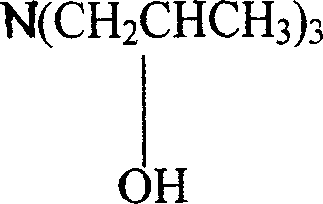

Use of tri-isopropanolamine in cement grinding aid

A technology of triisopropanolamine and cement grinding aid, which is applied in the field of cement additives and can solve the problems of high dependence on imports, poor strength in the later stage, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Each component is weighed by the following percentages by weight: 80% of triisopropanolamine, 8% of triethanolamine, 3% of lignosulfonate, 0.5% of alkylsulfonate, and 8.5% of water, and stir in the same container to make Thoroughly mix the cement grinding aid.

Embodiment 2

[0011] According to the weight percentage of the following components: 90% of triisopropanolamine, 4.5% of triethanolamine and 5.5% of water, weighed and mixed to obtain cement grinding aid.

Embodiment 3

[0013] According to the weight percentage of the following components: 88% of triisopropanolamine, 4.4% of triethanolamine, 2% of carboxylic acid, and 5.6% of water, weigh and mix to obtain the cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com