Heat-resistance protective tube and its mfg. method

A manufacturing method and heat-resistant technology, which can be applied to thermometers that are directly sensitive to heat, measuring heat, thermometer parts, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

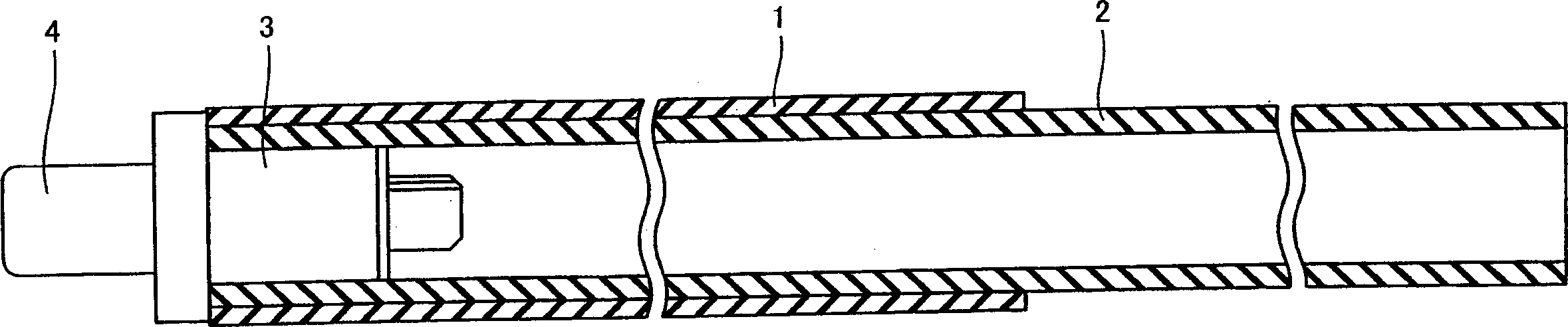

Image

Examples

Embodiment 1

[0041] Add 2% by weight of aluminum oxide as a secondary component of heat-resistant inorganic powder and 2% by weight of glass fiber as inorganic fiber to diatomite with an average particle size of 13.4 μm and heat-treated at a temperature above 1000°C to form an inorganic mixed powder , adding as additives to the inorganic mixed powder, an organic dispersant sodium polycarboxylate aqueous solution, an organic binder carboxymethyl cellulose, and an inorganic binder silica gel at a solid content conversion of 10% by weight. Then, ion-exchanged water corresponding to 10% by weight or 70% by weight of the solid content was added thereto, stirred with a kneader, and mixed to obtain a clay-like molding material. Put the obtained molding material into a vacuum extrusion molding machine cooled to 0°C to 10°C.

[0042]The vacuum extrusion molding machine used in Example 1 has a head at the front end of the drum. A paper tube is inserted into the space part provided at the center of ...

Embodiment 2

[0045] Containing 83.5% by weight of diatomite heat-treated at a temperature above 700°C with an average particle size of 18.6 μm, 8.5% by weight of olivine sand with an average particle size of 40-50 μm, and 5% by weight of glass fibers as inorganic fibers. In the thermal inorganic powder, add inorganic dispersant sodium hexametaphosphate, organic binder, 3% by weight (corresponding to the ratio of diatomaceous earth, olivine sand and glass fiber total amount) in terms of solid content as additives. Agent carboxymethyl cellulose, inorganic binder sodium silicate, and then add ion-exchanged water corresponding to 3% by weight of solid content equivalent to 50% by weight, stir with a kneader, and mix to make a clay-like molding material. Put the obtained molding material into a vacuum extrusion molding machine cooled to 0°C to 10°C.

[0046] In Example 2, the same vacuum extrusion molding machine having a head as in Example 1 above was used. A paper tube was inserted into the...

Embodiment 3

[0048] Containing 46.5% by weight of diatomite with an average particle size of 18.6 μm that has been heat-treated at a temperature above 700°C, 18.5% by weight of wollastonite with an average particle size of 17.6 μm and an aspect ratio of 10 to 20, and 28% by weight of average particle size In the heat-resistant inorganic powder of olivine sand with a diameter of 40 to 50 μm, an organic compound of 7% by weight (corresponding to the total amount of diatomaceous earth, wollastonite, and olivine sand) was added as an additive. Dispersant sodium polycarboxylate aqueous solution, organic binder polyvinyl alcohol, inorganic binder silica gel and aluminum glue, and then add ion-exchanged water corresponding to 7% by weight of solid content equivalent to 45% by weight, and stir with a kneader , mixed to make a clay-like molding material. Put the obtained molding material into a vacuum extrusion molding machine cooled to 0°C to 10°C.

[0049] This embodiment 3 uses the vacuum extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com