Super electrolyte resistant high water absorption resin and its prepn

A technology of electrolyte-resistant and water-absorbent resin, applied in the field of superabsorbent resin and its preparation, can solve the problems of low index, no water absorption of sodium chloride aqueous solution, etc., and achieve strong anti-mildew resistance, excellent electrolyte resistance and The effect of biodegradability, good economic benefits and socio-ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

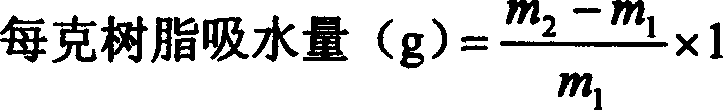

[0025] A super-strong electrolyte-resistant water-absorbing resin, the water absorption of the resin to distilled water is greater than 600 grams of water / gram of resin, the water absorption of tap water is greater than 250 grams of water / gram of resin, and the water absorption of 0.9% sodium chloride tap water solution is greater than 100 grams of water / grams of resin.

Embodiment 2

[0027] A method for preparing a super-strong electrolyte-resistant water-absorbing resin, comprising the following steps:

[0028] The first step is to mix water-soluble cellulose, acrylamide and cationic vinyl polymerized monomer in water, and the percentage of water-soluble cellulose to the total mass of water-soluble cellulose, acrylamide and cationic vinyl polymerized monomer is 5-30%, for example: 6%, 8%, 12%, 15%, 19%, 21%, 24%, 27.5%, acrylamide accounts for water-soluble cellulose, acrylamide and cationic vinyl polymer The percentage of the total mass of the three bodies is 20-65%, such as: 22%, 27%, 32%, 35%, 37%, 42%, 48%, 53%, 57%, 62%, cationic ethylene The percentage of polymerizable monomers in the total mass of water-soluble cellulose, acrylamide and cationic vinyl polymerizable monomers is 10-50%, for example, it can be 12%, 18%, 22%, 25%, 26%, 28%, 35%, 42%, 44%, 48%, after mixing, a mixed reaction system is formed, and substances other than water in the mixe...

Embodiment 3

[0033] Weigh 10 grams of carboxymethyl cellulose, 45 grams of acrylamide, 55 grams of methacryloyloxyethyltrimethylammonium chloride and 0.4 grams of N, N'-methylene bisacrylamide, add 180 ml of distilled water, fully Stir to dissolve, adjust the pH to 4 with 3% dilute hydrochloric acid solution, and then add 1.37 grams of ammonium persulfate and 0.63 grams of sodium bisulfite. Under the protection of nitrogen, react at 60°C for 45 minutes, cool the product, dry and pulverize to obtain a powdery water-absorbent resin.

[0034]The product (water-absorbing resin 1) in the present embodiment is a white powder, measured by tea bag weighing method, every gram of resin absorbs 602 grams of distilled water, 257 grams of tap water, and 112 grams of water absorption to 0.9% sodium chloride aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com