Electromagnetic continuous casting method of composite roller and its casting equipment

A technology of composite rolls and casting equipment, applied in the field of continuous casting, can solve the problems of difficult thickness control, composite failure, large refractory materials, etc., and achieve the effect of promoting the floating of inclusions, improving surface quality, and eliminating internal shrinkage holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

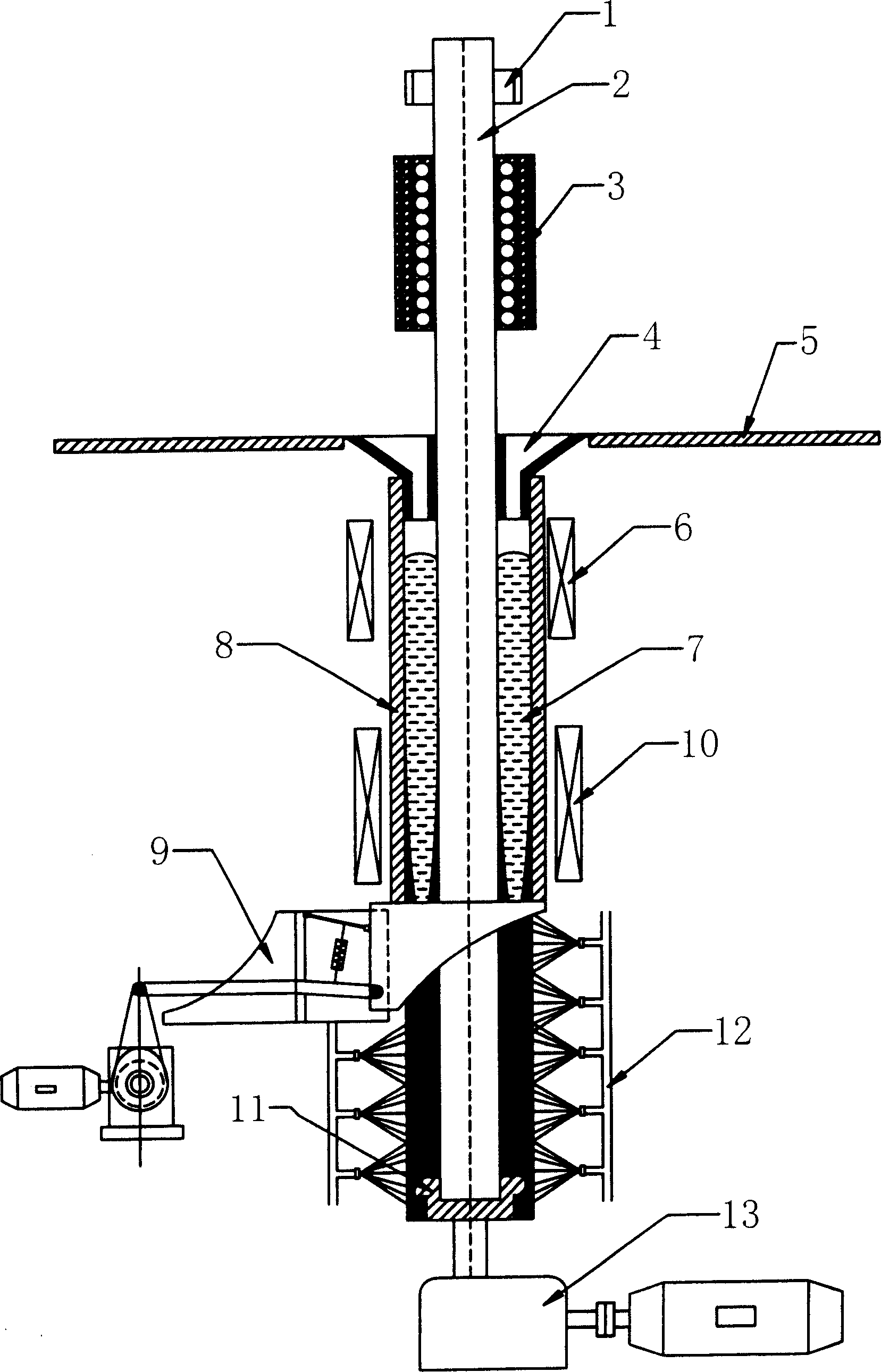

[0025]Composite roll electromagnetic continuous casting equipment and workpieces to be processed include: roll core positioning frame 1, roll core 2 (using 45# high-quality carbon structural steel bars), induction preheating furnace 3, injection flow tank 4, operating platform 5, induction Supplementary heat device 6, molten metal 7 in the working layer of the roll (its chemical composition is: C1.1%, Cr5.0%, W7.0%, Mo4.3%, V3.8%, the rest is Fe), Double electromagnetic water-cooled crystallizer 8, crystallizer vibration system 9, electromagnetic stirrer 10, positioning dummy head 11, secondary cooling system 12, billet drawing machine 13. The roller core positioning frame 1 and the induction preheating furnace 3 can move freely up and down for convenient positioning; a protective gas filling ring is installed in the induction preheating furnace 3, and the power and length of the induction preheating furnace 3 are proportional to the casting speed. matching, so that the roller...

Embodiment 2

[0027] 1. According to the requirements for the material and size of the roll core 2 in production and application, the oxide layer on the outside of the roll core 2 is removed by machining, the positioning holes are processed, and pickling is carried out to prefabricate the roll core 2 of the composite roll;

[0028] 2. Place the prefabricated roll core 2 on the central axis of the double electromagnetic water-cooled crystallizer 8, and position it by positioning the dummy head 11 and the roll core positioning frame 1;

[0029] 3. Open the cooling water valve of the double electromagnetic water-cooled crystallizer 8, then raise the positioning dummy head 11 to the lower part of the induction preheating furnace 3, switch on the power supply of the induction preheating furnace 3, and turn on the inertia protection during the preheating process Inert gas, the roller core 2 is continuously preheated during the downward movement, and it is just preheated to the preheating temperatu...

Embodiment 3

[0036] 1. According to the requirements for the material and size of the roll core 2 in production and application, the oxide layer on the outside of the roll core 2 is removed by machining, the positioning holes are processed, and pickling is carried out to prefabricate the roll core 2 of the composite roll;

[0037] 2. Place the prefabricated roll core 2 on the central axis of the double electromagnetic water-cooled crystallizer 8, and position it by positioning the dummy head 11 and the roll core positioning frame 1;

[0038] 3. Open the cooling water valve of the double electromagnetic water-cooled crystallizer 8, then raise the positioning dummy head 11 to the lower part of the induction preheating furnace 3, switch on the power supply of the induction preheating furnace 3, and turn on the protective protection during the preheating process. The gas, the roller core 2 is continuously preheated during the downward movement, and it just reaches the appropriate temperature wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com