Engine bearing failure testing and diagnosing method and failure detecting instrument

A technology of fault testing and diagnosis method, applied in auxiliary equipment of power plant on aircraft and vehicles, in the field of aero-engine maintenance and detection, which can solve the problems of aircraft flight safety, delay of engine repair time, wrong judgment, etc., which affect the quality of engine maintenance. Achieve significant effect, accurate judgment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

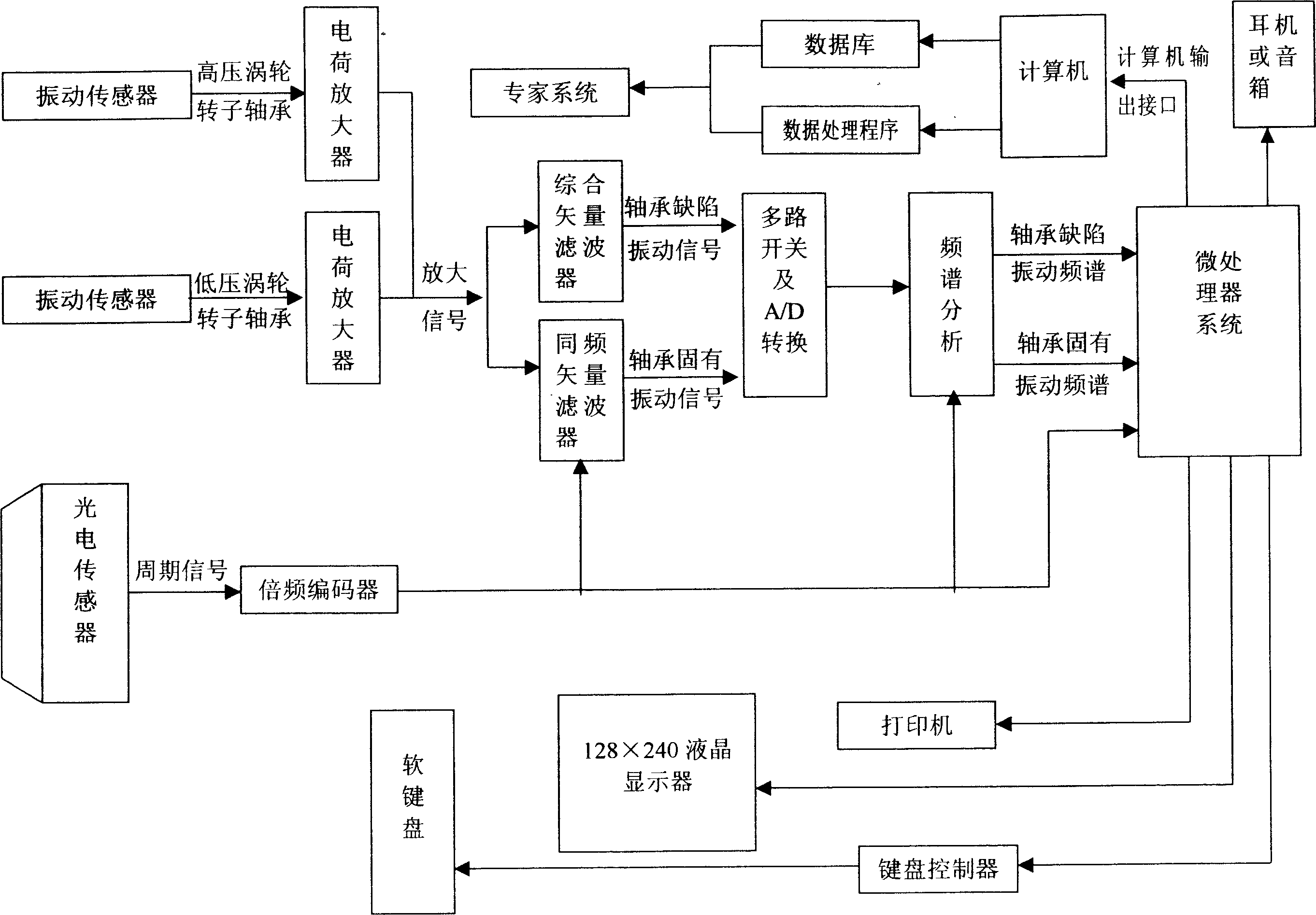

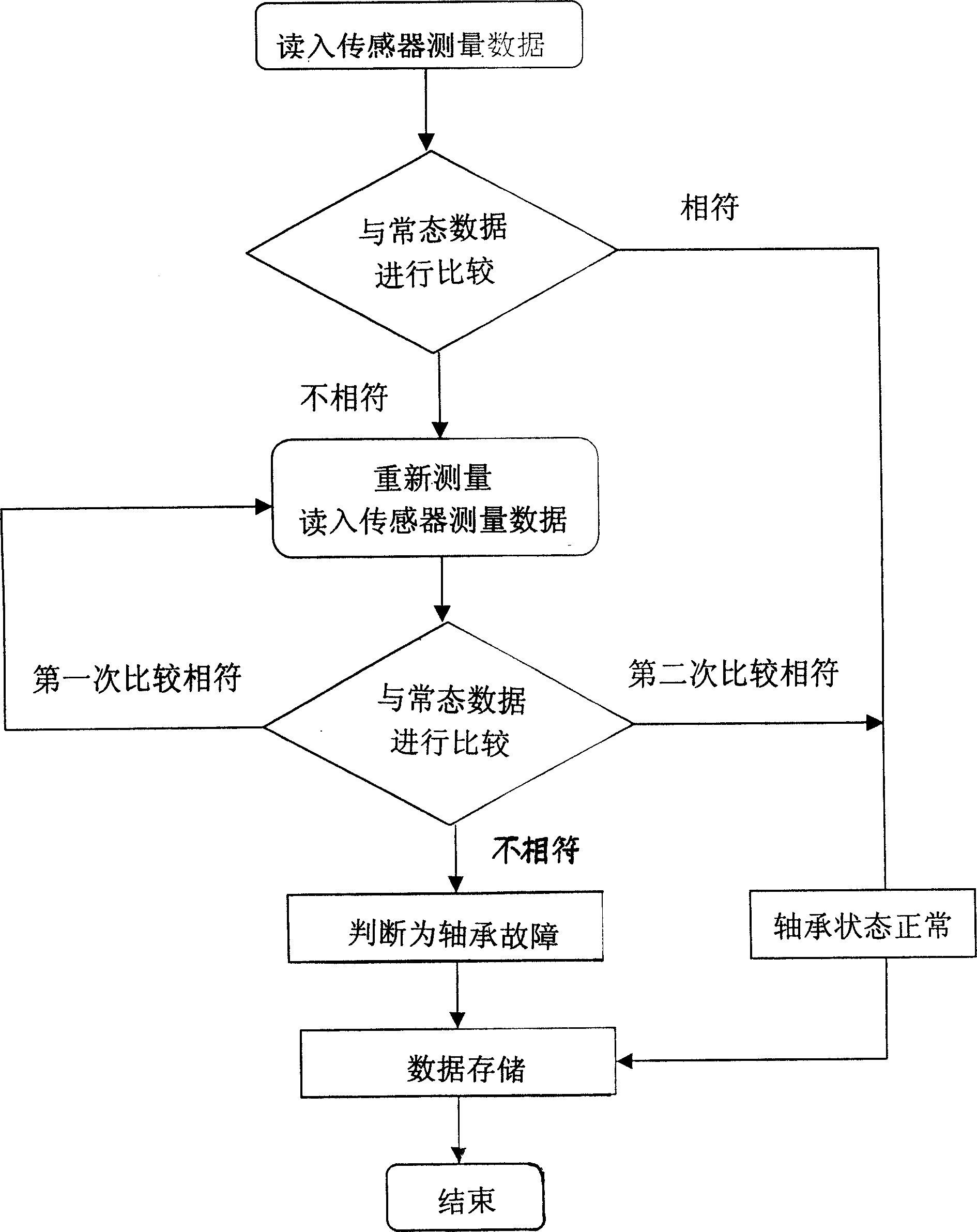

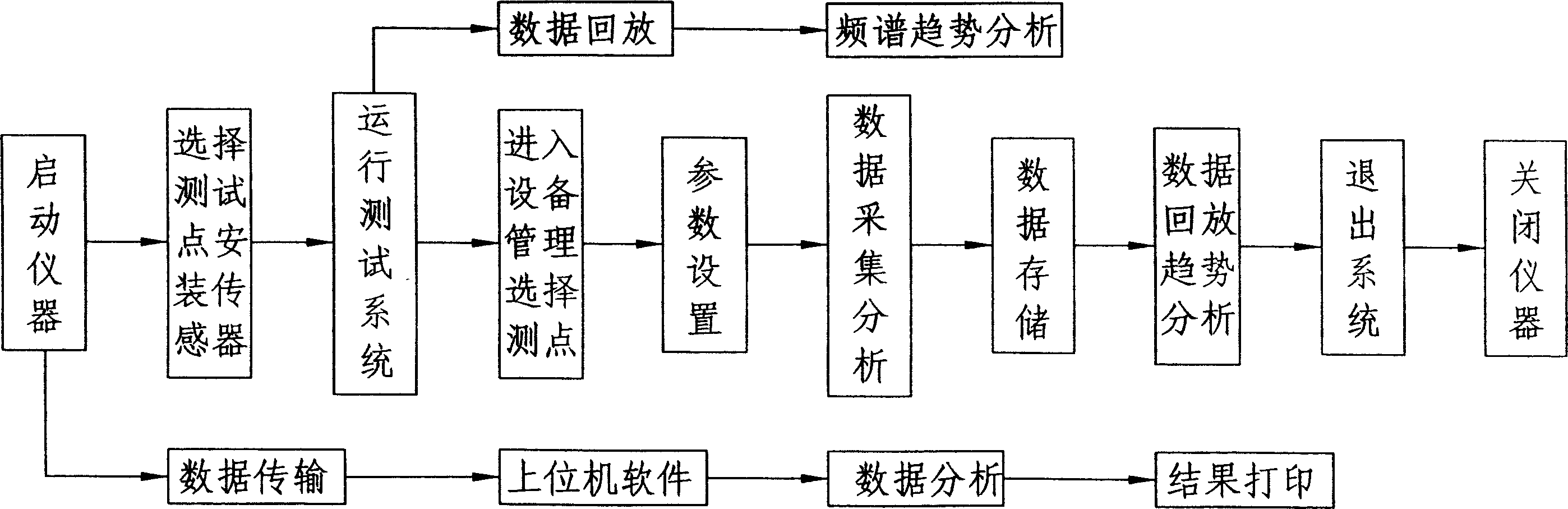

[0028] The content of the present invention will be further elaborated below in conjunction with the accompanying drawings of the description. The content of the present invention actually includes three parts, namely (1) a testing and diagnosing method for an aeroengine bearing fault; (2) an engine bearing fault detector and (3) a computer processing program for engine testing and diagnosis. When we describe the specific embodiment of the present invention, we will focus on (1) the structure of the engine bearing fault detector and (2) the actual operation process of using the detector to test and diagnose the engine bearing fault. In fact, the test and diagnosis method for bearing faults of the present invention will naturally be clearly understood through the description of the operation process.

[0029] The three parts provided by the present invention constitute a complete aeroengine bearing testing and diagnosing system, which is composed of hardware and software. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com