Process for extracting 1-methylnaphthalene and 2-methylnaphthalene from tar

A technology of methylnaphthalene and tar, applied in organic chemistry, distillation purification/separation, etc., can solve the problems of heavy pollution, complicated equipment and operation, complicated operation, etc., and achieve the effect of simple process and easy automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

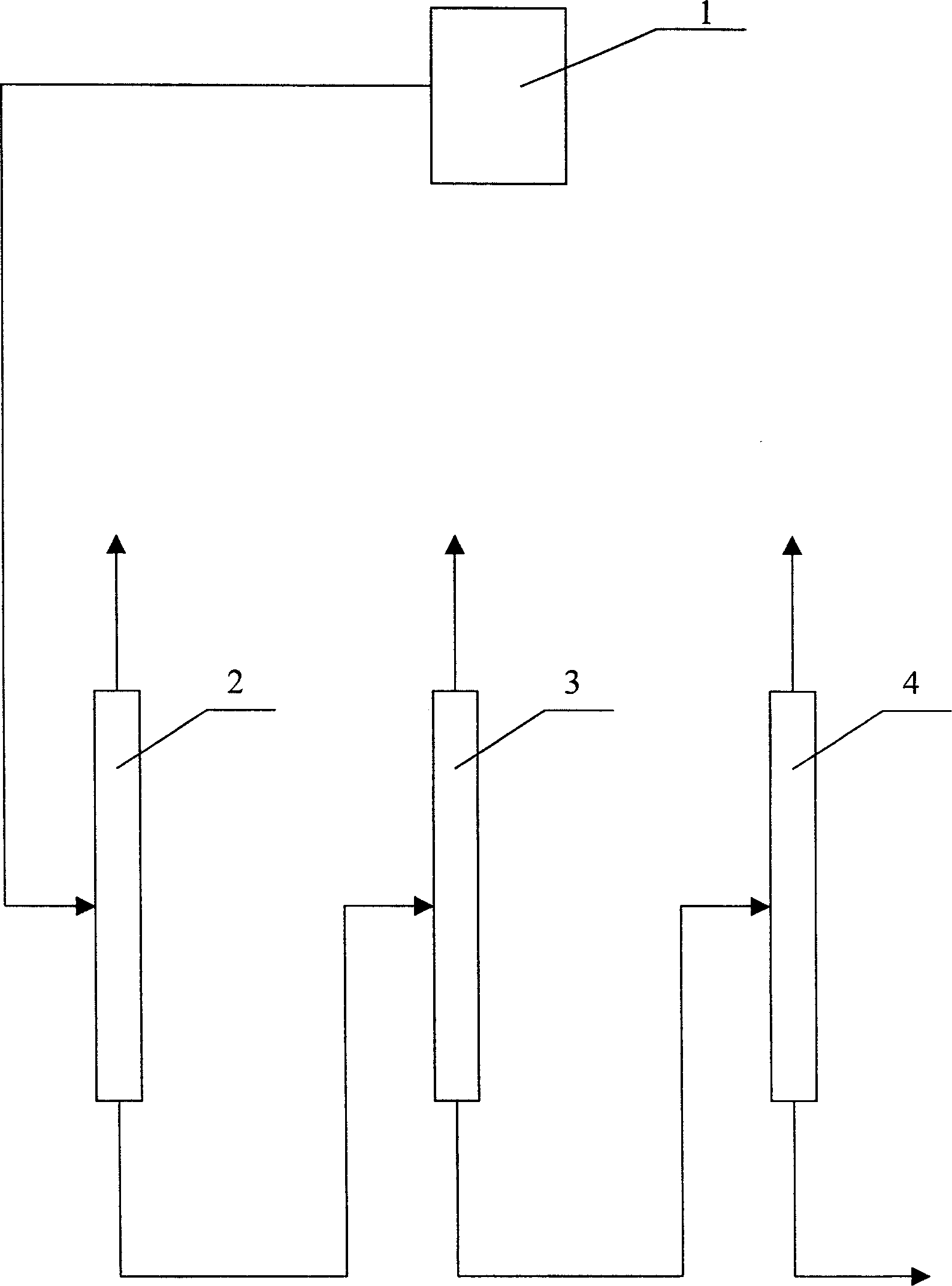

[0019] attached figure 1 Schematic diagram of the device for extracting 1-methylnaphthalene and 2-methylnaphthalene, combined with the attached figure 1 Described as follows:

[0020] Contain the coal tar washing oil of 61% of total methyl naphthalene, pump in the alkylation polymerization reactor from the raw material tank, add the solid acid SO of 6% raw material weight in the alkylation polymerization reactor 4 2- / ZrO 2 Catalyst, heat up to 75°C, feed isobutene within 1 hour, control the feed amount of isobutene to be 1% of the raw material weight, stop feeding isobutene, heat up to 100°C, continue to react for 1.5 hours, release the material, filter to remove the catalyst , the feed liquid enters the rectification tower 1, the operating pressure is 0.08 MPa, the temperature at the bottom of the tower is 233±3°C, and the temperature at the top of the tower is 195±3°C. Light components with a boiling point less than 2-methylnaphthalene are extracted from the top of the ...

Embodiment 2

[0022] combined with figure 1 Described as follows:

[0023] Containing the petroleum tar washing oil of 73% of total methyl naphthalene, pump in the alkylation polymerization reactor from the raw material tank, add the vitriol oil of raw material weight 0.5% in the alkylation polymerization reactor, be warming up to 85 ℃, at 1 Feed methyl tert-butyl ether in one hour, control the feeding amount of methyl tert-butyl ether to be 3% of raw material weight, stop feeding methyl tert-butyl ether, be warming up to 110 ℃, continue reaction 2.5 hours, Add Ca(OH) 2 Neutralize, emit material, remove sediment by filtration, feed liquid enters rectifying tower 1, extract the light component with boiling point less than 2-methylnaphthalene at the tower top of rectifying tower 1, the material at the bottom of the tower is discharged into intermediate feed tank 1, The operating pressure is 0.08MPa, the temperature at the bottom of the tower is 233±3°C, and the temperature at the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com