Method of preparing low-molecular-weight styrene-acrylate emulsion copolymer

A technology of acrylate and emulsion copolymerization, which is applied in the fields of instruments, optics, electrography, etc., can solve the problems of high equipment cost, high energy consumption and high manufacturing cost, and achieve the effect of reducing mercaptan content, simple operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

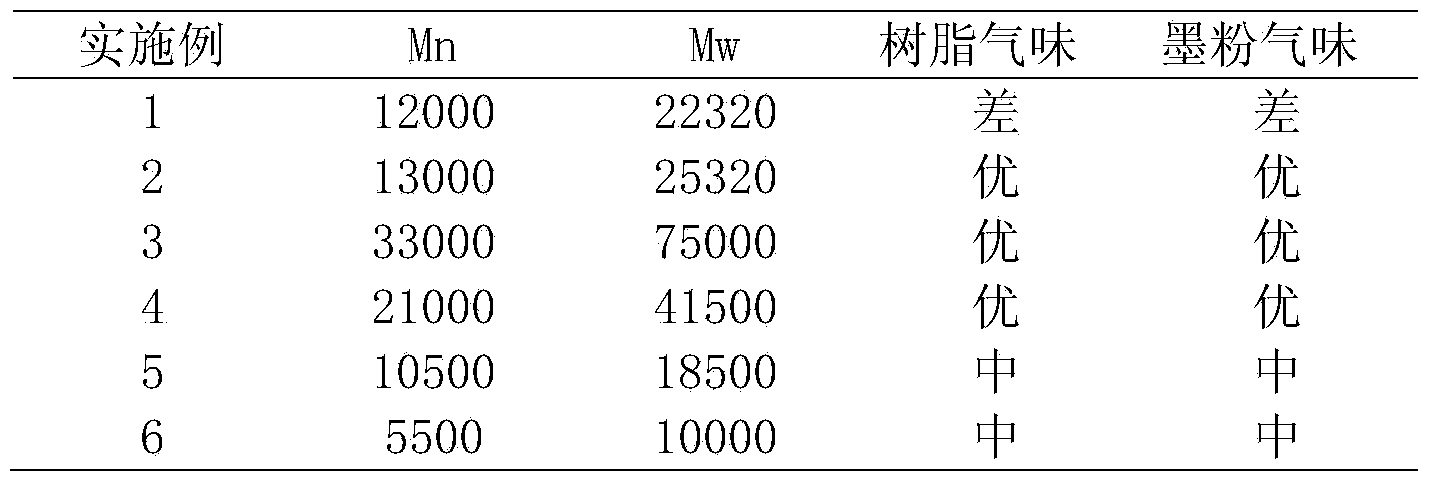

Examples

Embodiment 1

[0026] In a 5000ml four-neck reaction flask equipped with a stirring motor, reflux condenser, thermometer and dropping funnel, add 1820ml deionized water, 15.0g lauryl polyoxyethylene (10) ether acetic acid, adjust the pH value to 8.0 with ammonia water, add 135.0g styrene, 40.4g butyl acrylate, 3.6g hydroxyethyl methacrylate, 1.0g acrylic acid and 3.6g n-dodecanethiol, start stirring, heat the mixture to 85°C, add 15.0g concentration of 10% Aqueous ammonium persulfate solution was reacted for 1 hour to prepare seed emulsion. Then 1215.0g of styrene, 363.6g of butyl acrylate, 32.4g of hydroxyethyl methacrylate, 9.0g of acrylic acid and 32.4g of n-dodecanethiol were mixed evenly, and another 35.0g of lauryl polyoxyethylene (10) ether acetic acid Dissolve in 700ml of deionized water, adjust the pH value to 8.0 with ammonia water, add 225g of 5% ammonium persulfate aqueous solution, and stir the above-mentioned monomer, chain transfer agent, emulsifier and initiator aqueous solut...

Embodiment 2

[0030] In a 5000ml four-neck reaction flask equipped with a stirring motor, reflux condenser, thermometer and dropping funnel, add 1820ml deionized water, 15.0g lauryl polyoxyethylene (10) ether acetic acid, adjust the pH value to 8.0 with ammonia water, add 135.0g styrene, 40.4g butyl acrylate, 3.6g hydroxyethyl methacrylate, 1.0g acrylic acid, 0.6g n-dodecanethiol, 7.2g carbon tetrachloride, start stirring, heat the mixture to 85°C, add 15.0 g of a 10% ammonium persulfate aqueous solution was reacted for 1 hour to prepare a seed emulsion. Then 1215.0g styrene, 363.6g butyl acrylate, 32.4g hydroxyethyl methacrylate, 9.0g acrylic acid, 5.4g n-dodecanethiol, 64.8g carbon tetrachloride were mixed evenly, and another 35.0g lauryl alcohol Dissolve oxyethylene (10) ether acetic acid in 700ml of deionized water, adjust the pH value to 8.0 with ammonia water, add 225g of 5% ammonium persulfate aqueous solution, and stir the above monomer, chain transfer agent, emulsifier and initiato...

Embodiment 3

[0035] In a 5000ml four-neck reaction flask equipped with a stirring motor, reflux condenser, thermometer and dropping funnel, add 1820ml deionized water, 15.0g lauryl polyoxyethylene (10) ether acetic acid, adjust the pH value to 8.0 with ammonia water, add 135.0g styrene, 40.4g butyl acrylate, 3.6g hydroxyethyl methacrylate, 1.0g acrylic acid and 18g carbon tetrachloride, start stirring, heat the mixture to 85°C, add 15.0g concentration of 10% persulfuric acid Ammonium aqueous solution was reacted for 1 hour to prepare a seed emulsion. Then 1215.0g styrene, 363.6g butyl acrylate, 32.4g hydroxyethyl methacrylate, 9.0g acrylic acid and 162g carbon tetrachloride were mixed evenly, and 35.0g lauryl polyoxyethylene (10) ether acetic acid was dissolved in In 700ml of deionized water, adjust the pH value to 8.0 with ammonia water, add 225g of 5% ammonium persulfate aqueous solution, and stir the above-mentioned monomer, chain transfer agent, emulsifier and initiator aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com