Casting dies for engine cam shaft

A technology for casting molds and camshafts, used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problem that the metallographic structure and mechanical and physical properties of castings cannot be effectively guaranteed, the rejection rate is high, and the molding is difficult. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

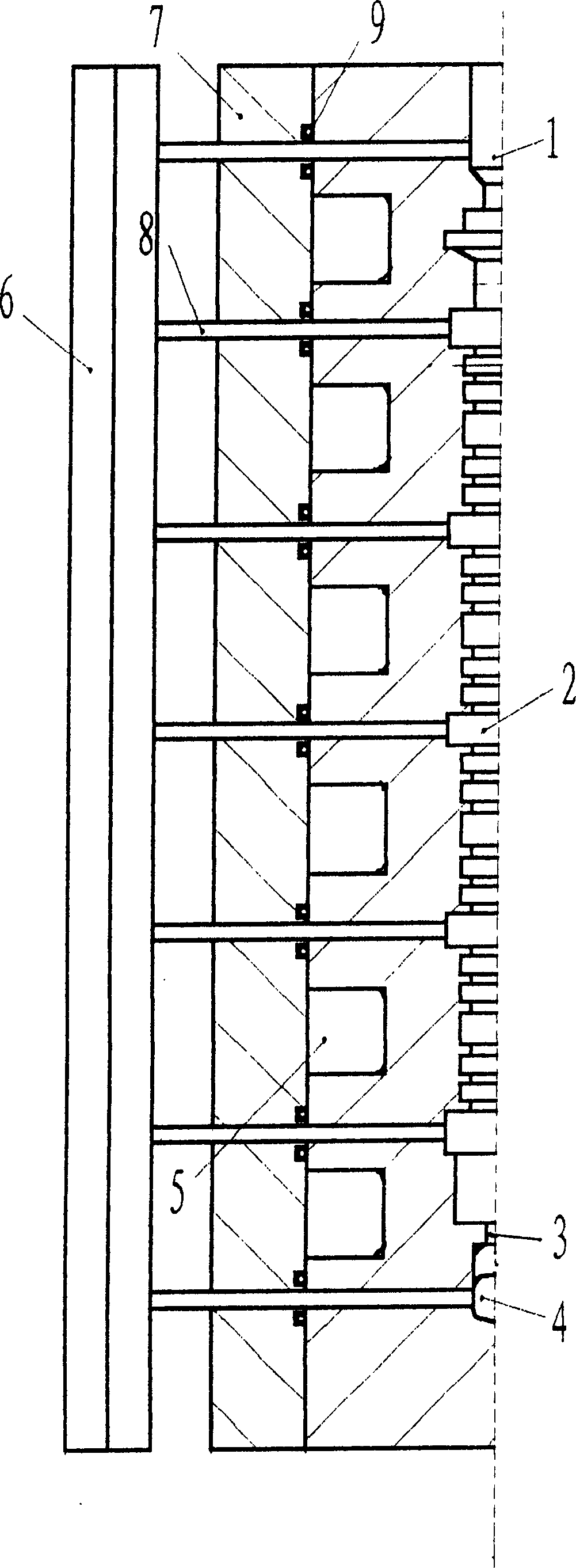

[0010] The casting mold of a kind of engine camshaft of the present invention is that the sand mold is replaced by a metal mold, and the camshaft is integrally cast; the material of said metal mold is a chrome-copper alloy, and wherein the composition of copper accounts for 93% of the total weight; the mold includes The cavity 2 surrounded by the mold body and the workpiece ejection mechanism have a runner 4 connected to the gate at the bottom, an inrunner 3 in the middle and a feeding riser 1 at the top in the cavity; The ejector mechanism consists of a top plate 6 and an ejector rod 8 fixed thereon, the ejector rod and the workpiece in the cavity can be connected in contact; there is a backing plate 7 between the mold body and the top plate, and a backing plate and a mold body There is a sealing ring 9, and a water cooling channel 5 is provided on the mold body. Using the high thermal conductivity of copper alloy, the heat is quickly taken away through the cooling system, so ...

Embodiment 2

[0012] In embodiment 1, the mold material is changed to nickel-copper alloy, and the copper component accounts for more than 80% of the total weight; the rest repeat embodiment 1.

Embodiment 3

[0014] In embodiment 1, the mold material is changed to tungsten-copper alloy, and the copper component accounts for more than 78% of the total weight; the rest repeat embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com