Equipment and technique for producing micro seam acoustic board

A technology of production equipment and production process, applied in the field of production equipment and process of micro-slit sound-absorbing panels, can solve problems such as difficult large-scale industrial production, selection limitation of plate properties, difficulty in processing and production, etc., and achieves high production efficiency and processing. The process is stable and reliable, and the sound absorption effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The production equipment and process of the micro-slit sound-absorbing panel of the present invention will be further described in detail below in conjunction with the accompanying drawings.

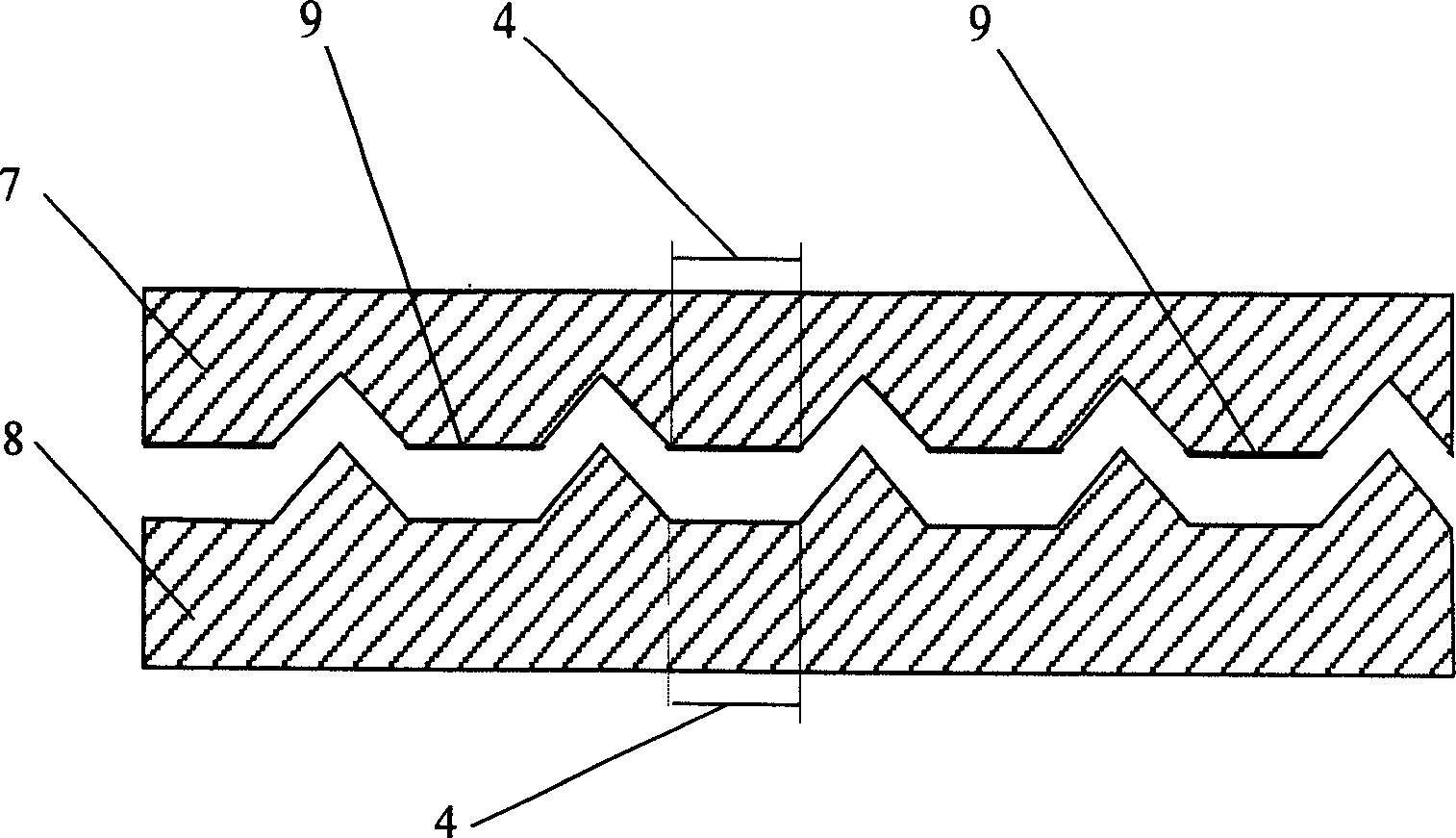

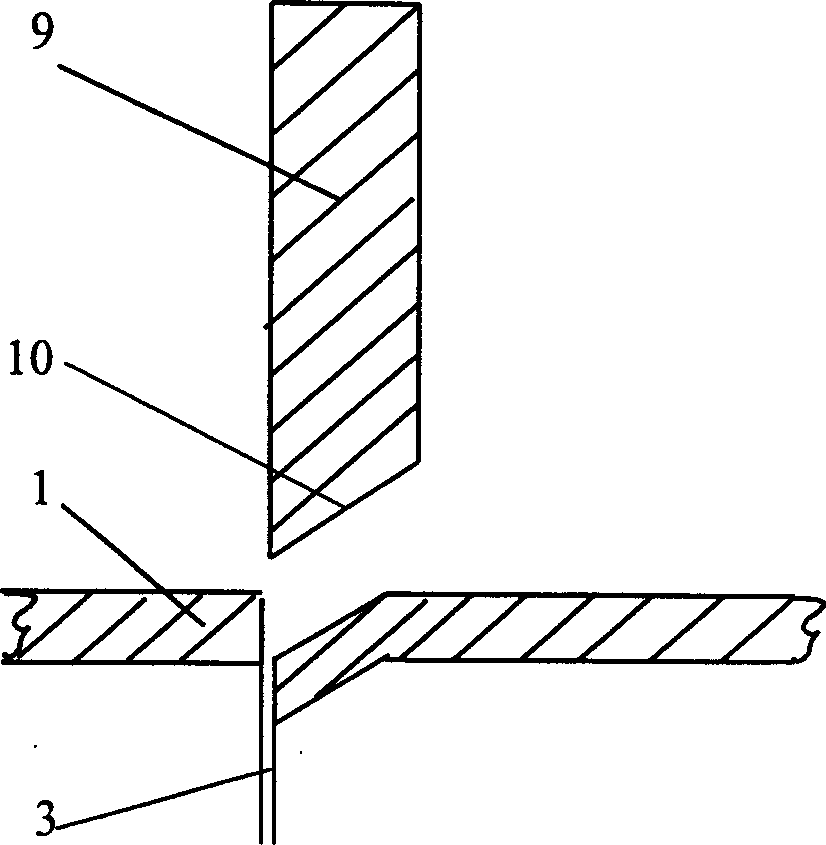

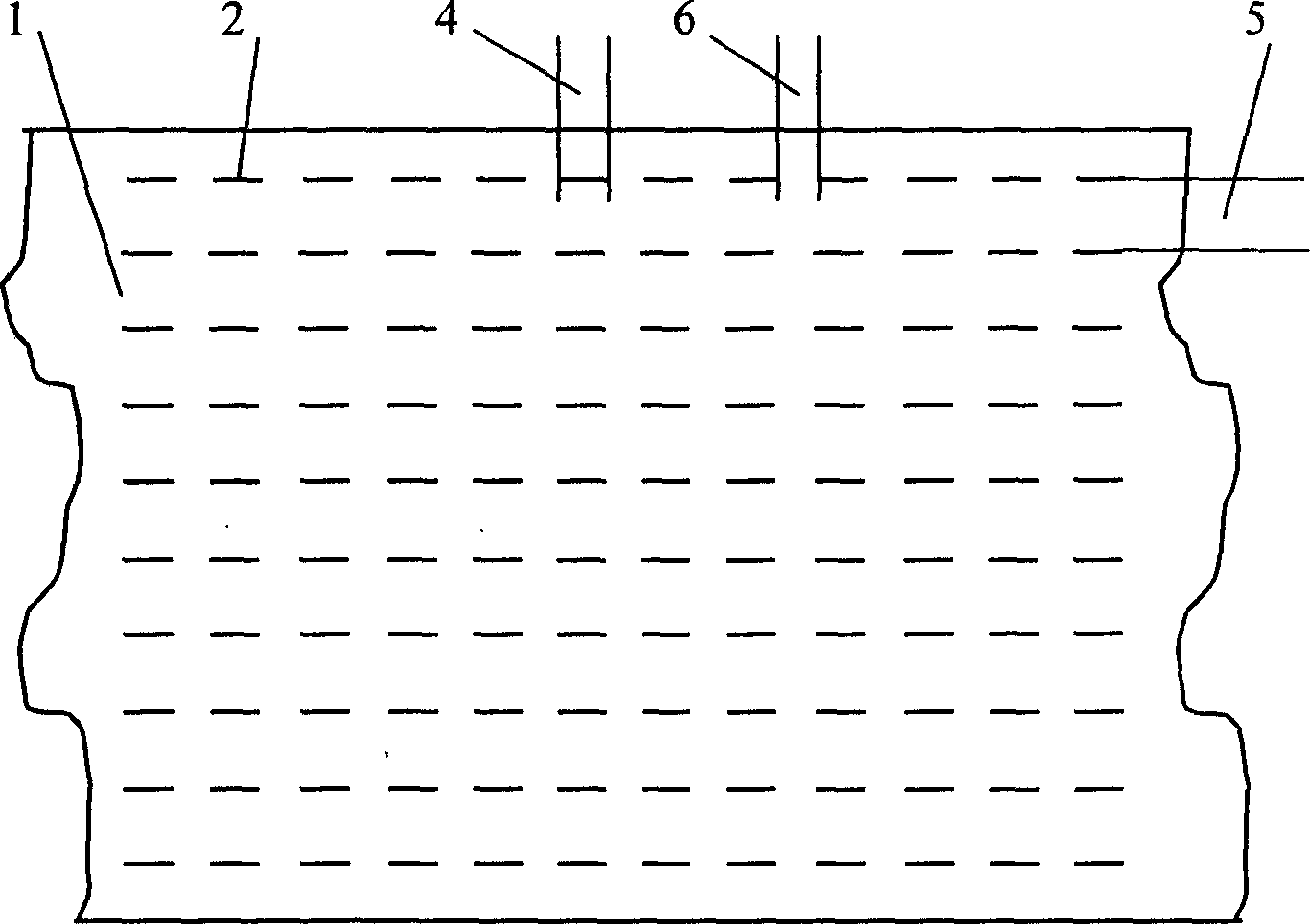

[0026] Such as Figure 1 to Figure 4 As shown, the micro-slit sound-absorbing panel production equipment of the present invention includes a power system connected to each other, a precision stamping system, a parameter determination system and an explanatory detection instrument. In the precision stamping system, the rotary arm of the punch press controls the punch 7 of the stamping mold to move up and down , the punch 7 is provided with a plurality of punches 9, the more the number of the punches 9, the more the number of gaps 2 processed in a specified time, the higher the production efficiency; the end of the punch 10 It is a slope structure; the precision stamping system adopts an automatic stepping form; the parameter detection instrument is an optical projection measuring i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com