Carrier for olefin polymerization catalyst and its preparation method and its uses in preparing olefin polymerization catalyst

A technology of olefin polymerization and catalyst, which is applied in the carrier field of olefin polymerization catalysts, and can solve problems such as insufficient carrier alcohol content, complicated carrier process, and difficulty in preparing spherical carriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a) preparation of magnesium chloride solution: after passing through N 2 Add 200mL of dehydrated ethanol to the fully replaced 350mL reactor with stirring, and add 20g of anhydrous magnesium chloride while stirring at room temperature, control the adding speed of magnesium chloride, and keep the system temperature below 40°C. , the temperature of the mixed system was raised to 70°C, and kept at this temperature for 4 hours to obtain a uniform MgCl 2 ethanol solution.

[0034] b) Spray drying: This experiment was carried out by (Buchi Mini B-290 spray-drier). Use a peristaltic pump to a) the MgCl obtained in the step 2 The solution is introduced into the two-fluid nozzle through the pipe, and atomized into the drying chamber. Control feed liquid and spray gas N 2 The flow rates are 8mL / min and 1400L / h respectively, and the spray gas temperature is room temperature. Carrier gas N 2 The flow rate is controlled at 11000L / min, the inlet temperature of the instrument is...

Embodiment 2-3

[0037] Steps a and b are all the same as in Example 1, except that the amount of ethanol added in step c is changed to 2mL and 3mL, and the others are the same as in Example 1. Spherical supports with alcohol / magnesium ratios of 2.4 and 2.5, respectively, were obtained. See Tables 1 and 2 for the magnesium alkoxide content and particle size distribution analysis results of the samples.

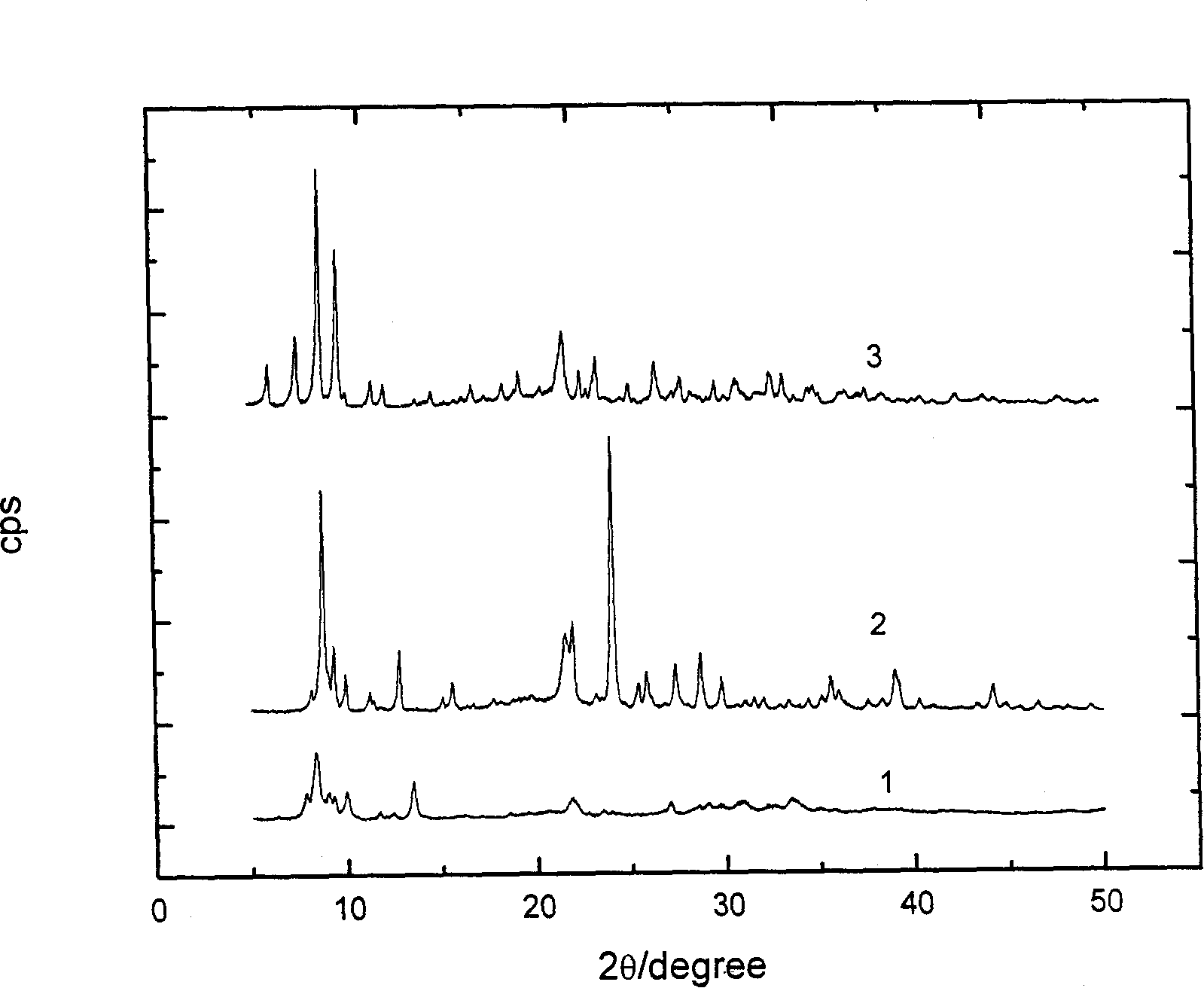

[0038] The spherical carrier of embodiment 3 has been carried out the test of X-diffraction, and its XRD spectrum is as figure 1 Spectrum 2 is shown.

Embodiment 4

[0040] a) preparation of mother liquor for magnesium chloride spray: after passing through N 2 Add 200mL of dehydrated ethanol to a fully replaced 350mL reactor with stirring, and add 17g of anhydrous magnesium chloride while stirring at room temperature, and control the adding speed of magnesium chloride to keep the system temperature below 40°C. , the temperature of the mixed system was raised to 70°C, and kept at this temperature for 4 hours to obtain a uniform MgCl 2 ethanol solution. Add 17g of smoky silica gel into the above solution under the condition of rapid stirring, continue to maintain the original temperature and stir rapidly for more than 1.5 hours, and obtain the mother liquor for spraying for later use.

[0041] b) Preparation of MgCl by spray drying 2 / SiO 2 Carrier: use a peristaltic pump to introduce the mother liquor obtained in step a) into a two-fluid nozzle through a pipeline, and atomize it into the drying chamber. Control feed liquid and spray gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com