Sludge drying and resource disposal process

A sludge drying and sludge technology, applied in sludge treatment, biological sludge treatment, sewage/sludge fertilizer, etc., can solve the problems of small land occupation, high product volume treatment cycle, high unit investment, high operating cost, etc. Achieve the effects of improving land utilization, improving fermentation efficiency, and reducing dehydration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

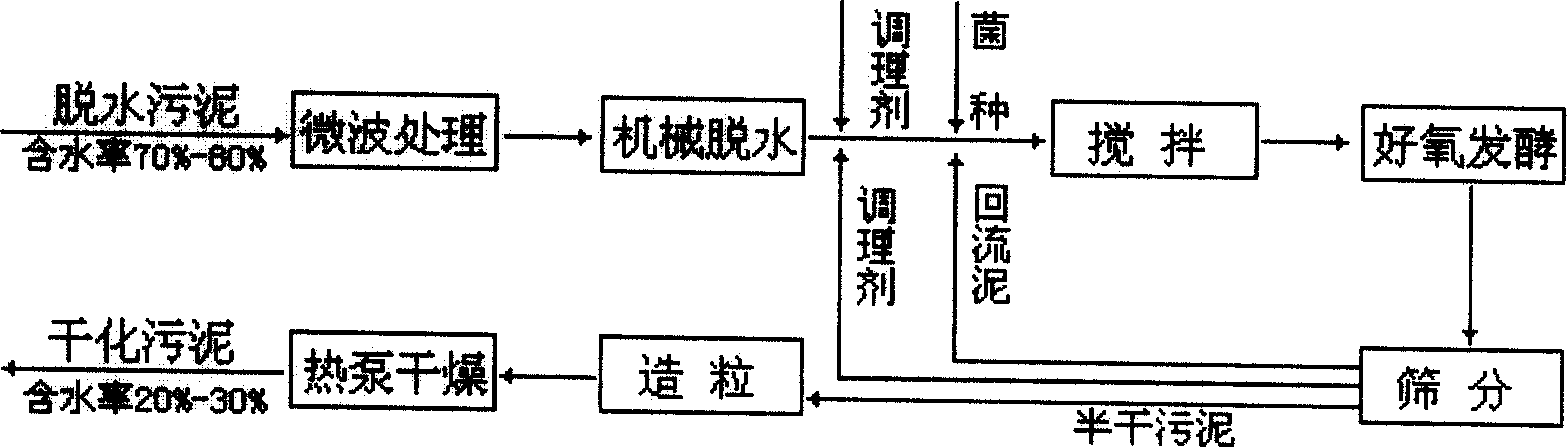

[0034] Processing technology of the present invention carries out according to the following steps:

[0035] (1) put the sludge of urban sewage treatment plant with a moisture content of 80% into a belt-type industrial microwave processor for pretreatment of wall breaking, disinfection and sterilization, and the treatment time is 3-5 minutes;

[0036] (2) put the pretreated sludge into a belt filter press for dehydration treatment, and the moisture content of the sludge can be reduced to 65%;

[0037] (3) Add special strains (0.1%), reflux sludge (10%) and conditioner (accounting for 30%) to the dehydrated sludge in a certain proportion to form a fermentation material, and use a large Stir with a mixer;

[0038] (4) Put the fermentation material into a closed sludge fermentation tower capable of continuous production for high-temperature aerobic fermentation. 5-7d fermented sludge is matured, the moisture content of the sludge is 40%, and the texture is loose and easy to bre...

Embodiment 2

[0044] Processing technology of the present invention carries out according to the following steps:

[0045] (1) put the sludge of urban sewage treatment plant with a moisture content of 80% into a belt-type industrial microwave processor for pretreatment of wall breaking, disinfection and sterilization, and the treatment time is 3-5 minutes;

[0046] (2) put the pretreated sludge into a belt filter press for dehydration treatment, and the moisture content of the sludge can be reduced to 60%;

[0047] (3) Add special strains (0.1%), reflux sludge (10%) and conditioner (accounting for 10%, particle size 20mm to 30mm) to the dehydrated sludge in a certain proportion to form a fermentation material, and stir it with a large mixer Uniform;

[0048](4) Put the fermentation material into a closed rotary fermenter that can be continuously produced for high-temperature aerobic fermentation. The diameter of the fermenter is 3m, the length is 30m, the speed is 0.2r / min, and the sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com