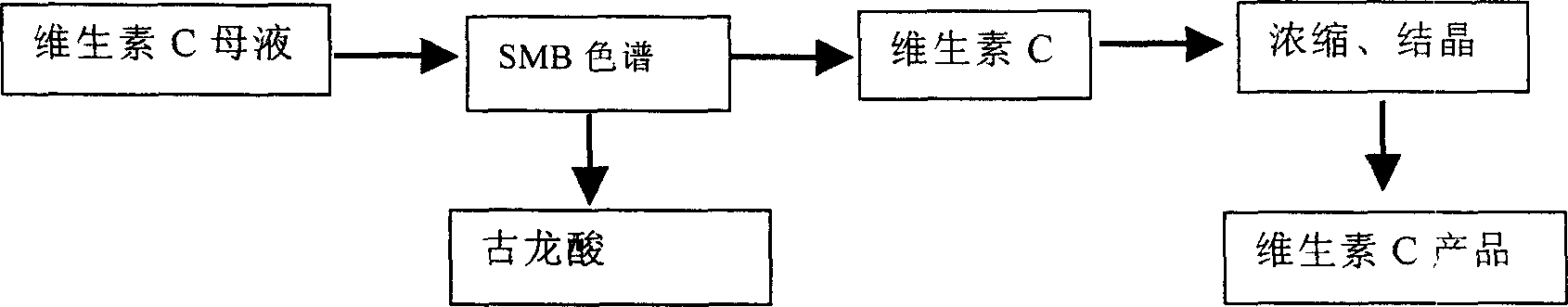

Method for extracting Vitamin C and gulonic acid from Vitamin C mother liquor

A vitamin and coronic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of three-waste pollution, inability to recrystallize, etc., and achieve the effects of high resin utilization, low production cost, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation method of the resin of the present invention, the reaction conditions of the suspension polymerization may be well-known suspension reaction conditions in the art. In a preferred example of the present invention, the reaction temperature of the suspension reaction is 60-110°C, preferably 75-90°C, the pressure is normal pressure, and the reaction time is 4-10 hours, preferably 6 to 7 hours.

[0034] 2. Acidic cationic functionalization of resin matrix

[0035] The gel or macroporous reticular cross-linked interpolymer containing acrylic acid group and / or methacrylic acid group synthesized by the present invention can be obtained by hydrolysis only due to its own acidic functional group. Suitable type of weakly acidic cationic resin.

[0036] The gel or macroporous network cross-linked interpolymer containing acrylate groups and / or methacrylate groups synthesized by the present invention needs to be hydrolyzed by a NaOH solution with a concentration o...

Embodiment

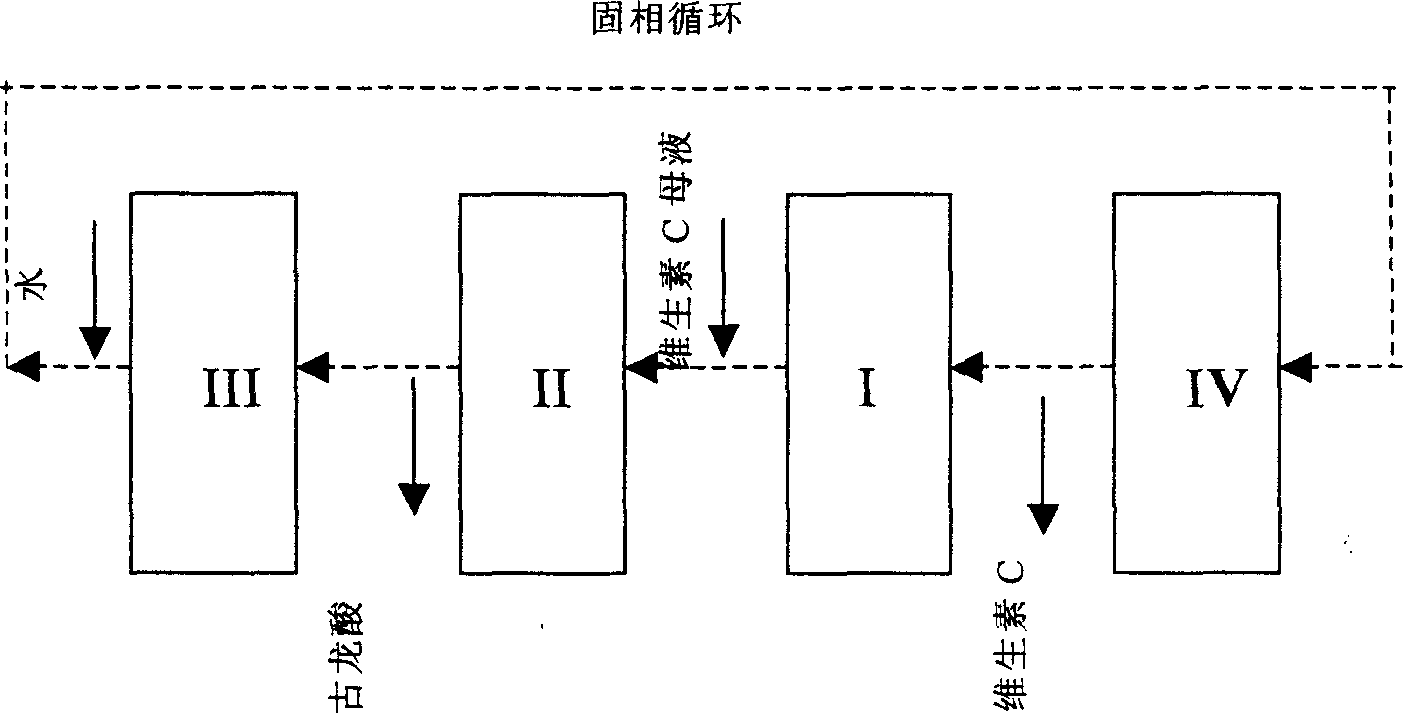

[0052] In the simulated moving bed operating system composed of eight 40mm×1200mm chromatographic columns connected in series, the macroporous acidic cationic resin synthesized by 30% styrene monomer and 70% methacrylate-based monomer is filled. The liquid is vitamin C mother liquor, wherein the concentration of vitamin C is about 18.5%, and the concentration of gulong acid is about 39%. The mother liquor is passed through a simulated moving bed. The operating conditions of the simulated moving bed are as follows: separation temperature 75°C, system pressure 1.1Mpa, feed The feed rate is 1L / h, the elution water feed rate is 3.5L / h, and the feed reaches equilibrium after 24 hours. The output obtained is as follows:

[0053] 1) Vitamin C part: the concentration of vitamin C is about 12.7%, the purity of vitamin C is 94.8%, and the concentration of gulong acid is 4.6% (the volume is 1.5 times of the mother liquor of vitamin C fed).

[0054] 2) Gulonic acid concentration: the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com