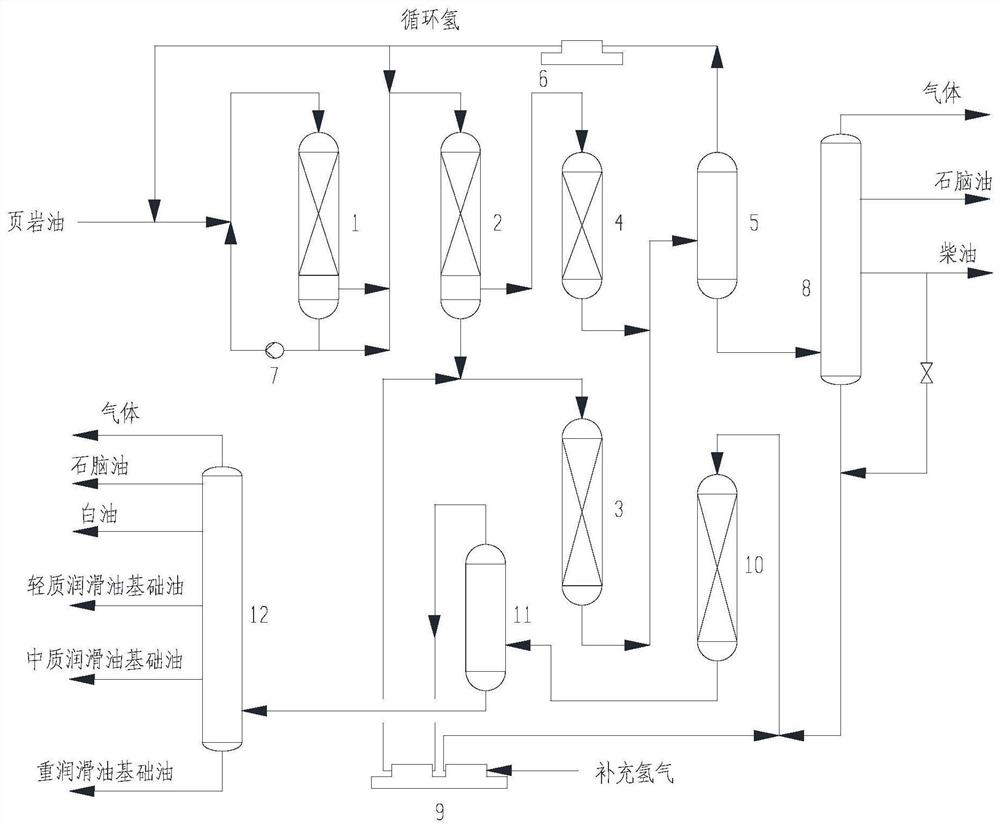

[0068] This embodiment provides a shale oil graded reverse-sequence hydrogenation process system, the structure of which is as follows figure 1 As shown, the process system comprises a one-stage hydrogenation system and a two-stage hydrogenation system connected in sequence;

[0069] The one-stage hydrogenation system includes an olefin saturation reactor, a desulfurization and denitrification reactor, a deep denitrification and dearomatization reactor, a gas-phase hydrogenation reactor, a first-stage hydrogenation separator and a first-stage hydrogenation product fractionation tower connected in sequence;

[0070] The two-stage hydrogenation system includes a hydroisomerization reactor, a two-stage hydrogenation separator, and a two-stage hydrogenation product fractionation column connected in sequence;

[0071] The hydrogenation tail oil outlet at the bottom of the first-stage hydrogenation product fractionation tower is connected with the reactant inlet of the hydroisomeriz...

Embodiment 2

[0082] This embodiment provides a shale oil graded and reversed hydrogenation process system using the shale oil graded and reversed hydrogenation process system provided in Embodiment 1, and the method includes:

[0083] The shale oil is mixed with circulating hydrogen and the returned liquid-phase olefin saturation reaction product, and then enters the olefin saturation reactor for hydrogenation reaction mainly based on the hydrogenation and saturation reaction of diolefins. The reaction product is subjected to gas-liquid separation at the bottom of the reactor, and One part is recycled to the olefin saturation reactor, and the other part is mixed with the gas-phase product and then enters the desulfurization and denitrogenation reactor to continue the olefin saturation reaction, and at the same time, the hydrorefining reaction mainly focuses on desulfurization, denitrogenation, deoxygenation and aromatics saturation. During the reaction process, a large amount of ammonia and...

Embodiment 3

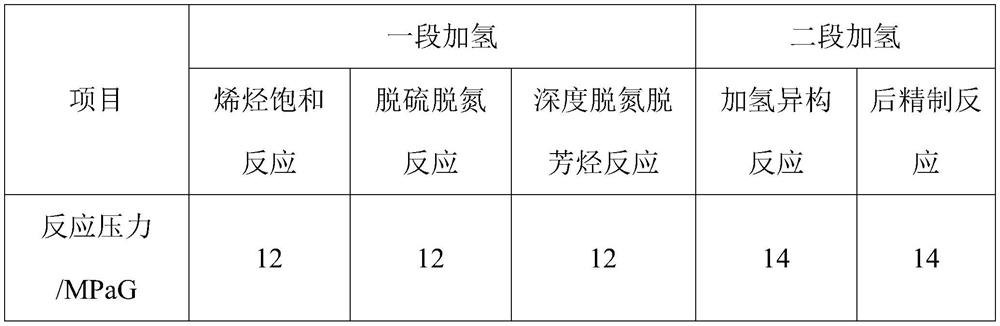

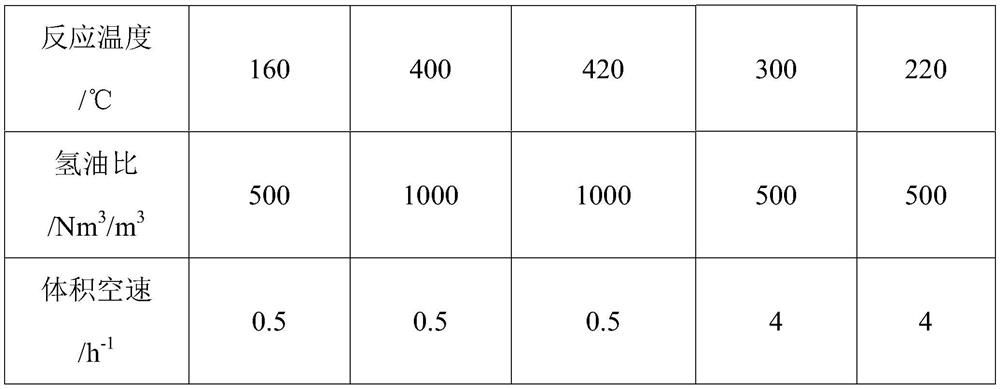

[0085] The shale oil was treated using the shale oil graded reverse hydrogenation equipment provided in Example 1 and the shale oil graded reverse hydrogenation method provided in Example 2, and the specific conditions are shown in Table 1.

[0086] Table 1

[0087]

[0088]

[0089] The mass ratio of the liquid phase to the shale oil that the olefin saturation reactor returns to the shale oil feed pipeline is 1:1;

[0090] The mass ratio of the hydrogenation tail oil and part of diesel oil separated by the first-stage hydrogenation product fractionation tower into the hydroisomerization reactor is 7.5:1.

[0091] The products of the one-stage hydrogenation product fractionator include naphtha and diesel.

[0092] The products of the two-stage hydrogenation product fractionator include naphtha, white oil, light lube base oil, medium lube base oil, and heavy lube base oil.

[0093] The quality index of naphtha products can reach S<0.5ppm, N<0.5ppm.

[0094] White oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com