Preparation method of composite acids doped with conductive polyaniline

A technology of conductive polyaniline and compound acid, which is applied in the field of compound acid doping to prepare conductive polyaniline, which can solve the problems of high cost and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

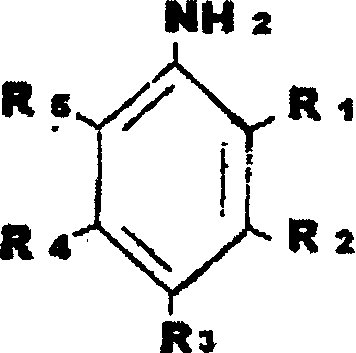

Method used

Image

Examples

Embodiment 1

[0034] Weigh 8g of sulfosalicylic acid into 100ml of distilled water in a beaker, and stir until completely dissolved. Pour the solution into a 250ml three-necked bottle, slowly add 2g of aniline dropwise, and stir at high speed. After stirring for 30 minutes, add the prepared ammonium peroxide solution dropwise for 30 minutes. React for ten hours at 15°C, filter with suction, put the polyaniline filter cake in an oven, bake at about 50°C for 24 hours, and grind it into powder. The conductivity of the polyaniline powder was measured by a four-electrode conductivity meter to be 11 S / cm.

Embodiment 2

[0036] Keeping the mass ratio of dopant to aniline monomer unchanged, changing the dopant component to be co-doped with sulfosalicylic acid and sodium dodecylbenzenesulfonate, changing the concentration of sulfosalicylic acid in the composite dopant Middle component is 87.5%, and other conditions are identical with embodiment 1. The electrical conductivity of the polyaniline powder was measured to be 8.3 S / cm.

Embodiment 3

[0038] Weigh 5.6g of sulfosalicylic acid and 2.4g of sodium dodecylbenzenesulfonate into 100ml of distilled water with a beaker, and stir until completely dissolved. Pour the solution into a 250ml three-necked bottle, slowly add 2g of aniline dropwise, and stir at high speed. After 30 minutes, the n-butanol solution was slowly added dropwise until the whole emulsion system became transparent. Then add the prepared ammonium peroxide solution dropwise for 30 minutes. React for ten hours at 15°C, filter with suction, put the polyaniline filter cake in an oven, bake at about 50°C for 24 hours, and grind it into powder. The electrical conductivity of the polyaniline powder was measured to be 5.8 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com