Short-pressure enhancing treatment of sweeping buffer spring

A technology for strengthening treatment and buffering springs, applied in the field of spring manufacturing, can solve problems such as inability to process springs, unable to produce qualified parts, etc., to achieve the effect of ensuring output characteristics, short production cycle, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take the production of a buffer spring as an example to describe the method in detail below:

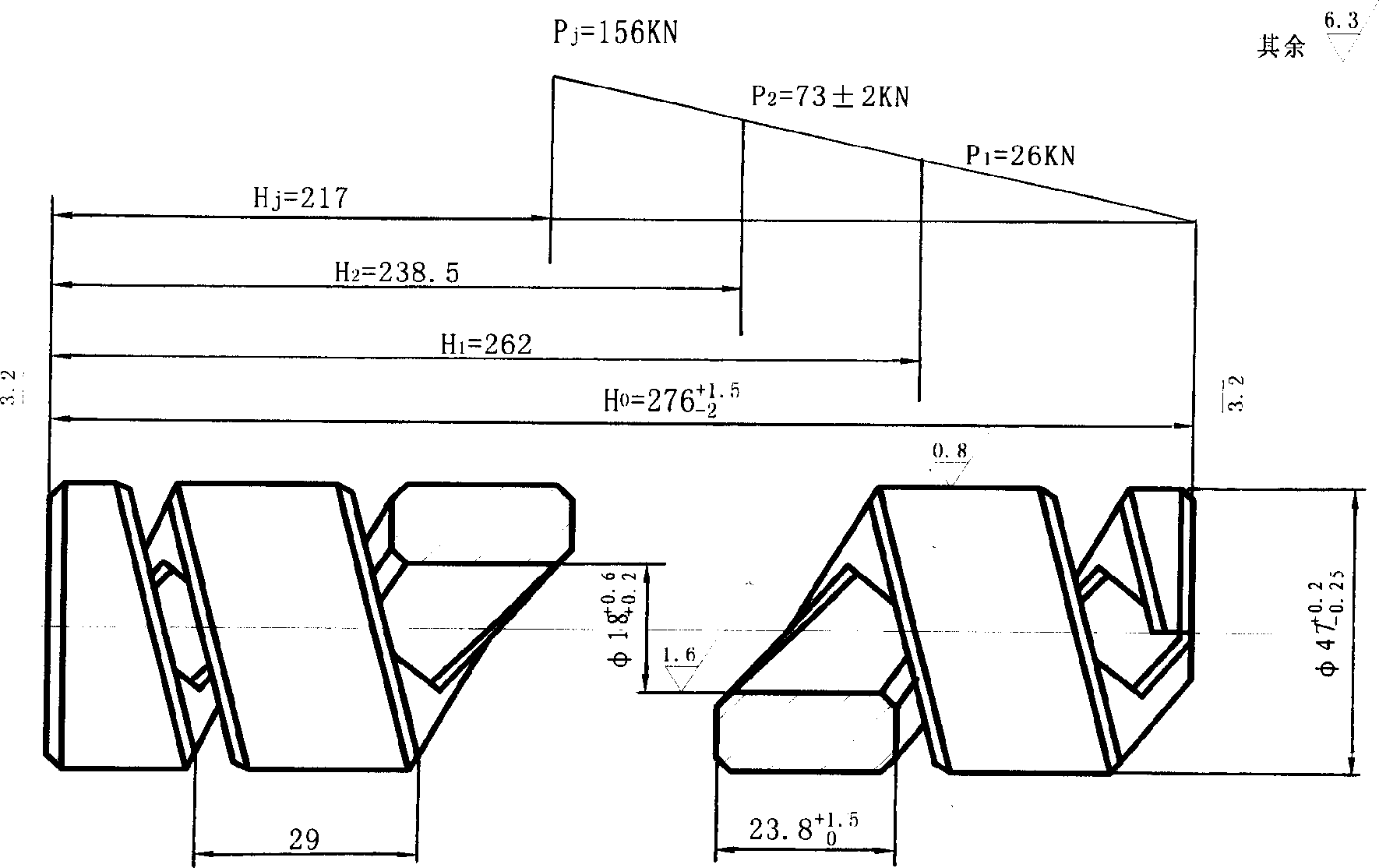

[0021] The structural parameters of the spring are shown in figure 1 , the pitch of the spring is 29mm, and the section thickness is 23.8 0 +1.5 mm, outer diameter 47 -0.25 +0.2 mm, inner diameter 18 -0.2 +0.6 mm, the finished product length H 0 for 276 -2 +1.5 mm, height H of working start state 1 262mm, pressure P 1 26KN, height H at the end of work 2 238.5mm, pressure P 2 73±2KN, spring pressure and height H j : 217mm; corresponding pressure P j 156KN

[0022] First, the first compression height of the spring should be calculated according to the prefabricated height HI of the spring, and the next compression amount of the spring should be determined according to each compression situation, and the compression amount and the corresponding pressure P′ and height H′ should be calculated, see Table 1 :

[0023] Table 1: List of buffer spring short pressure tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com