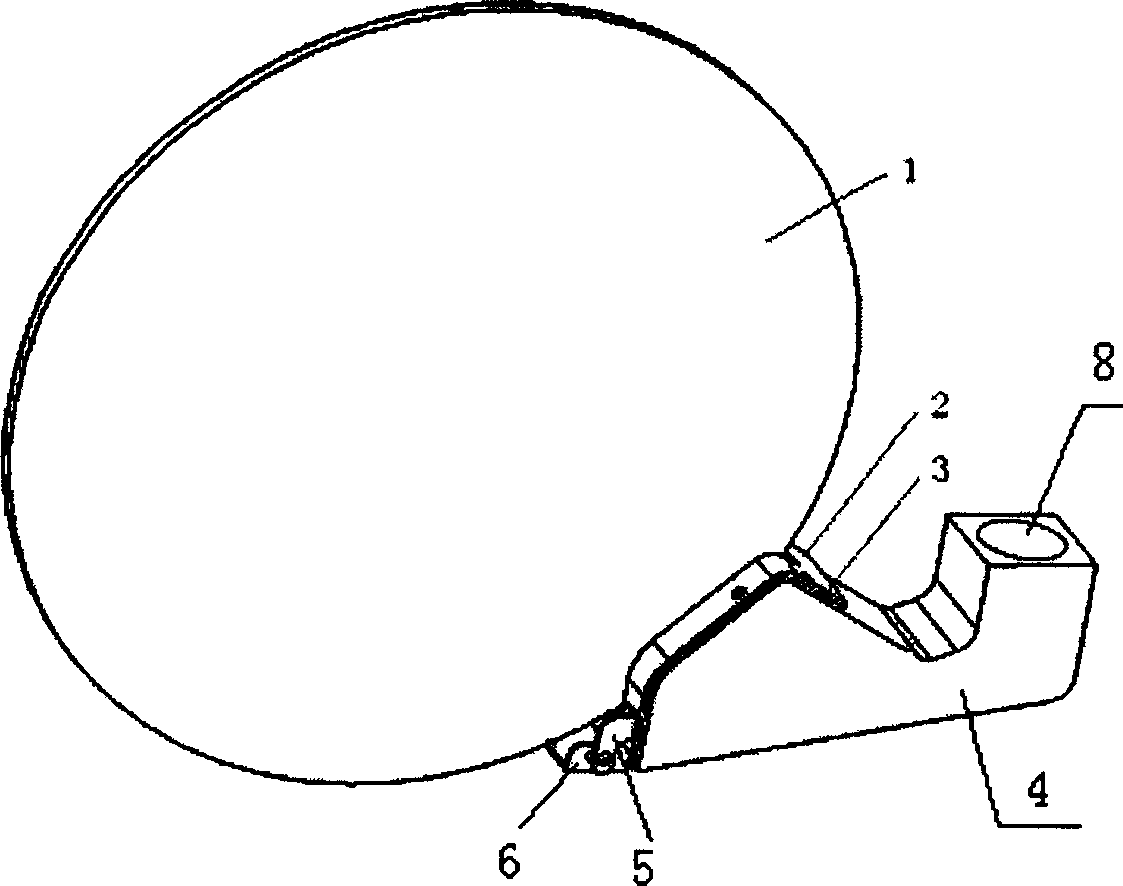

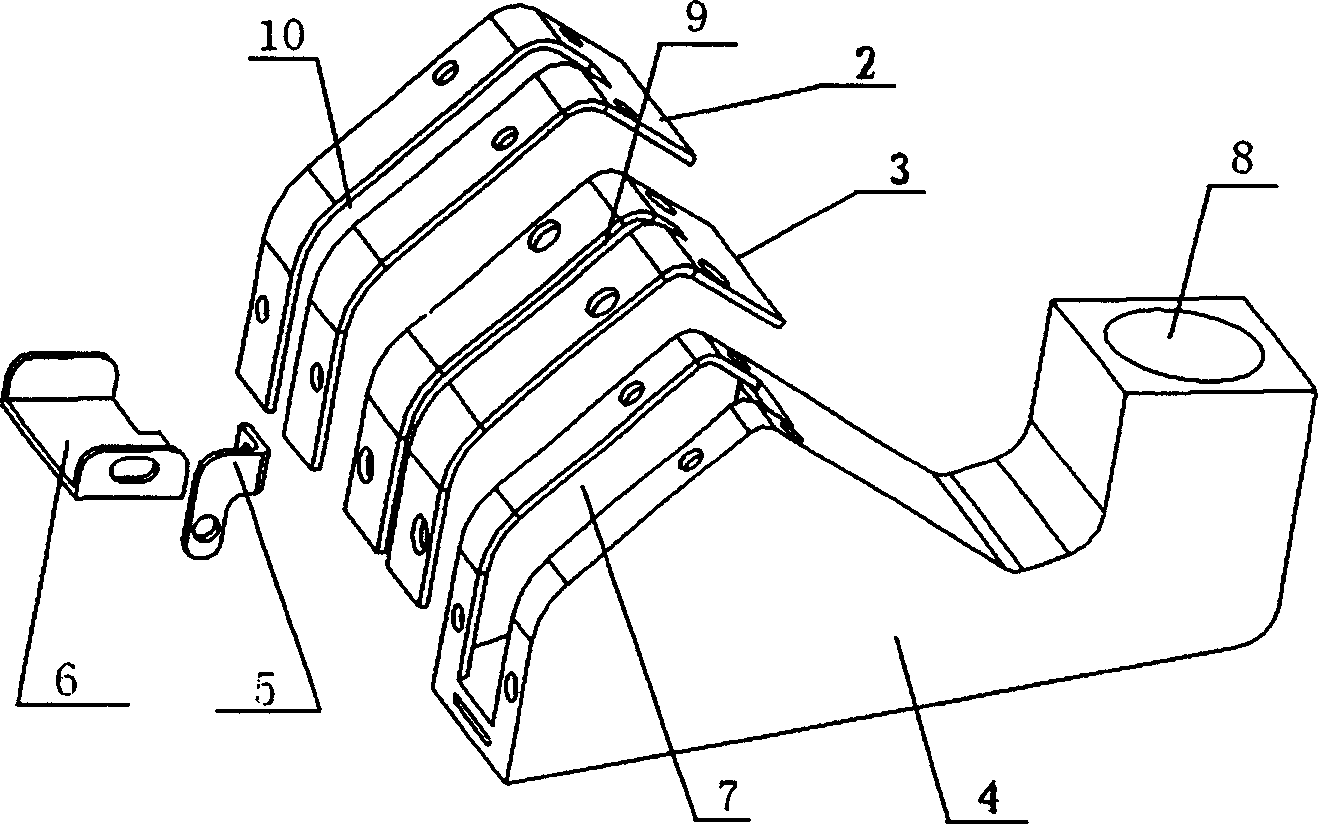

Closed Y type spray nozzle suitable for high speed and ultrahigh speed grinding

An ultra-high-speed grinding, closed technology, used in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., to improve durability, reduce deformation and vibration of grinding wheels, and solve blockage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] According to the drawings and the nozzle of the present invention with the above-mentioned structure, the nozzle body 4 is made of steel material, the main injection port 7 port and the horizontal plane form an angle of 15°, and the flexible mask 3 is a plastic sheet. The equipment and instrument that a kind of implementation scheme adopts have:

[0029] Machine tool: 314m / s ultra-high speed surface grinding test bench;

[0030] Grinding wheel: Electroplated CBN grinding wheel with a diameter of 350mm;

[0031] Workpiece material: 45#;

[0032] Grinding parameters:

[0033] a. Wheel speed (m / s): 60, 90, 120, 150;

[0034] b. Table feed speed: 2mm / min;

[0035] c. Grinding depth (mm): 0.01, 0.03, 0.05, 0.1, 0.15, 0.2;

[0036] d. Liquid supply pump pressure (MPa): 1, 5, 10;

[0037] e. Grinding method: reverse grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com