Dry method/ half dry method desulfurizer

A semi-dry desulfurization and desulfurization agent technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high desulfurization cost, high energy consumption, and large desulfurization equipment, and achieve good water absorption and equipment Small size and stable desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

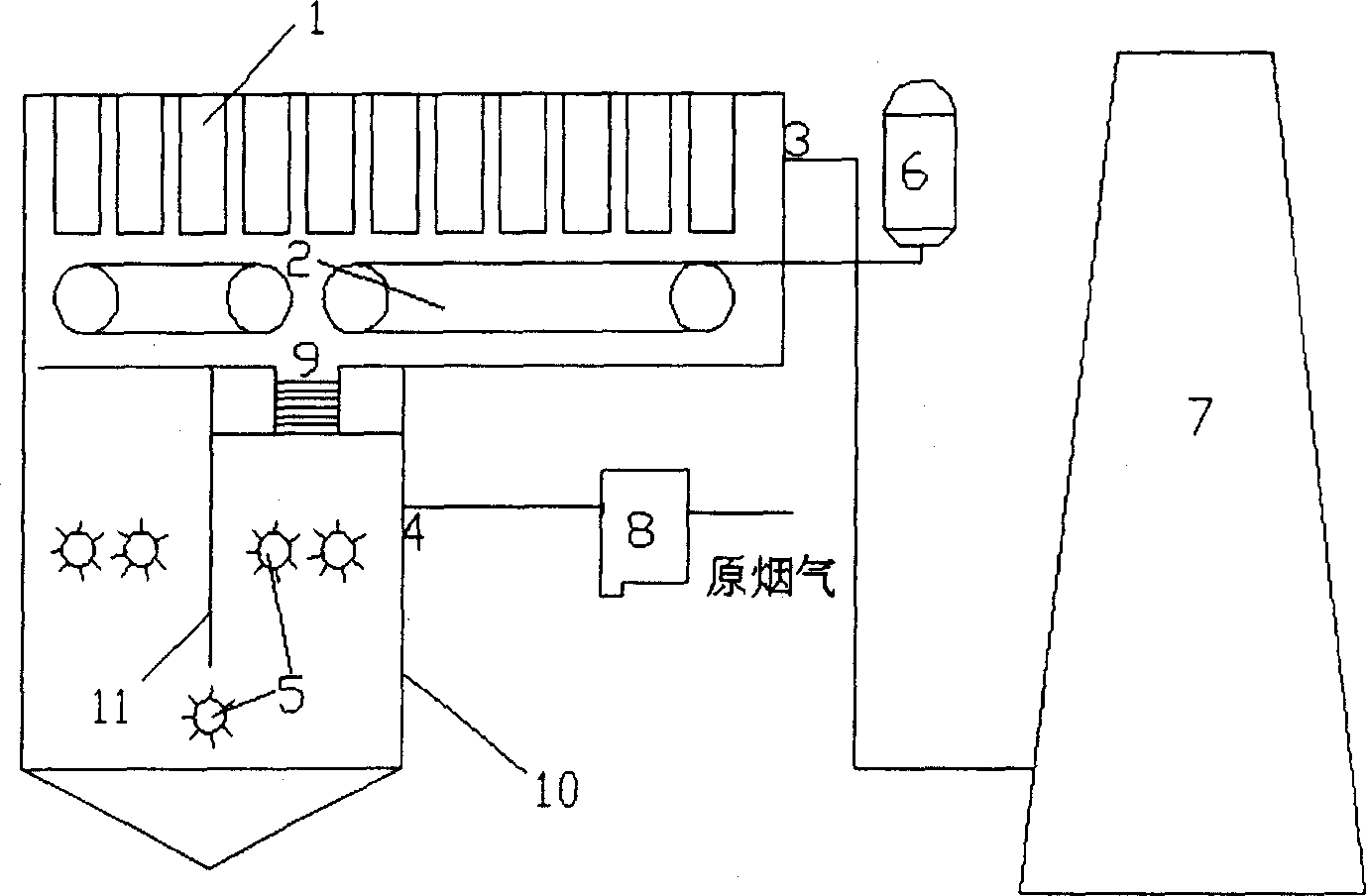

[0016] As shown in the figure, the raw flue gas produced by the boiler enters the semi-horizontal dense-phase double tower from the flue gas inlet 4 through the electrostatic precipitator 8, and is continuously added to the material seal layer 9 from the raw material bin 6 under the action of the agitator. The falling activated calcium-based absorbent (desulfurizer) reacts. Here, the function of the material sealing layer 9 is to enable the desulfurizer continuously added from the raw material bin 6 to fall from top to bottom to react with the flue gas, and at the same time prevent the flue gas entering the dry tower from penetrating upward through the material sealing layer to enter the top and bottom of the tower. The flue gas after the reaction is mixed. The flue gas undergoes desulfurization reaction while being stirred by the agitator on one side of the tower. When it reaches the bottom of the tower from top to bottom, it is mass-transferred by the agitator 5 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com