Anti-knock energy saving engine

A technology of engine and opening and closing mechanism, which is applied in the direction of engine operation, engine components, engine control, etc., can solve the problems that the weight and volume of the engine cannot be reduced, the reactive power loss of the valve mechanism is large, and the noise of the mechanical valve mechanism is large, etc., to achieve The social benefits are considerable, the assembly process and cost are reduced, and the effect of increasing the intake and exhaust rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

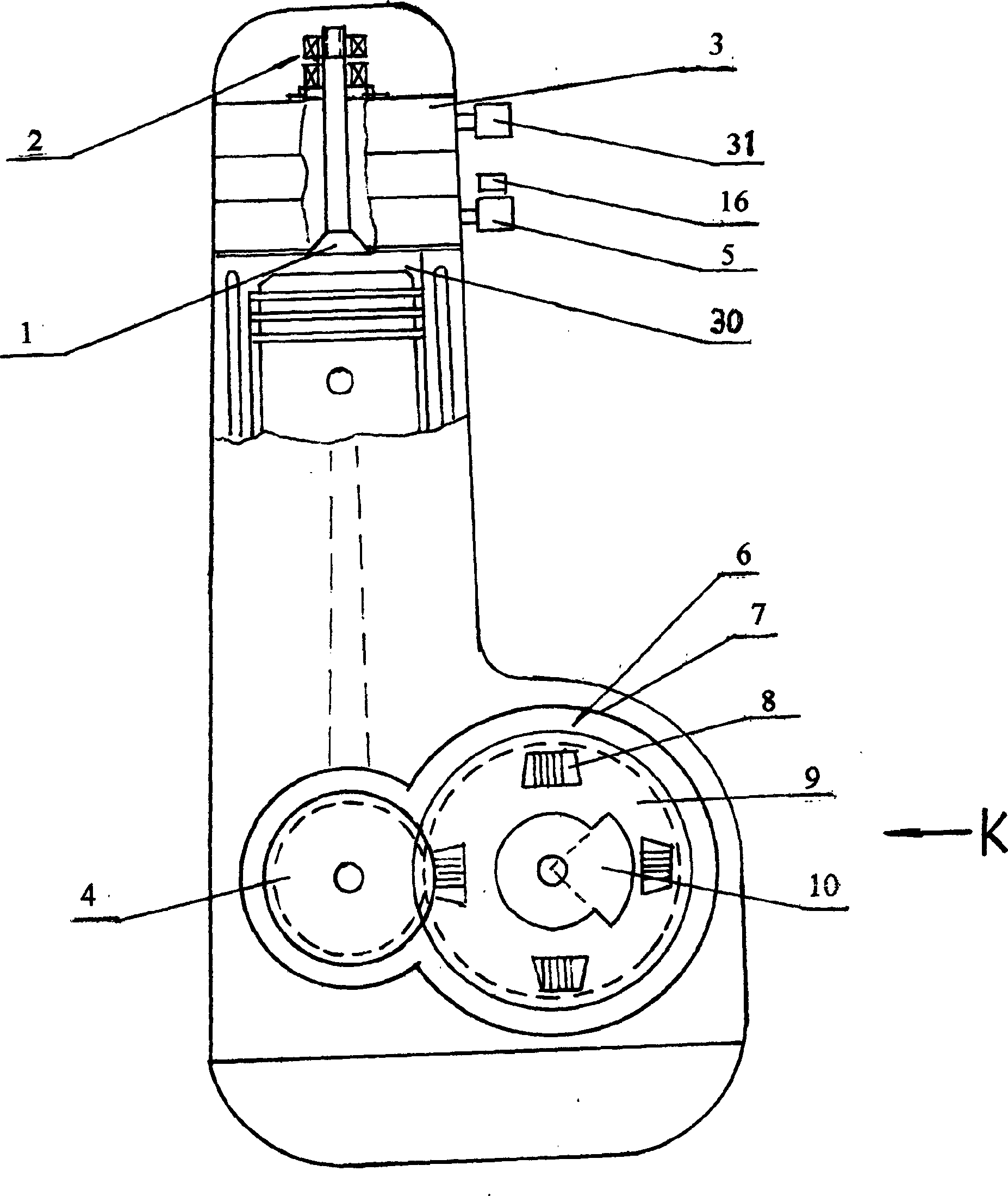

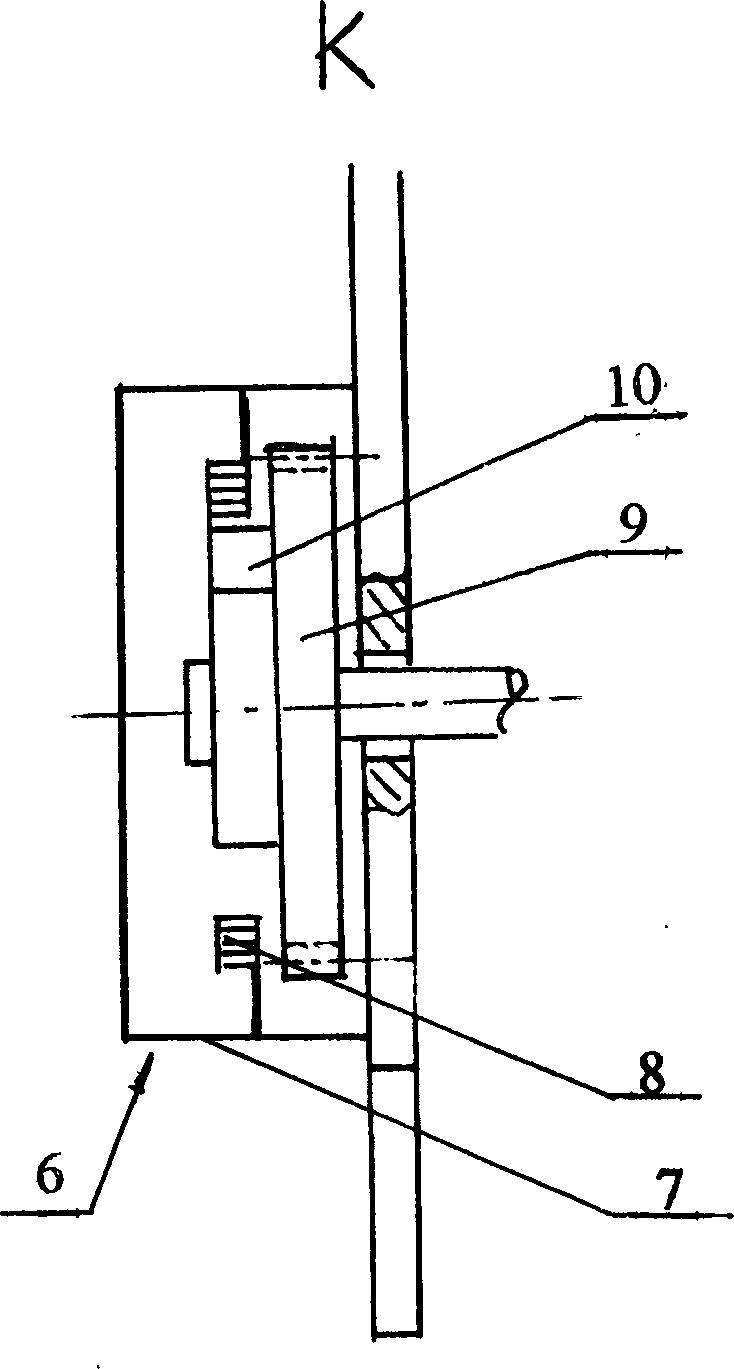

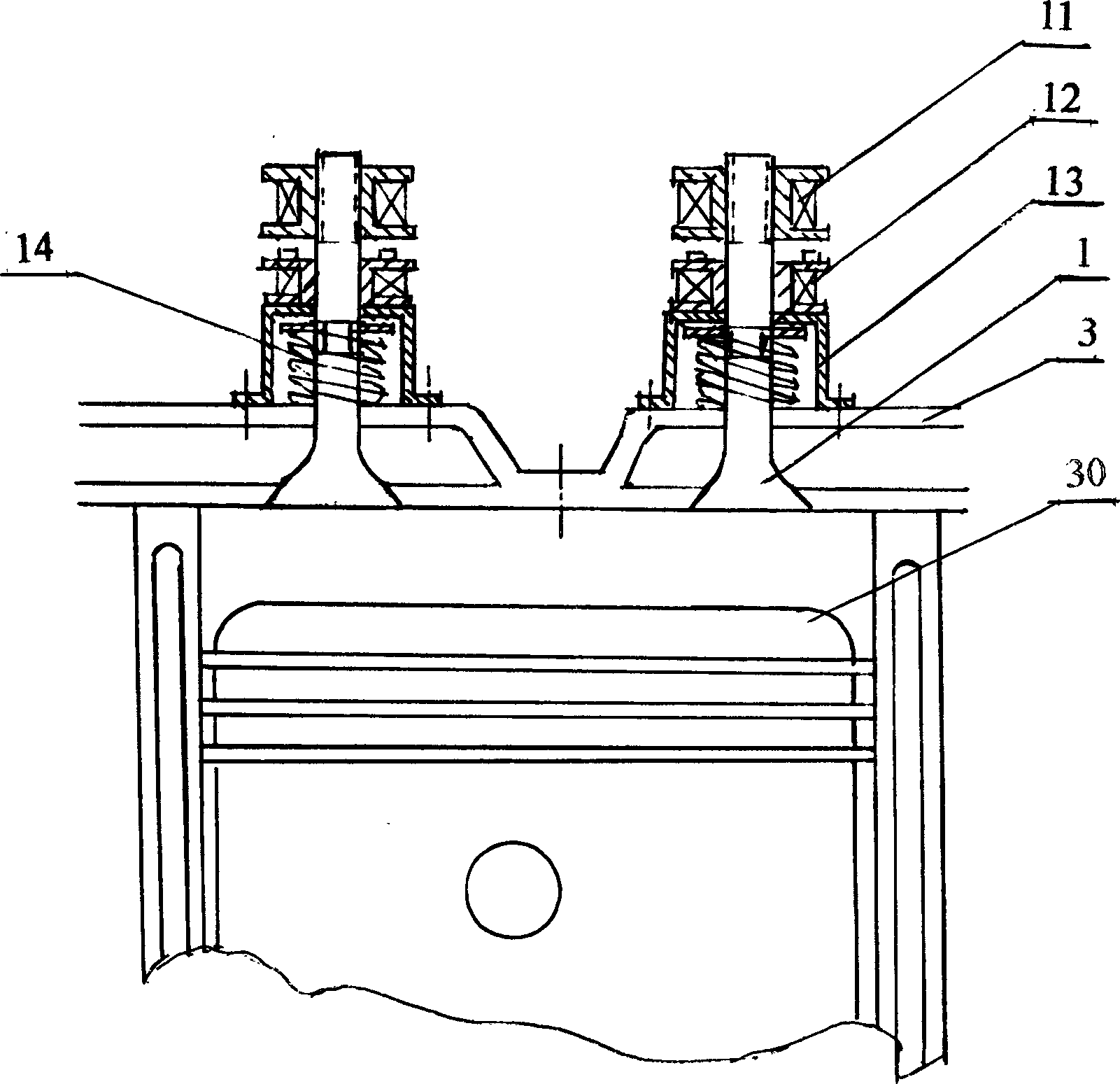

[0028] This example takes a four-cylinder engine as an example, an antiknock energy-saving engine, including a cylinder 30, a valve 1, a timing gear 9, a solenoid valve 2, a crank angle sensor 6, and a crank angle sensor 6 such as figure 2 , is composed of a timing rotor 10 and four crank angle pick-up coils 8 evenly distributed around the timing rotor 10 . The timing rotor 10 is provided with a raised part on the outer edge, the timing rotor 10 is fixedly connected to the timing gear 9 of the engine, the timing gear is engaged with the crankshaft drive gear 4, and the four crankshaft angle pickup coils 8 are fixed on On the timing gear cover 7. Its working principle: when the piston is close to the top dead center (before the intake stroke) or the bottom dead center (before the exhaust stroke), the convex part of the timing rotor 10 is closest to the crankshaft angle pick-up coil 8 of the cylinder. When the protruding part of the rotor 10 approaches, the magnetic flux in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com