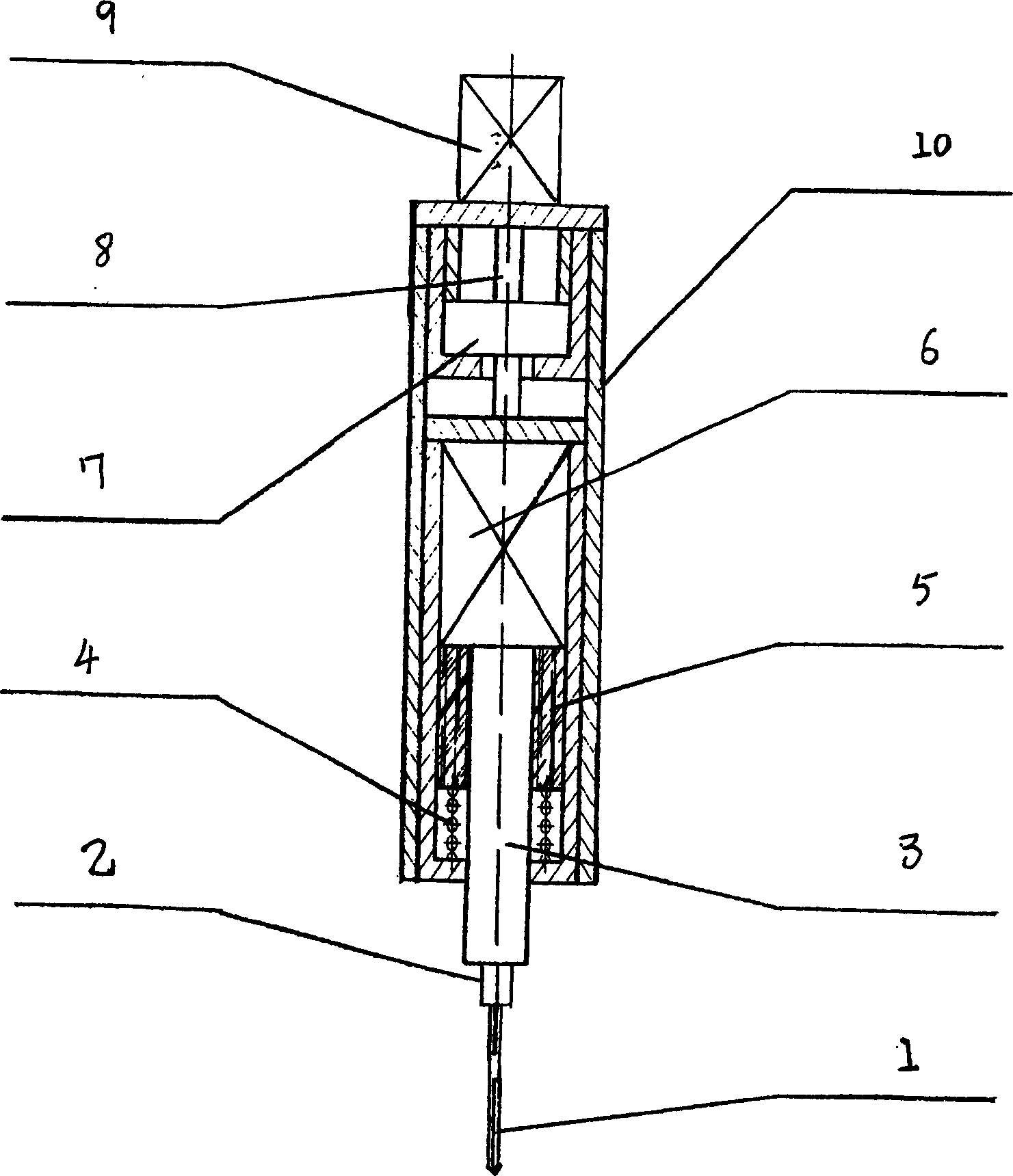

Boring machine and drilling method

A drilling method and technology of drilling machines, which are applied in drilling/drilling equipment, boring/drilling, components of boring machines/drilling machines, etc., can solve the problem that the hole accuracy and surface roughness cannot be guaranteed, and the design is difficult to achieve. requirements, extension of non-processing time, etc., to achieve the effect of reducing temperature, shortening processing time, and suppressing the decline of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0097] Processing example 1: processing diagram see Figure 23 , Figure 24

[0098] Part number: S10.55.041 Part material: 9Cr18

[0099] Material hardness: HB≤269 (GJB2294-95)

[0100] Process: 45, 50, 55, 60 processes

[0101] Tooling: self-made test tooling

[0102] Number of processed pieces: 12 pieces

[0103] Drill bit: Nanchang Carbide Factory production specifications φ0.45mm, φ0.60mm

[0104] Selection of processing parameters:

[0105] Spindle speed: 6000r / min; vibration frequency: 300Hz; feed rate: 3μm / r.

[0106] Program setting: initial height 20mm

[0107] G01 +1.5

[0108] G02-2

[0109] G03 +2.5

[0110] G04 -2.5

[0111] G05 +3

[0112] G06-3

[0113] G07 +3.5

[0114] G08 -3.5

[0115] G09 +4.0

[0116] G010 -4.0

[0117] G011 +4.5

[0118] G012 -4.5

[0119] G013 +5

[0120] G014-5

[0121] ...

example 2

[0128] Processing example 2: Part number: 5C12008; Part material: GH1140; Process: 15, 20; Number of processed pieces: 10 pieces

[0129] Drill bit: Nanchang Cemented Carbide Factory production specification φ0.6mm

[0130] Processing diagram see Figure 25

[0131] Selection of processing parameters:

[0132] Spindle speed: 6000r / min; Vibration frequency: 300Hz; Feed rate: 3μm / r

[0133] Program setting: initial height 12.5mm

[0134] G01 +2

[0135] G02-0000

[0136] Cooling and lubrication method: 20 # Manual oil injection

[0137] Test results: see Table 6

[0138]

serial number

Specimen

No

process

Drill Specifications

flow test

data

(cm 3 / s)

Test Description

1

1

15

0.6(1)

16.2

2

2

15

0.6(1)

16.25

3

3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com