Method and device for automatic on-line measurement of optical sheet warp

An optical thin plate and automatic measurement technology, applied to measuring devices, optical devices, instruments, etc., can solve problems such as poor quality control, manufacturing cost burden, waste of manpower, etc., to improve quality control capabilities and production capacity, and reduce manufacturing costs , The effect of increasing the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

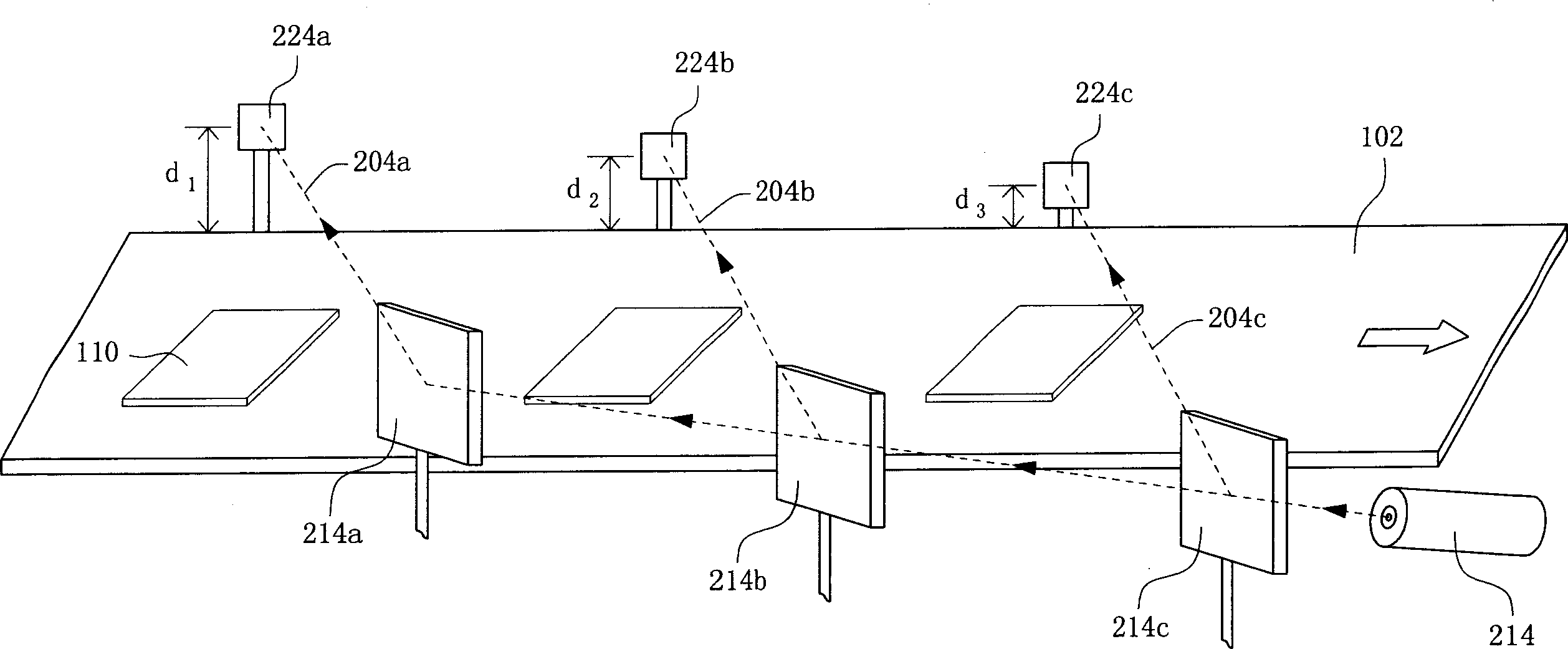

[0034] figure 1 A schematic diagram showing a preferred embodiment of the present invention. Such as figure 1 As shown, an optical sheet 110 , such as a polarizer, is moving on the conveyor belt 102 . In this preferred embodiment, at least one measuring light beam 104 is set on the conveyor belt 102 , and when the moving optical thin plate 110 blocks the measuring light beam 104 , it is determined that the optical thin plate 110 is warped. Since the conveyor belt 102 can be easily integrated into the known optical sheet manufacturing process, the device and method of this preferred embodiment can measure whether the optical sheet 110 is warped in real time on the production line.

[0035] In the preferred embodiment, the measurement beam 104 is generated by the light source 114 and received by the detector 124 . The light source 114 can be a laser light source or a common light source, such as helium-neon laser, diode laser, halogen lamp or other wavelengths of light that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com