Thermal interface material

A technology of thermal interface materials and metal particles, applied in heat exchange materials, electrical components, electrical solid devices, etc., can solve problems such as poor thermal conductivity and insufficient gap filling, to improve thermal conductivity, improve thermal conductivity, The effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

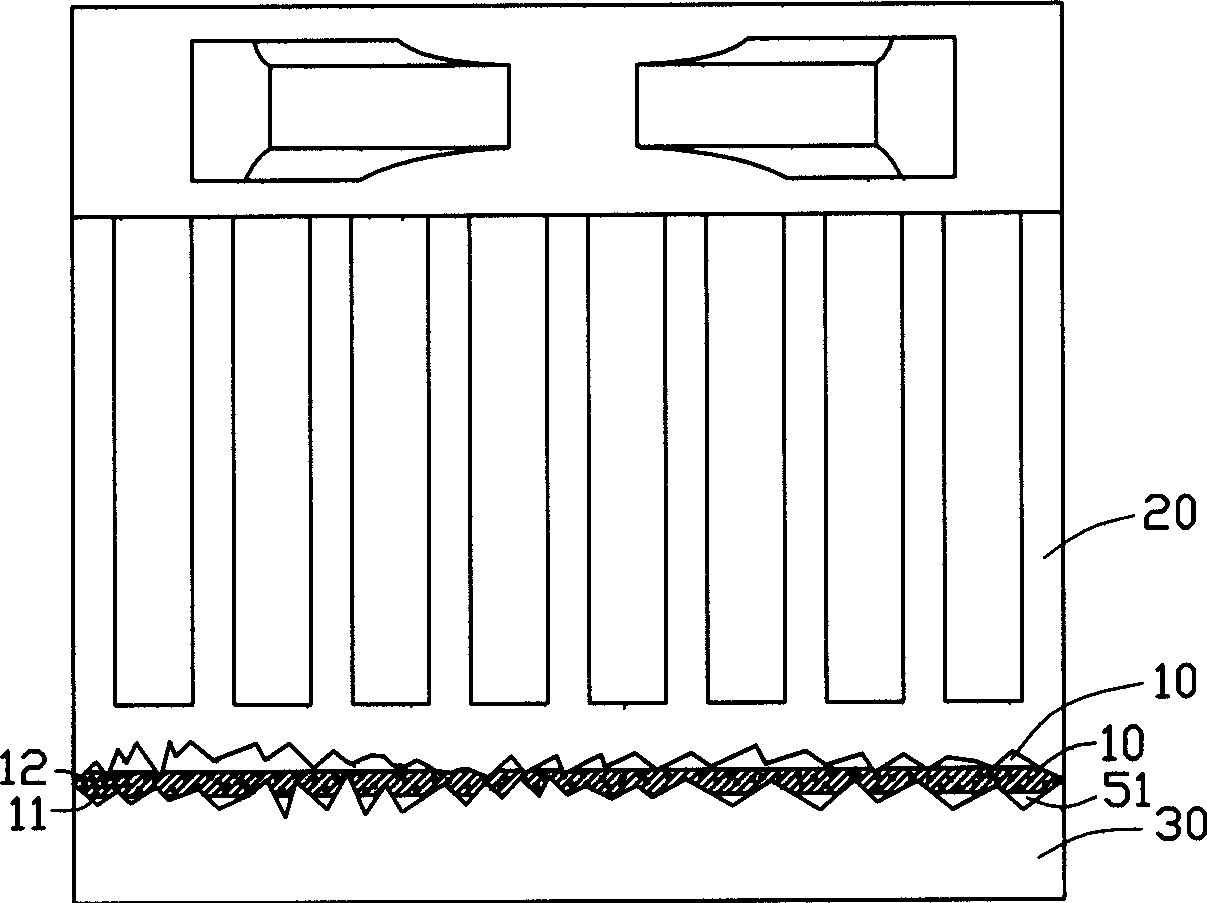

[0014] The present invention provides a thermal interface material, such as image 3 As shown, the thermal interface material 10 includes an interstitial fluid 11 and metal particles 12 distributed therein that can react with air. The metal particles 12 are nanoscale particles with a particle size of 1-100 nm, including one or more of Aluminum, Magnesium, Iron and other particles.

[0015] The interstitial fluid 11 includes oils, fats and gums, the oils include mineral oil, silicone oil, petroleum ointment and vaseline; the fats include animal fats and vegetable oils; the glues include silica gel (Silicone Glue) series, Polyethylene Glycol (Polyethylene Glycol), Epoxy Resin (Epoxy Resin) series, Oxygen-deficient adhesive series, Acrylic adhesive (Acrylic) series, etc.

[0016] The thermal interface material provided by the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com