Automatic deviation correcting device for upper belt surface and lower belt surface of conveyor

A technology of automatic deviation correction device and conveyor, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of scattering, tearing tape, deviation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

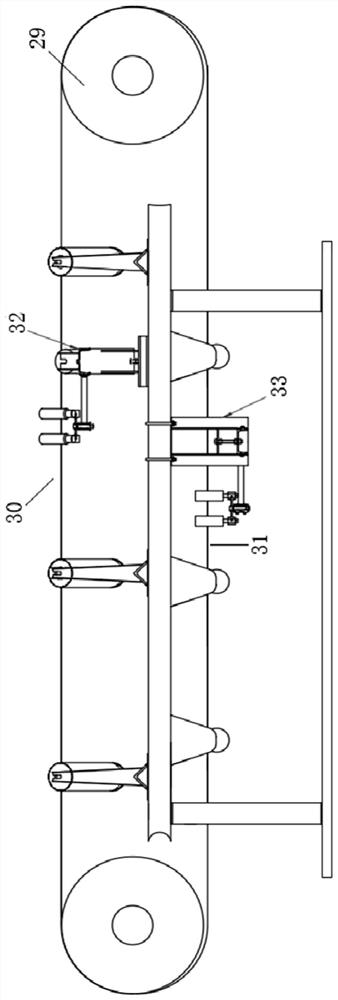

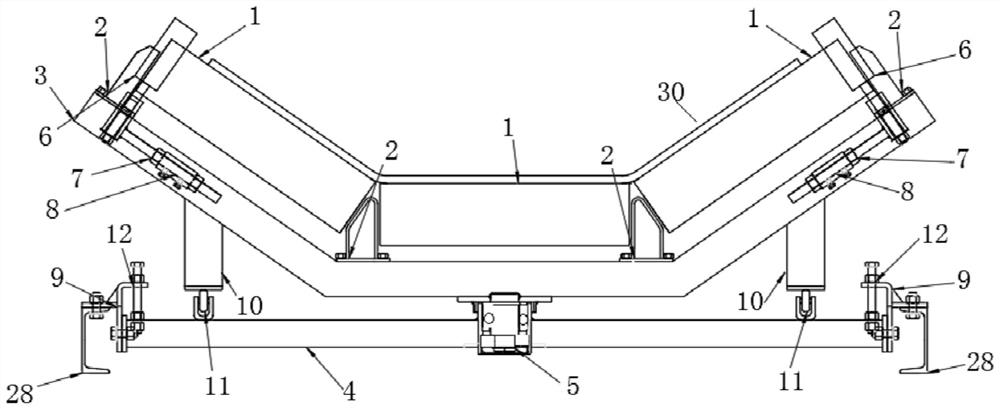

[0023] An automatic deviation correcting device for the upper belt surface and the lower belt surface of the conveyor of the present invention, the automatic deviation correction device for the upper belt surface of the conveyor is provided on the upper belt surface of the conveyor, and the lower belt surface of the conveyor is provided on the lower belt surface of the conveyor. The automatic deviation correction device for the belt surface on the conveyor includes three idler rollers, idler support seats, rotating upper beams, lower beams, rotating shafts, double detection rollers, double detection roller adjustment screw rods, and connecting rods. , a mounting plate, a support plate, a support wheel, and an adjusting screw, the three idlers are located below the upper belt surface, and the three idlers are installed on the roller supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com