Method for producing chitin, astaxanthin, protein, calcium powder and biological fertilizer from shrimp shell

A bio-fertilizer and astaxanthin technology, which is applied in the direction of animal carcass fertilizer, organic fertilizer, application, etc., can solve the problems of high product cost, pollution, environmental pollution, etc., and achieve the goal of reducing energy consumption, reducing environmental pollution, and improving extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

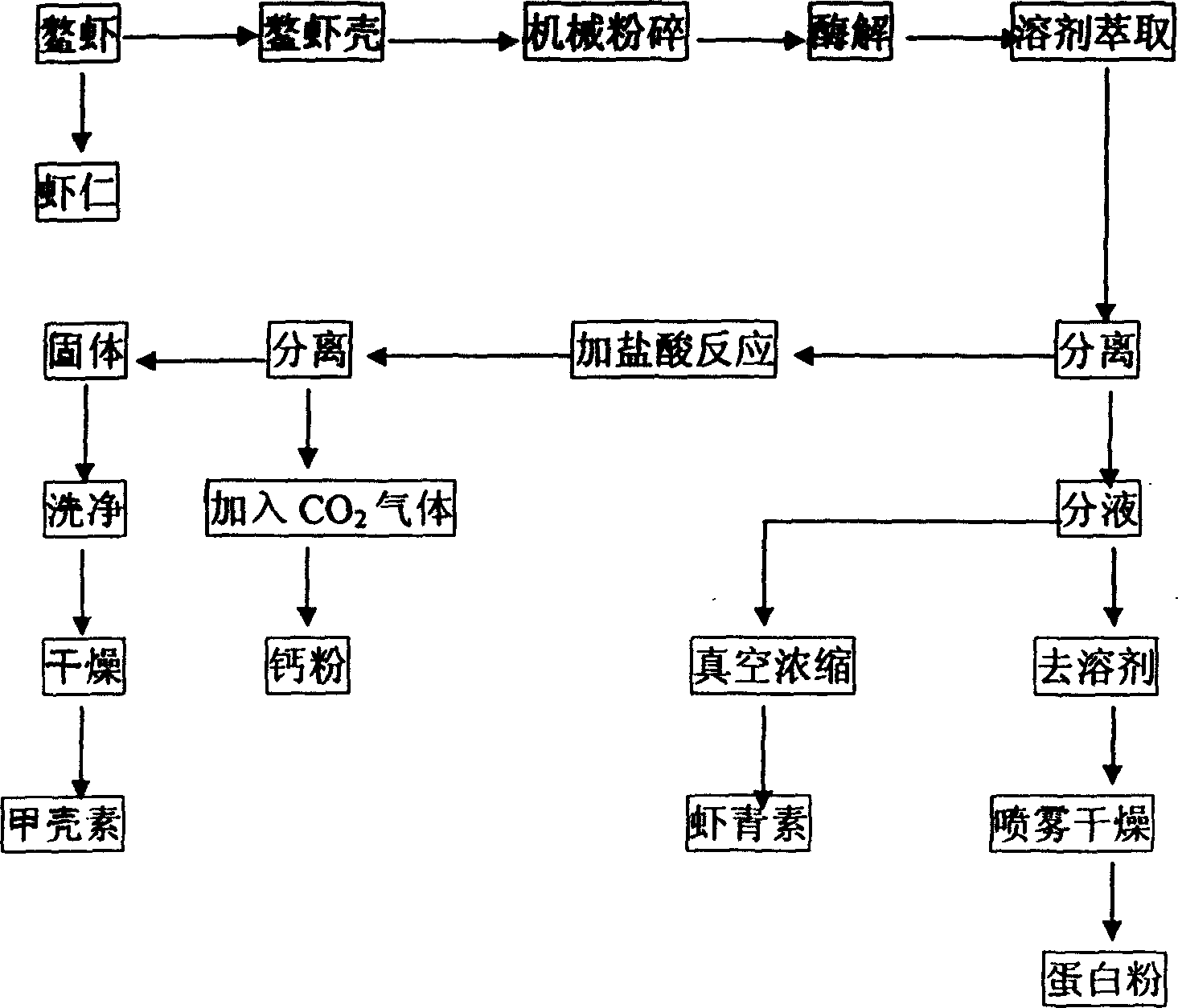

Image

Examples

Embodiment 1

[0022] 100 kg of crayfish shells washed to remove the dirt in the shrimp are mechanically crushed to 5-10 mesh. The purpose of crushing is to reduce energy consumption and improve yield, and pour it into the reaction kettle. Then add 100 kg of water into the reaction kettle for enzymolysis. The temperature of the enzymolysis is 30°C, the pH value is 4-8, and the time is 2 hours. Add 1 kg of protease. The main purpose of the enzymolysis is to separate the protein. After enzymatic hydrolysis, heat up to 80°C to sterilize the enzyme bacteria, and then cool down. Add 50 kg of petroleum ether, 20 kg of acetone and 80 kg of ethanol to the reaction kettle for extraction, fully airtight and stir for 6 hours and then cool. Then the liquid and the solid are separated, and the liquid is separated into a hydrolyzed liquid and an organic liquid, and the astaxanthin-containing organic liquid is vacuum-concentrated to extract the crude astaxanthin with a content of 0.5%. After liquid separa...

Embodiment 2

[0024] 200 kilograms of crayfish shells washed to remove the dirt in the shrimp are mechanically crushed to 5-10 mesh. The purpose of crushing is to reduce energy consumption and increase yield, and pour them into the reaction kettle. Then add 300 kg of water to the reaction kettle for enzymolysis. The temperature of the enzymolysis is 60°C, the pH value is 4-8, and the time is 5 hours. Add 1.6 kg of protease. The main purpose of the enzymolysis is to separate the protein. After enzymatic hydrolysis, heat up to 100°C to sterilize the enzyme bacteria, and then cool down. Then add 100 kg of petroleum ether and 300 kg of ethanol to the reaction kettle for extraction, fully airtight and stir for 10 hours and then cool. Then the liquid and the solid are separated, and the liquid is separated into a hydrolyzed liquid and an organic liquid, and the organic liquid containing astaxanthin is vacuum-concentrated to extract crude astaxanthin with a content of 1%. After liquid separation,...

Embodiment 3

[0026] 150 kg of crayfish shells washed to remove the dirt in the shrimp are mechanically crushed to 5-10 mesh. The purpose of crushing is to reduce energy consumption and improve yield, and pour it into the reaction kettle. Then add 300 kg of water to the reaction kettle for enzymolysis. The temperature of the enzymolysis is 70°C, the pH value is 4-8, and the time is 6 hours. Add 1.1 kg of protease. The main purpose of the enzymolysis is to separate the protein. After enzymatic hydrolysis, heat up to 70°C to sterilize the enzyme bacteria, and then cool down. Then add 50 kg of acetone and 100 kg of ethanol in the reaction kettle for extraction, fully airtight and stir for 8 hours and then cool. Then the liquid and the solid are separated, and the liquid is separated into a hydrolyzed liquid and an organic liquid, and the organic liquid containing astaxanthin is vacuum-concentrated to extract crude astaxanthin with a content of 0.7%. After liquid separation, the hydrolyzate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com