Method for manufacturing far infrared-antistatic polyester fiber

A manufacturing method, polyester fiber technology, applied in the direction of conductive/antistatic filament manufacturing, single-component polyester artificial filament, short fiber formation, etc., can solve the problem of static electricity in far-infrared polyester fiber fabrics and limit the application field and other issues, to achieve the effect of long-term use, long-term use, market demand, and long-lasting functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Best practice:

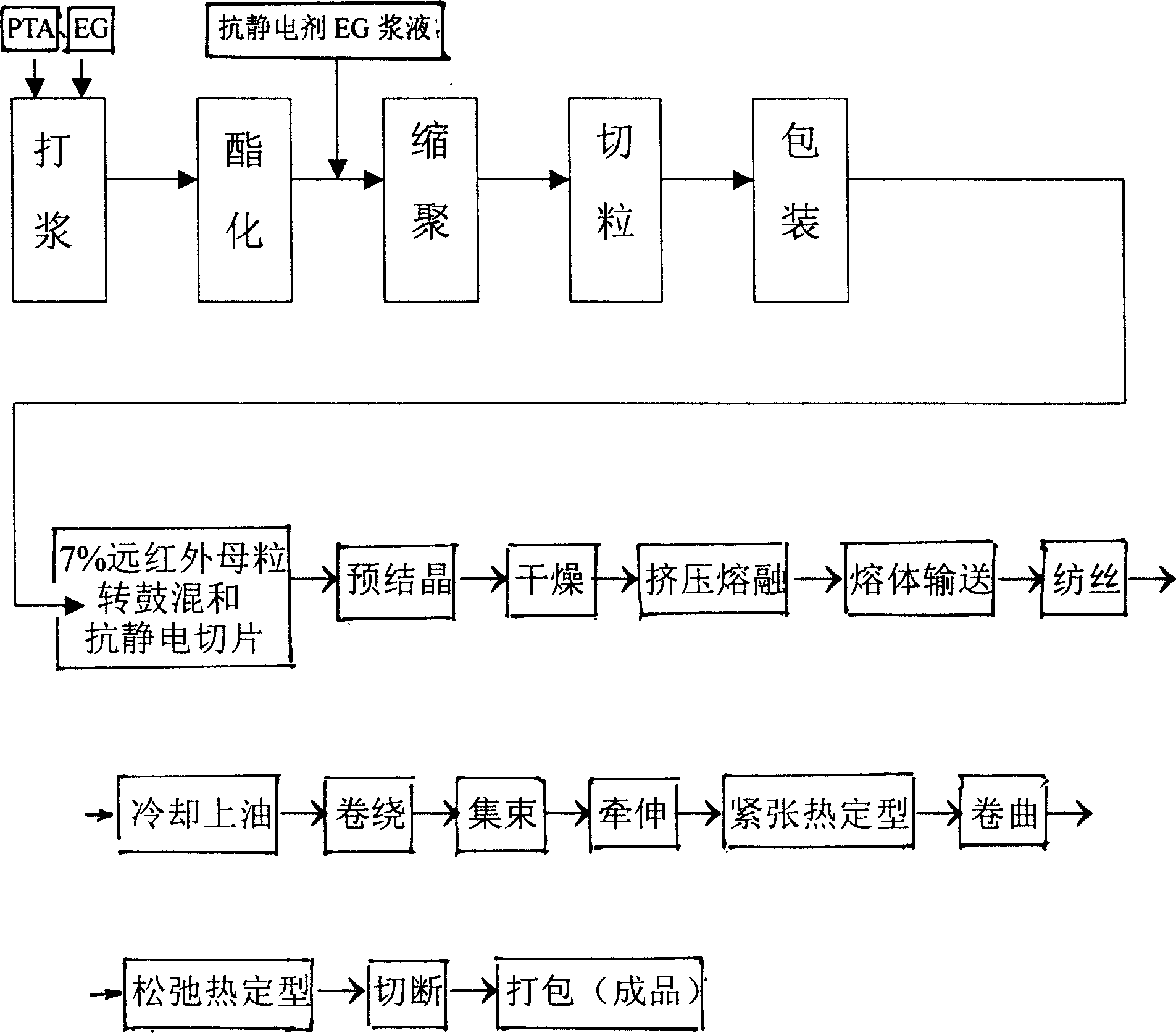

[0012] The present invention is applied in the 8,000-ton / year differential polyester polymerization unit and the 3,000-ton / year differential polyester staple fiber spinning unit of the Chemical Fiber Plant of Tianjin Petrochemical Company. The production method adopted is:

[0013] (1) The addition of inorganic antistatic powder is 3Wt% (to PET weight ratio);

[0014] (2) Inorganic antistatic powder is modulated into 20Wt% slurry with EG (ethylene glycol);

[0015] (3) After the esterification reaction is completed, the esterified BHET monomer is pressed into the polymerization kettle with nitrogen in the normal compression polymerization stage, and the EG (ethylene glycol) slurry of the inorganic antistatic powder is dropped into the polymerization kettle after completion;

[0016] (4) The far-infrared masterbatch of 7Wt% is mixed in the antistatic polyester chip and carries out blending and spinning.

[0017] The far-infrared-antistatic polyester st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com