Corrosion and scale inhibition sterilizing agent for circulating cooling water under high concentration multiple

A technology for circulating cooling water, scale and corrosion inhibition, applied in the field of chemistry, can solve problems such as production accidents, product quality decline, and influence system heat exchange effect, etc., to achieve high synergy, reduce operating costs, and reduce the effect of pretreatment processes.

Inactive Publication Date: 2016-06-15

JIANGSU SENSE WATER CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CaCO 3 The heat conduction system of scale is only about 1 / 100 of that of steel. Once scale is formed on the surface of the heat exchanger, it will seriously affect the heat exchange effect of the system, resulting in a decline in product quality and serious production accidents.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

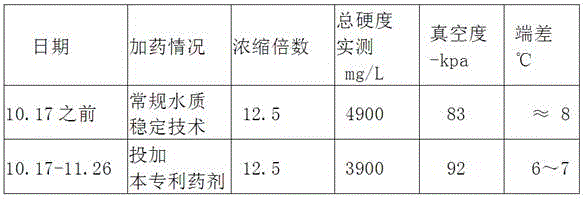

[0021] As shown in Table 1, by weight percentage, 15 parts of basic oxide, 35 parts of silicate, 40 parts of borate, 5 parts of molybdate and 5 parts of metal oxide are mixed to obtain Scale and corrosion inhibitors for down-circulating cooling water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a scale-inhibiting, corrosion-inhibiting and fungicide for circulating cooling water under high concentration ratio, wherein the weight percentage of each component is: 5-15% of alkaline oxide, 30-40% of silicate, boric acid Salt 30-40%, molybdate 0-10% and metal oxide 5-10%.

Description

technical field [0001] The invention relates to water treatment technology in the chemical field, in particular to a scale and corrosion inhibitor and fungicide for circulating cooling water under high concentration ratio. Background technique [0002] As the country and society attach importance to environmental protection, the effective management and efficient use of water resources has become particularly important for industrial enterprises. In urban water supply, industrial enterprises account for 50-80% of water consumption, while 80% of industrial water is used for circulating cooling water. In order to respond to the call for energy saving and emission reduction, industrial enterprises often reduce the supplementary water volume of the circulating water system in actual production, so as to control the industrial fresh water consumption of the whole plant. However, the reduction in water replenishment means that the concentration ratio of circulating cooling wate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F5/08C02F1/50A01N59/06A01N59/00A01N59/14A01N59/16A01N59/20A01P1/00

CPCC02F5/08A01N59/00A01N59/06A01N59/14A01N59/16A01N59/20C02F1/50C02F2303/04C02F2303/08C02F2303/22

Inventor 杜娟辛兰尹乃诚郑俊毅

Owner JIANGSU SENSE WATER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com