Mask patterns for semiconductor device fabrication and related methods and structures

A pattern and device technology, applied in semiconductor/solid-state device manufacturing, originals for optomechanical processing, photosensitive materials for optomechanical equipment, etc. The effect of resistance

Inactive Publication Date: 2010-08-25

SAMSUNG ELECTRONICS CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

According to this technology, silicon content can be limited, so it may be difficult to obtain sufficient resistance to dry etching

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

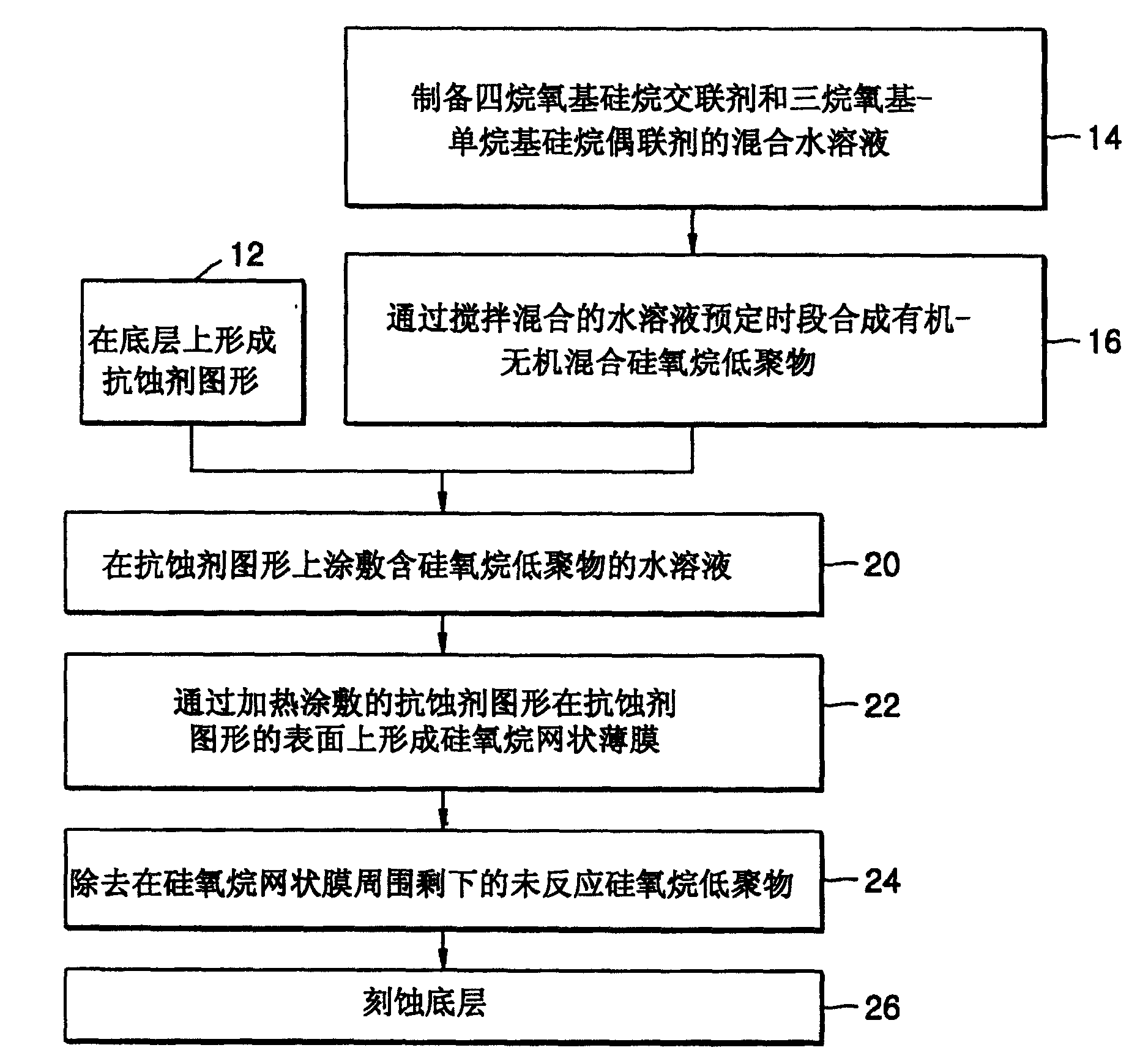

Methods of forming an integrated circuit device may include forming a resist pattern on a layer of an integrated circuit device with portions of the layer being exposed through openings of the resist pattern. An organic-inorganic hybrid siloxane network film may be formed on the resist pattern. Portions of the layer exposed through the resist pattern and the organic-inorganic hybrid siloxane network film may then be removed. Related structures are also discussed.

Description

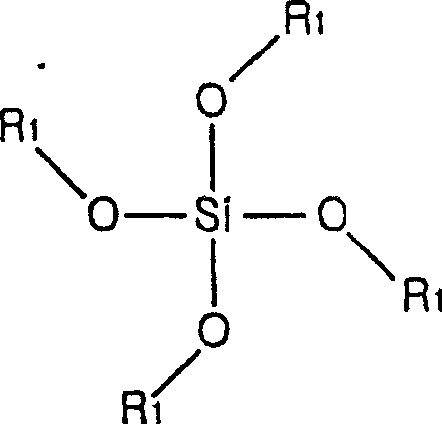

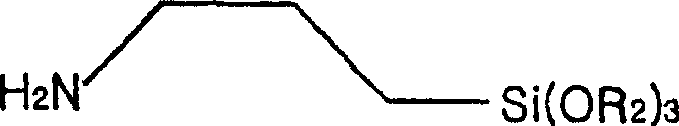

related application This application claims priority to Korean Patent Application No. 10-2004-0076349 filed with the Korean Intellectual Property Office on September 23, 2004, the disclosure of which is hereby incorporated by reference in its entirety. technical field The present invention relates to semiconductor device manufacturing, and more particularly to mask patterns and related methods and structures for semiconductor device manufacturing. Background technique In a conventional patterning process used in the manufacture of semiconductor devices, a photoresist pattern can be formed on a film to be etched (for example, a silicon film, a dielectric film, or a conductive film) for pattern formation. The film can be etched using the photoresist pattern as an etch mask to form a desired pattern. As the integration level of semiconductor devices increases, forming fine patterns including contact holes with smaller opening sizes or spaces with smaller widths requires sm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/004G03F7/039G03F7/075G03F7/09G03F1/70G03F1/80G03F7/40H01L21/027

CPCH01L21/0273H01L21/31144G03F7/405H01L21/0274G03F7/075

Inventor 夏政焕金贤友畑光宏禹相均

Owner SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com