Method for electroplating and grinding plate rolls before forming pore

A grinding method and microporous technology, applied in printing plate preparation, printing, etc., can solve problems such as non-grinding, and achieve the effects of improving processing capacity, shortening grinding time, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

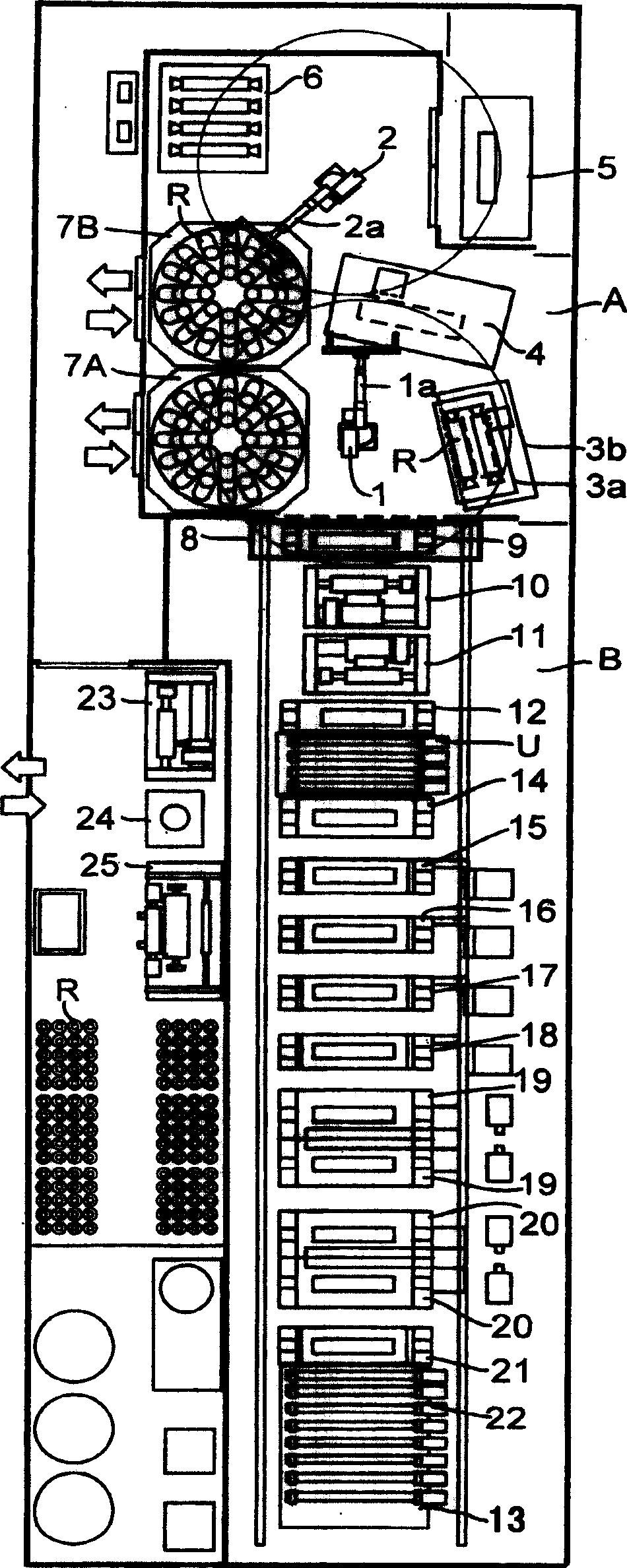

[0196] figure 1 A plan view of a plate making room that is equally applicable to all the plate making methods described above is shown.

[0197] figure 1 The shown equipment configuration shows that for a plate making company that needs various processing steps corresponding to various orders from customers, it is possible to use one production line to cope with all orders. The preferred production line equipment.

[0198] especially in figure 1 In the equipment configuration shown, the chromium plating device is not installed, and instead of it, it becomes a production line equipment that can perform nickel alloy plating, quenching, and heat dissipation and cooling.

[0199] The plate making workshop includes robot room A and electroplating room B.

[0200] On the side near the electroplating chamber B in the robot room A, an industrial robot 1 that can freely reciprocate and rotate is provided. This industrial robot 1 has a robot hand 1a that can clamp both ends of the pl...

Embodiment 2

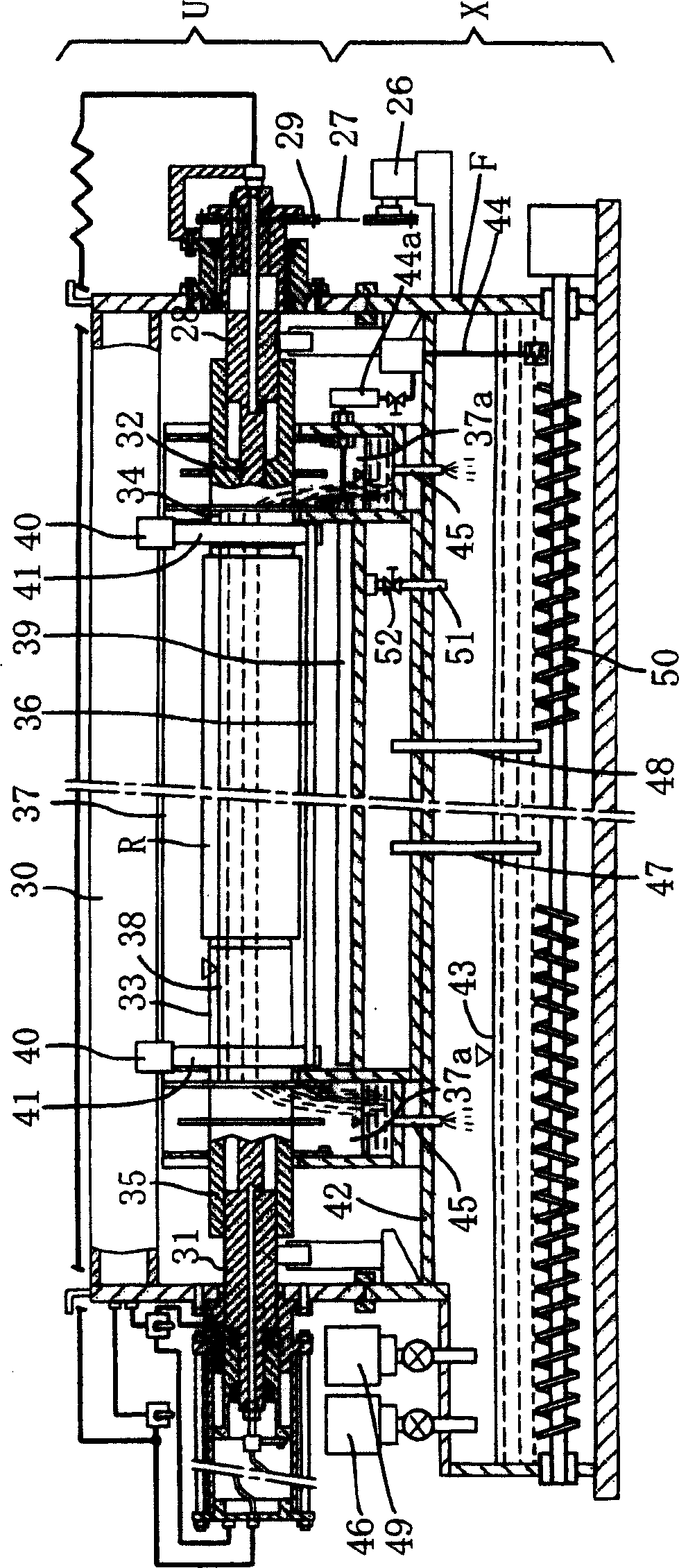

[0213] This example explains in detail an example of copper sulfate electroplating using an insoluble anode constituting a part of a plate making method with reference to the drawings.

[0214] figure 2 Shown is a copper sulfate electroplating device using an insoluble anode that is applicable to a box-shaped roller clamping and turning conveyor that is substantially the same as the box-shaped roller automatic loading and unloading device shown in Japanese Patent Publication No. 57-36995, and is mounted on the electroplating device body X Set the box-shaped roller to clamp the rotary conveying device U for copper sulfate electroplating.

[0215] It will be described in detail below. When the box-shaped rollers are placed on the electroplating apparatus main body X to clamp the rotary conveyor U, the chain 27 of the chain winding device driven by the motor 26 provided on the electroplating apparatus main body X engages the sprocket 29, and the sprocket 29 cooperates with the...

Embodiment 3

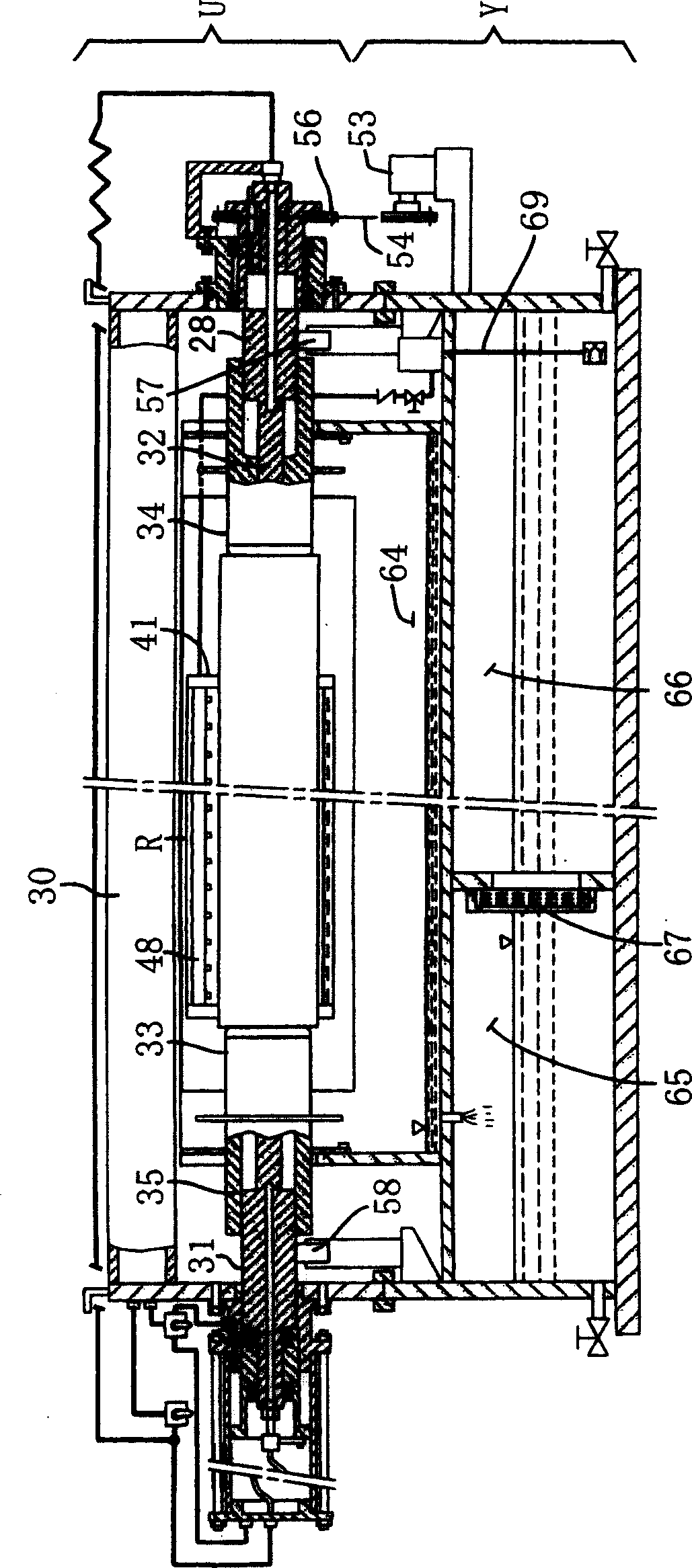

[0233] This embodiment explains in detail, with reference to the drawings, semi-finishing grinding using a liquid-impregnated abrasive-grain-fixed flexible body and mirror-finishing grinding of superfibers without fixed abrasive grains, which constitute a part of the plate making method.

[0234] image 3 A plan view showing a cylindrical polishing device for performing a cylindrical polishing method of an electrolytic polishing method with respect to a plate-making roll for gravure printing of the present invention, Figure 4 A plan view is shown, and FIG. 5 shows a longitudinal side view of main parts.

[0235] The rotary conveyor U is placed on the device body Y with the box-shaped rollers sandwiched between them, and cylindrical grinding is performed. The box-shaped roller clamping and turning conveyance device U has substantially the same configuration as the box-shaped roller automatic attachment and detachment device shown in Japanese Patent Application Publication No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com