Method for producing light-weight hard fibre board

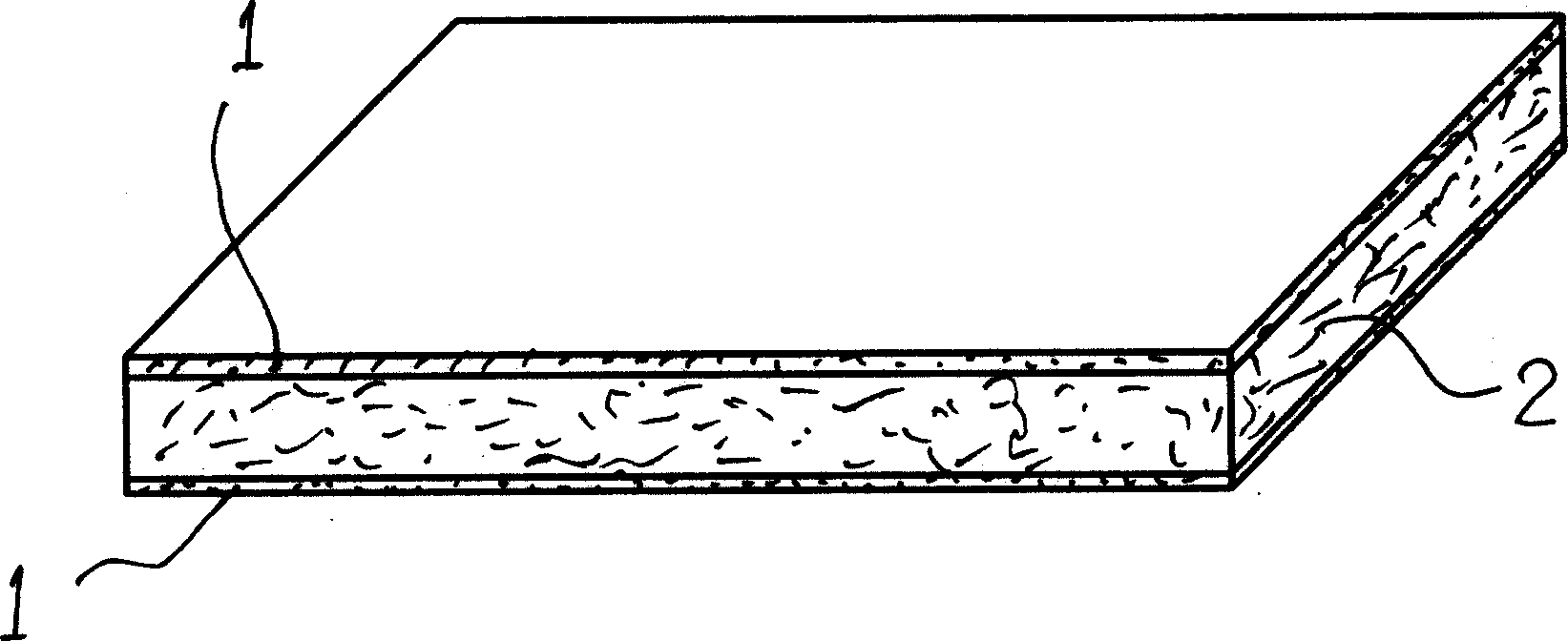

A technology of hard fiber board and production method, applied in the field of fiber board, can solve the problems of rough texture surface, heavy weight, use restrictions, etc., and achieve the effect of smooth on both sides and firm texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step: chipping, the wood is cut into thin wood chips of 18×15×5 mm with a chipper, and the debris is screened out with a sieve;

[0030] The second step: cleaning, cleaning the veneer with water;

[0031] The third step: steaming, steaming the cleaned veneer with high-temperature steam at 120°C for 6 minutes;

[0032] The 3rd step: heat grinding, grind the veneer after cleaning into 15 mesh fiber bundles and account for 60% wood fiber with double grinder;

[0033] The fourth step: glue spraying, evenly spraying 100Kg urea-formaldehyde resin glue in the proportion of the designed fiberboard per cubic meter in the ground fiber;

[0034] Step 5: Pipeline drying, drying the fiber bundles after glue spraying with hot air to reduce the water content to 9%;

[0035] The sixth step: laying, laying the dried fiber bundles in the forming chamber to a thickness of 230 mm;

[0036] Step 7: Pre-press, reduce the thickness to 115mm after pre-pressing by the pre-pressing ...

Embodiment 2

[0040] The first step: chipping, the wood is cut into thin wood chips of 19×16×2 mm with a chipper, and the debris is screened out with a sieve;

[0041] The second step: cleaning, cleaning the veneer with water;

[0042] The third step: steaming, steaming the cleaned veneer with high-temperature steam at 125°C for 4 minutes;

[0043] The 3rd step: heat grinding, grind the veneer after cleaning into 16 mesh fiber bundles and account for 50% wood fiber with double grinder;

[0044] The fourth step: glue spraying, evenly spraying 115Kg of urea-formaldehyde resin glue in the proportion of the designed fiberboard per cubic meter in the ground fiber;

[0045] Step 5: Pipeline drying, dry the fiber bundles after glue spraying with hot air to reduce the water content to 10%;

[0046] The sixth step: laying, laying the dried fiber bundles in the forming chamber to a thickness of 230 mm;

[0047] The seventh step: pre-pressing, the thickness is reduced to 92mm after pre-pressing by ...

Embodiment 3

[0051] The first step: chipping, the wood is cut into thin wood chips of 20×16×3 mm with a chipper, and the debris is screened out with a sieve;

[0052] The second step: cleaning, cleaning the veneer with water;

[0053] The third step: steaming, steaming the cleaned veneer with high-temperature steam at 130°C for 3 minutes;

[0054] The third step: heat grinding, use double grinder to grind the cleaned wood chips into wood fibers with 17 mesh fibers accounting for 70%;

[0055] The fourth step: glue spraying, evenly spraying glue in the ratio of 120Kg731 type water-soluble resin in the ratio of designed per cubic meter of fiberboard in the ground fiber;

[0056] Step 5: Pipeline drying, drying the glued fibers with hot air to reduce the water content to 11%;

[0057] The sixth step: laying, laying the dried fibers in the forming room to a thickness of 230 mm;

[0058] The seventh step: pre-pressing, the thickness is reduced to 138mm after pre-pressing by the pre-pressing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com