Process for synthesizing tin titanium carbide ceramic powder under atmospheric pressure

A ceramic powder and normal pressure synthesis technology, which is applied in the field of preparation of high-purity tin carbide titanium Ti2SnC in batches under normal pressure, can solve the problems of high purity and cost of SnC, long preparation time, expensive sintering equipment, etc., and shorten the synthesis time , Simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] According to the molar ratio of Ti:Sn:TiC=1:0.8:0.9, weigh 24.4 grams of Ti powder, 48.4 grams of Sn powder, and 27.2 grams of TiC powder, put them into a plastic bottle, use agate balls as the grinding medium, and grind them on a ball mill Dry mix for 5 hours. Then in the mould, it is pressed into a block under a pressure of 50MPa, put into a high-temperature furnace, and in a vacuum atmosphere, the temperature of the furnace is raised to 1150°C at a heating rate of 20°C / min, and the holding time is 30 minutes, that is, the high-purity Ti 2 SnC powder.

Embodiment approach 2

[0022] According to the molar ratio of Ti:Sn:TiC=1:0.7:0.8, weigh 26.8 grams of Ti powder, 46.5 grams of Sn powder, and 26.7 grams of TiC powder, and dry-mix them on a ball mill for 5 hours with agate balls as grinding media. Then in the mould, the pressure of 20MPa is pressed into a block, put into a high-temperature furnace, vacuum atmosphere, the temperature of the furnace is raised to 1150°C at a heating rate of 10°C / min, and the holding time is 15 minutes, that is, the high-purity Ti 2 SnC powder.

Embodiment approach 3

[0024] According to the molar ratio of Ti:Sn:TiC=1:0.8:0.9, weigh 24.4 grams of Ti powder, 48.4 grams of Sn powder, and 27.2 grams of TiC powder, and dry mix them on a ball mill for 5 hours with agate balls as grinding media. Then in the mould, press the pressure of 20MPa into a block, put it into a high-temperature furnace, vacuum atmosphere, raise the temperature of the furnace to 1200°C at a heating rate of 15°C / min, and hold the temperature for 15 minutes to obtain high-purity Ti 2 SnC powder.

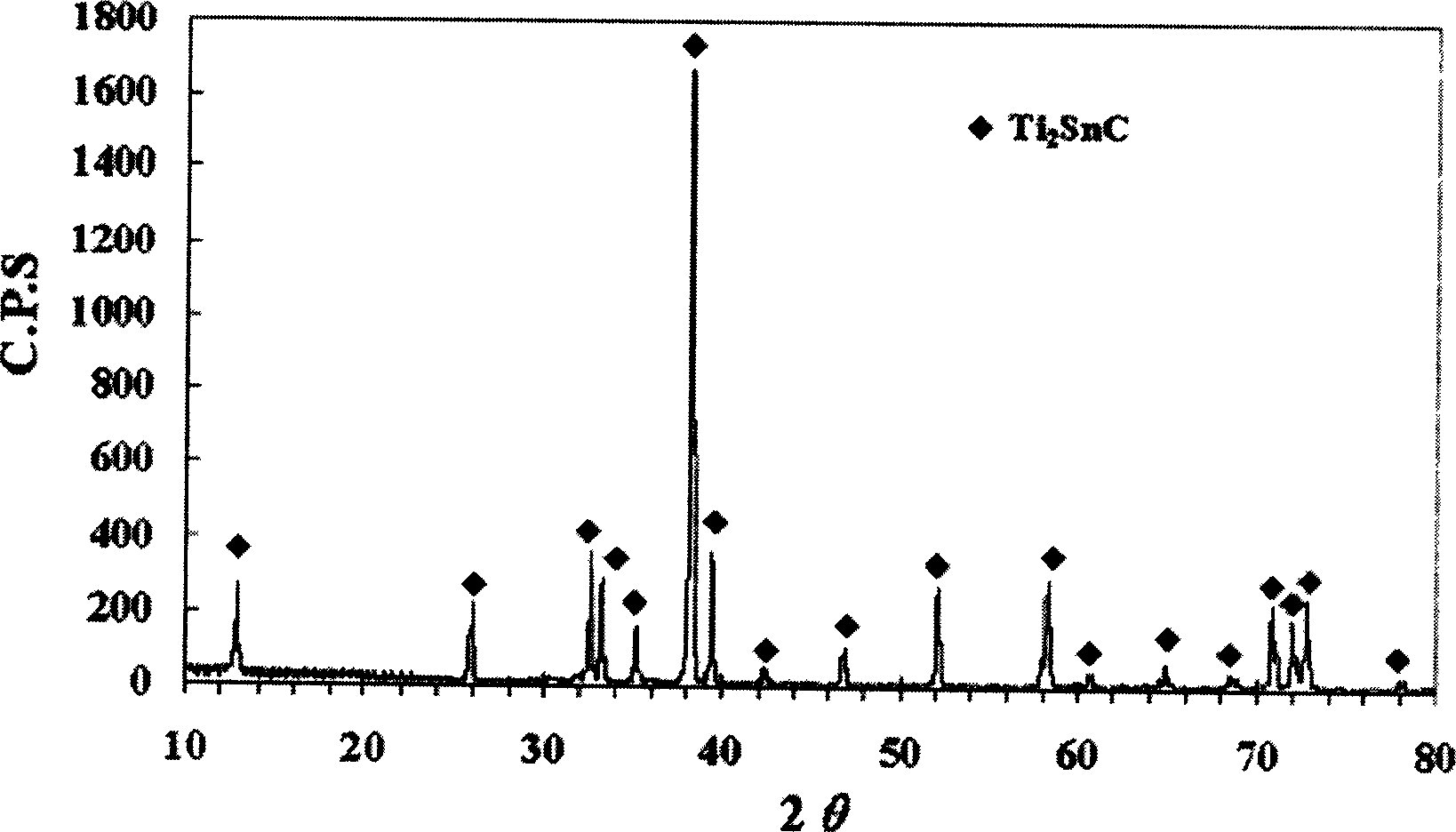

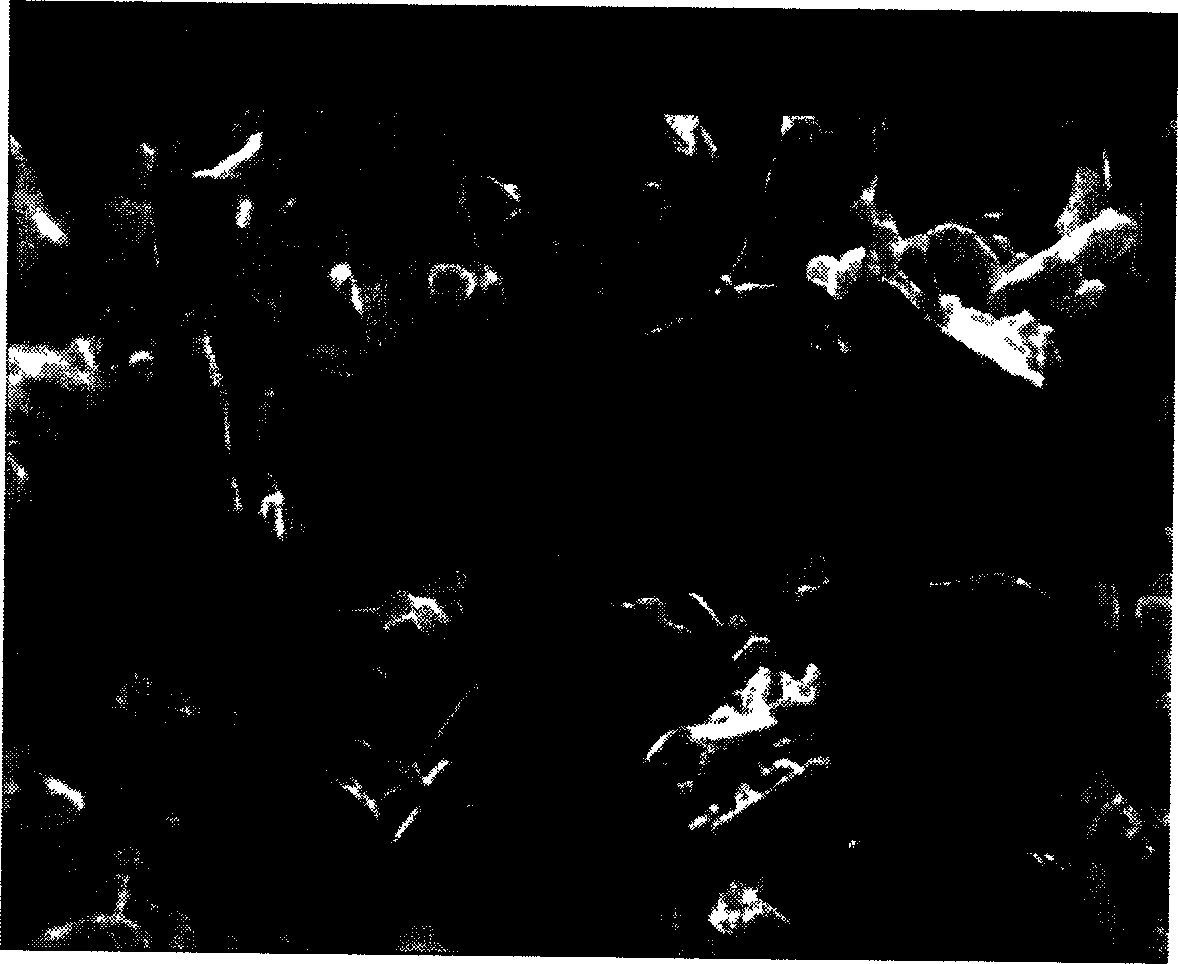

[0025] Prepared Ti 2 The XRD pattern of SnC powder is attached figure 1 . It can be seen from the figure that the product has high purity, and there is no impurity phase such as TiC in the XRD spectrum. Ti 2 SnC powder morphology see attached figure 2 . It can be seen from the figure that the particles are flaky crystals with a particle size of less than 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com