Steam pressure sterilization pot

A sterilizing pot and pressure technology, which is applied to pressure cookers, cooking utensils, household utensils, etc., can solve the problems of sterilizing pot sealing problems that plague the industrial production of edible fungi, mechanical damage to sealing materials, cumbersome and time-consuming operations, etc., and achieve compact structure, Reduced labor intensity and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

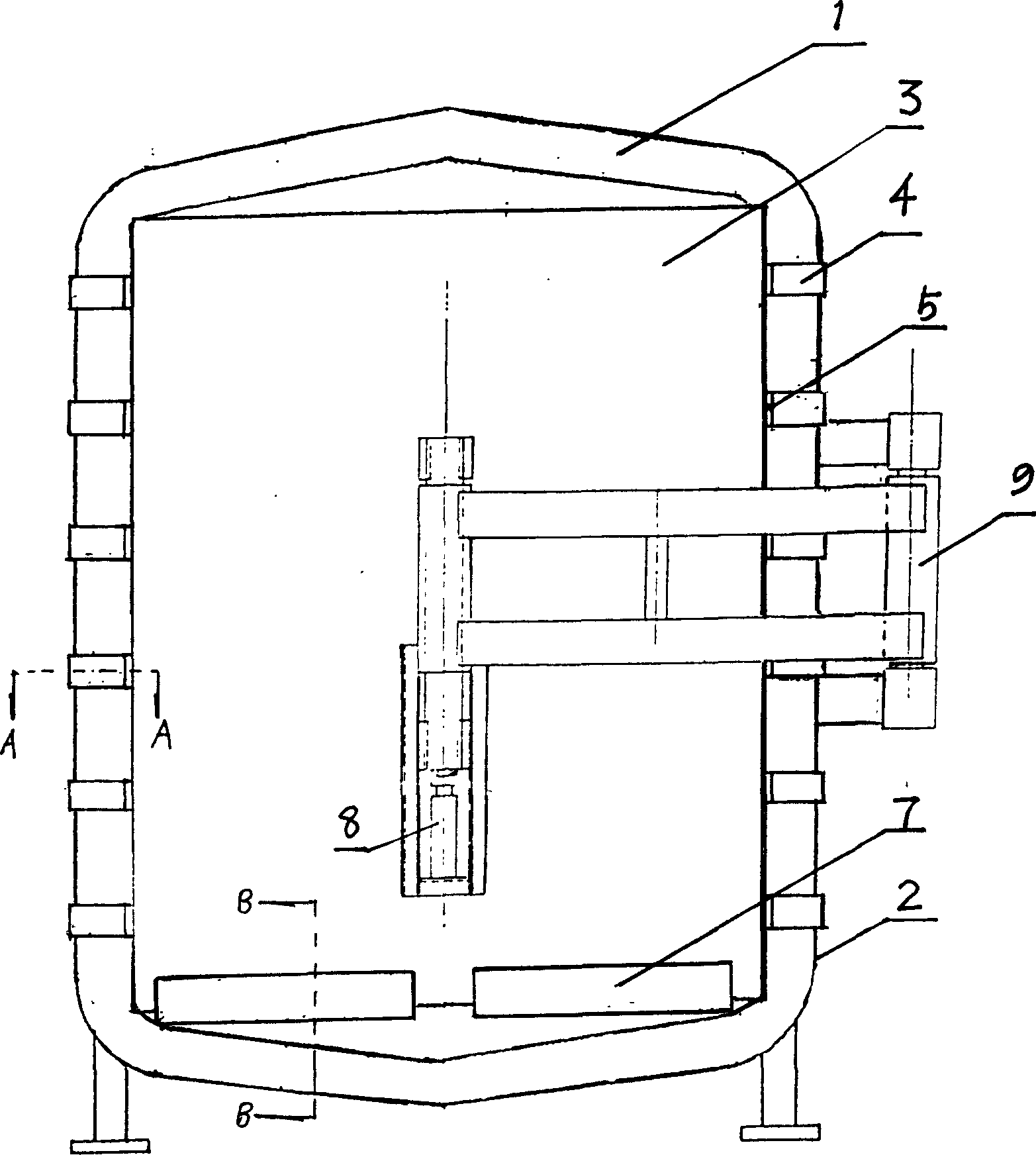

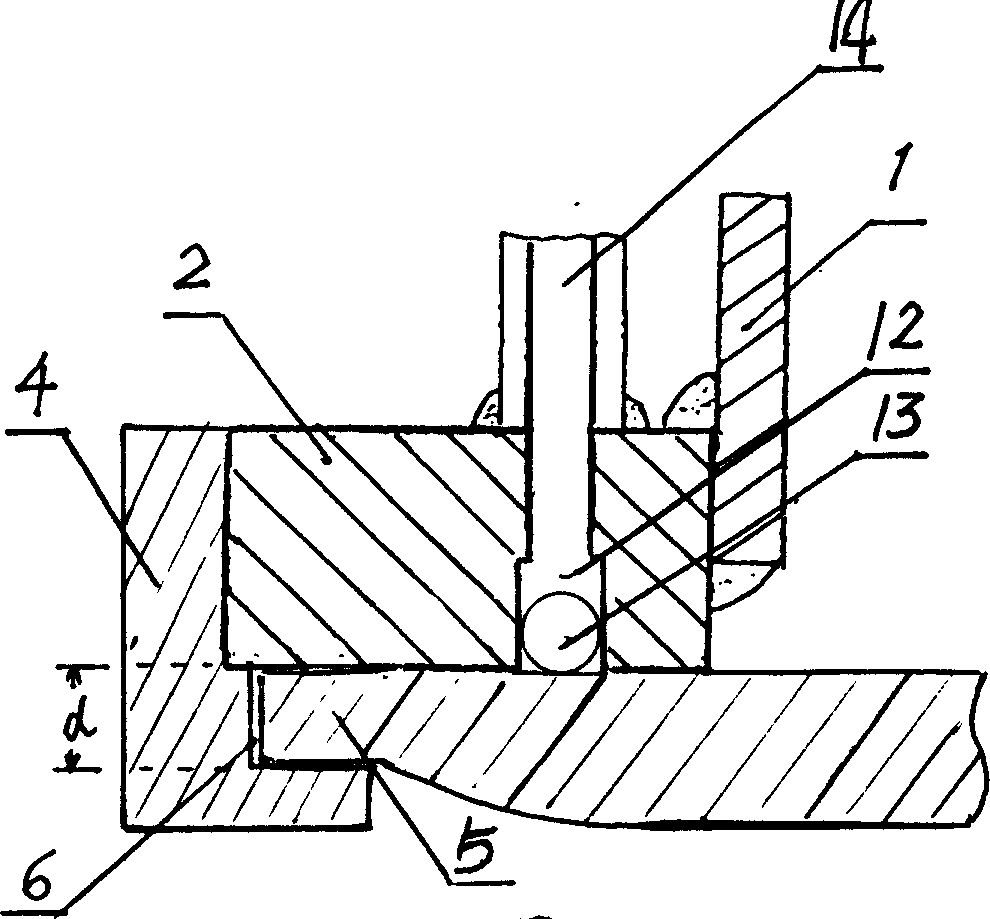

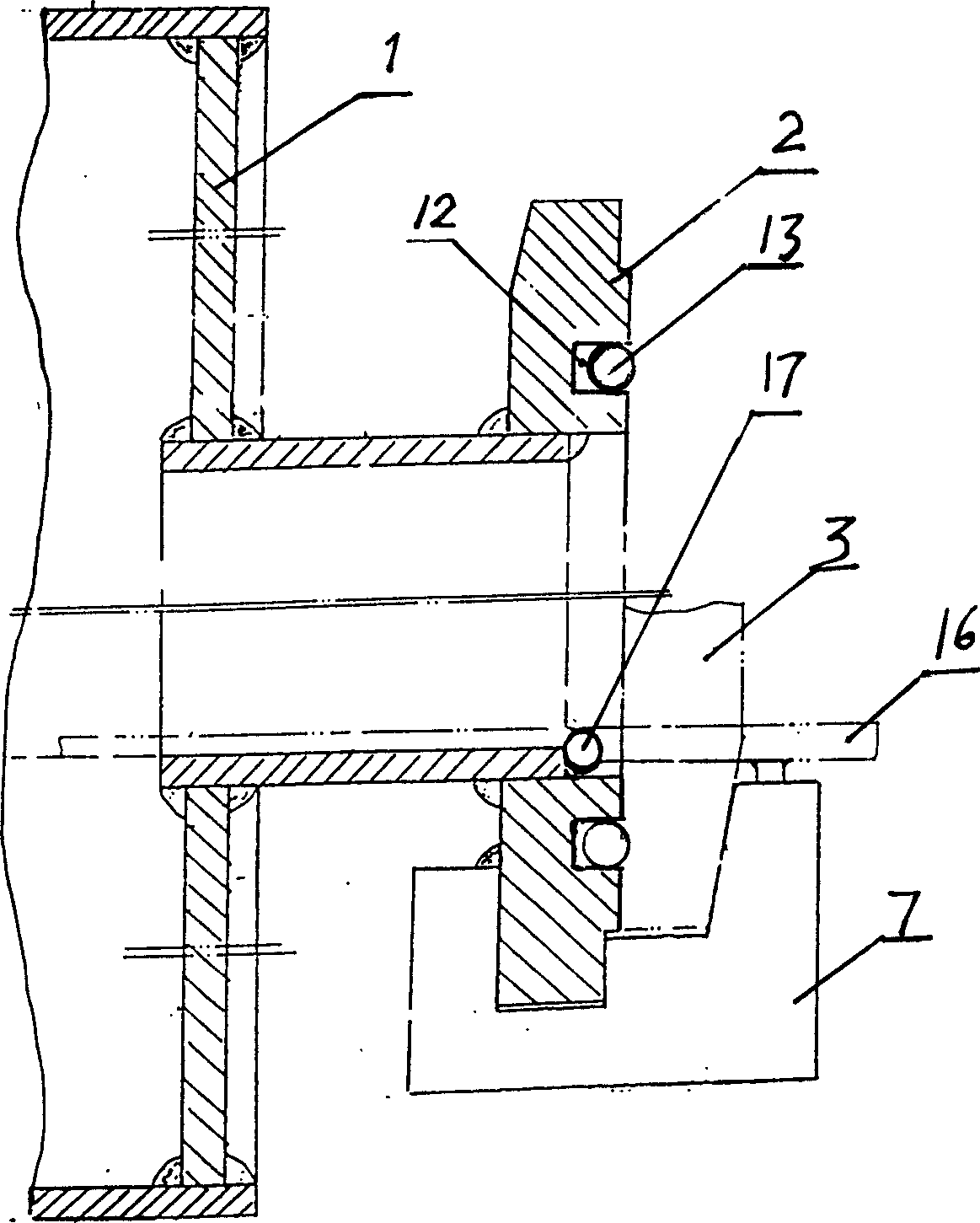

[0018] like figure 1 , 2 , Shown in 3, 4 and 5, 1 is a steam pressure sterilization pot body, generally several meters or more than ten meters long, and most of the width and height are more than two meters. 2 is a sealed door frame. There is a sealing groove 12 surrounding the sealing door frame 2 on the surface in contact with the sealing door 3. The cross-section is rectangular. The depth of the sealing groove 12 is larger than the width. The connection port 14 where the compressed air enters; the sealing groove 12 has an O-ring 13 , and the width of the sealing groove 12 matches the cross-sectional diameter of the O-ring 13 . The two edges of the sealed door frame 2 respectively have some fixed door buckles 4, evenly distributed; There are fixed front teeth 5 corresponding to the fixed door buckle 4 in the left and right sides of the sealed door 3, and its thickness is the same as that between the fixed door buckle 4 and the sealed door 3. The width d of the clamping pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com