Internal combustion engine driving heat pump fluidized bed drying device capable of recovering used heat

A fluidized bed drying, internal combustion engine technology, applied in heating devices, heating to dry solid materials, drying solid materials, etc., can solve problems such as waste of energy, environment, pollution, etc., to reduce pollution, reduce energy consumption, and improve heat pump performance coefficients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

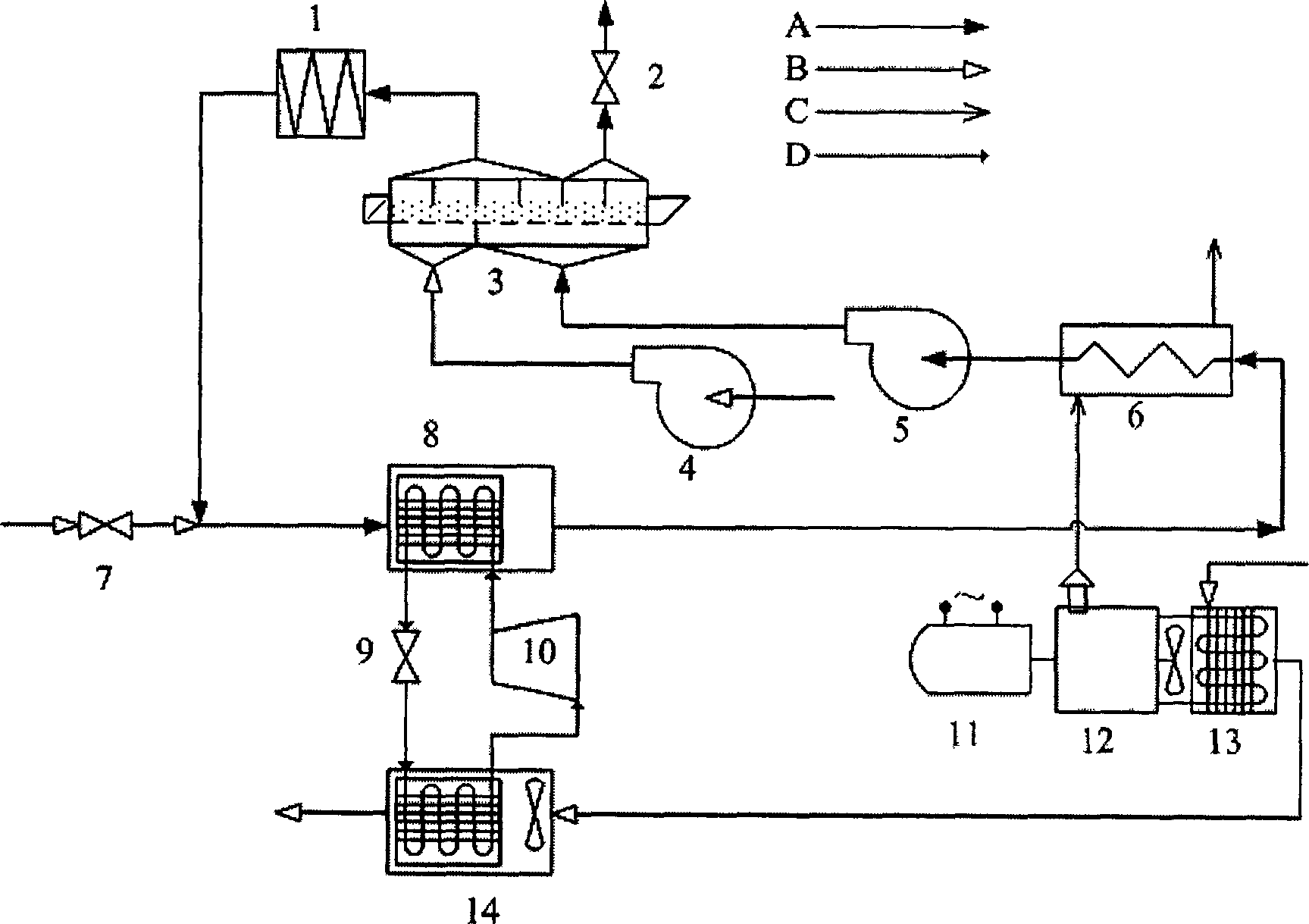

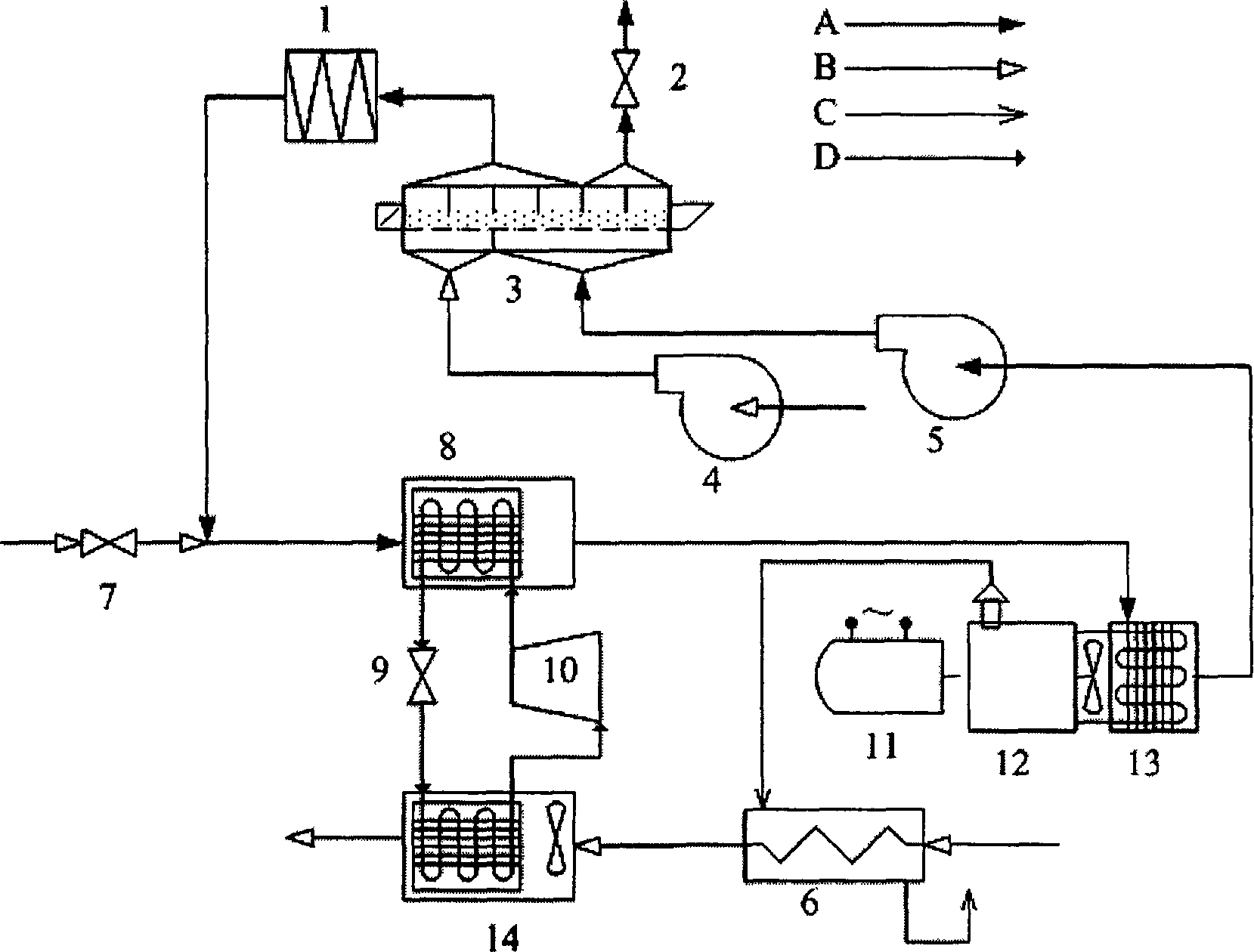

[0046] attached Figure 1-8 The drying devices shown are electric-driven modes 1 to 8, and the electric power is provided by an alternator driven by an internal combustion engine or supplied by the grid if conditions permit.

[0047] attached figure 1 The mode 1 using electric drive is shown in the figure, and the specific implementation method is: after the circulating air A is heated in the heat pump condenser 8, it is further heated in the flue gas heat exchanger 6, and enters the fluidized bed drying chamber through the circulating fan 5 3. After the ambient air B is heated in the internal combustion engine cooling water radiator 13, it releases heat in the heat pump evaporator 14, and then is discharged into the atmosphere.

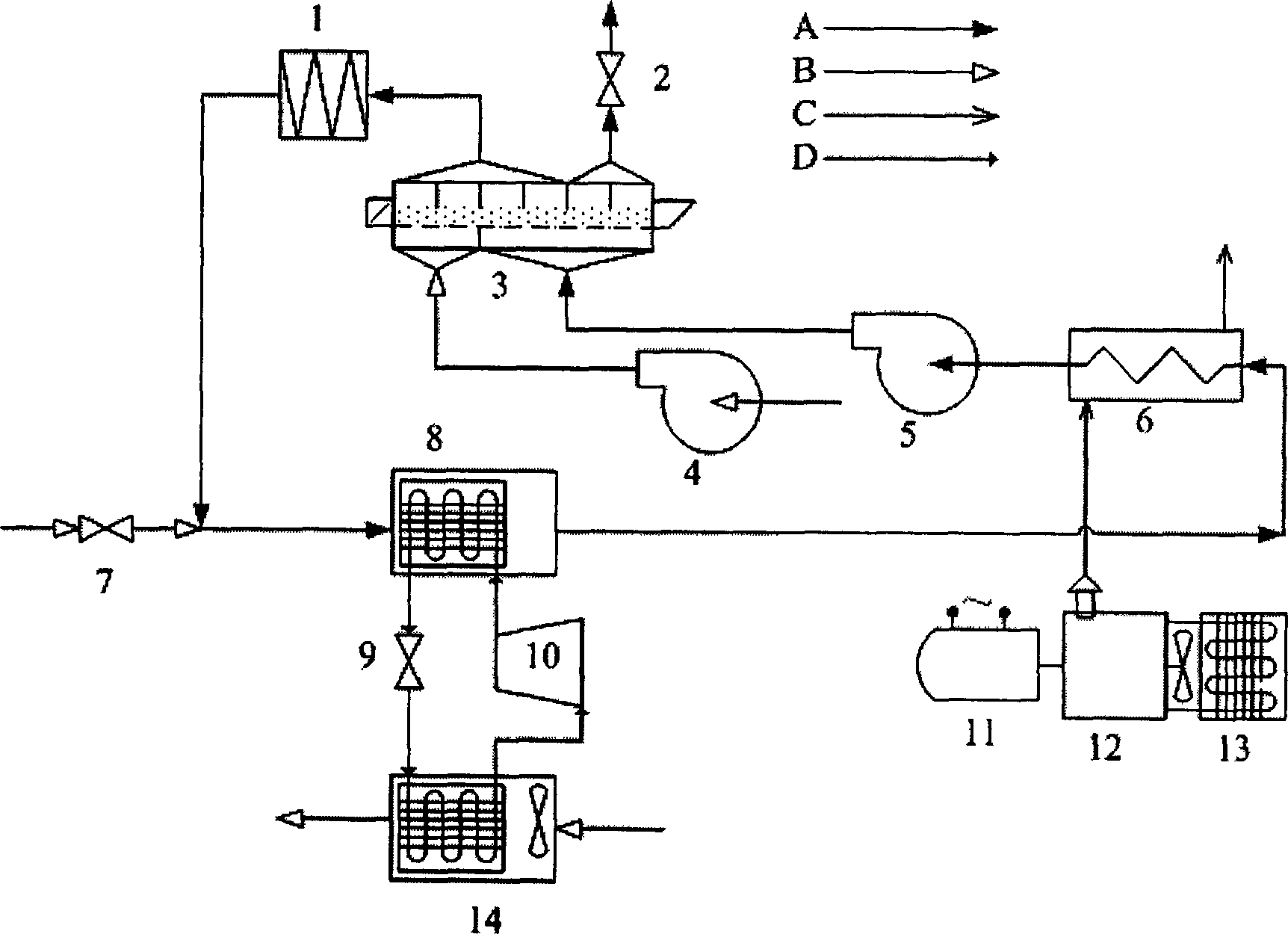

[0048] attached figure 2 The mode 2 using electric drive is shown, and the specific implementation method is: after the circulating air A is heated in the heat pump condenser 8, it is further heated in the flue gas heat exchanger 6, and enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com