Leaf alcohol synthesis method

A synthetic method and technology of leaf alcohol, which is applied in the field of high-grade flavor and fragrance leaf alcohol, can solve the problems of high production cost, dependence on import of products, failure of industrialization, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

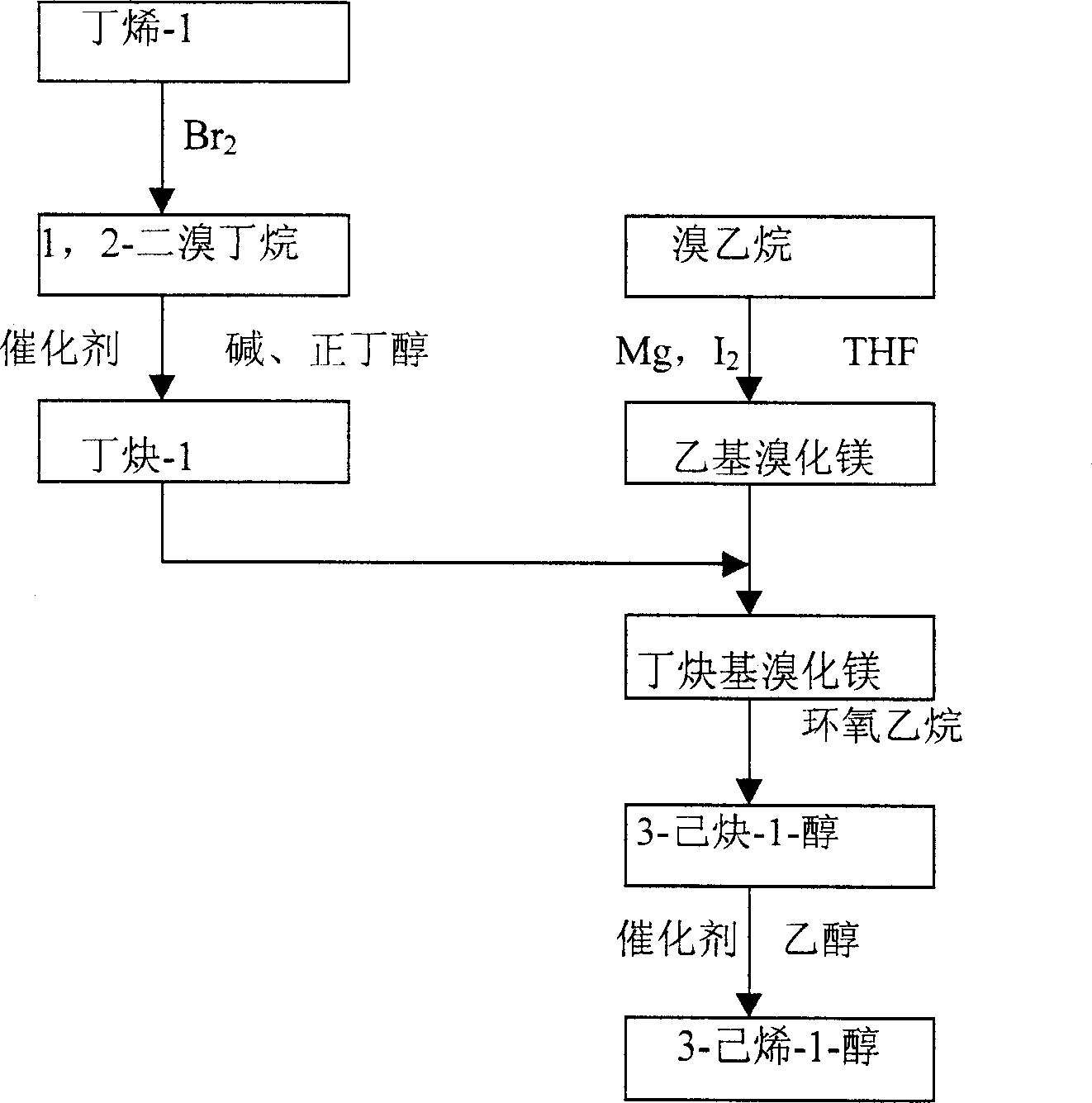

Method used

Image

Examples

Embodiment

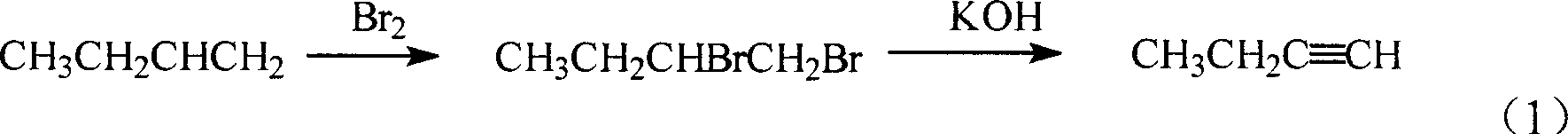

[0033] Step 1: Preparation of butyne-1

[0034] Add 200g of bromine into a 500ml three-necked flask, and pass through butene-1 in an ice-water bath until the color of the solution fades to obtain 1,2-dibromobutane, which is then distilled and purified for use.

[0035] In a 300ml three-neck flask with stirring and reflux condenser, add 100g of potassium hydroxide, heat to 130°C, slowly add 80g of 1,2-dibromobutane dropwise, and continuously produce butyne- 1 gas 15g, gas chromatography analysis content of more than 90%.

[0036] Step 2: Preparation of 3-hexyn-1-ol

[0037] Add 500ml of anhydrous tetrahydrofuran to a 1000ml three-neck flask with a stirring and reflux condenser connected to a nitrogen protection device, add 36g of magnesium chips and 5g of iodine under constant stirring, reflux, and nitrogen protection, and then slowly add bromoethane , to obtain ethylmagnesium bromide. Next, 80 g of butyne-1 prepared in step 1 was passed through at normal temperature and nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com