Apparatus and method for controlling ring laser optical cavity length

A ring laser and optical cavity technology, applied in the laser field, can solve the problems of high power consumption, long adjustment time, affecting the performance of the ring laser and the measurement accuracy of the laser gyro

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

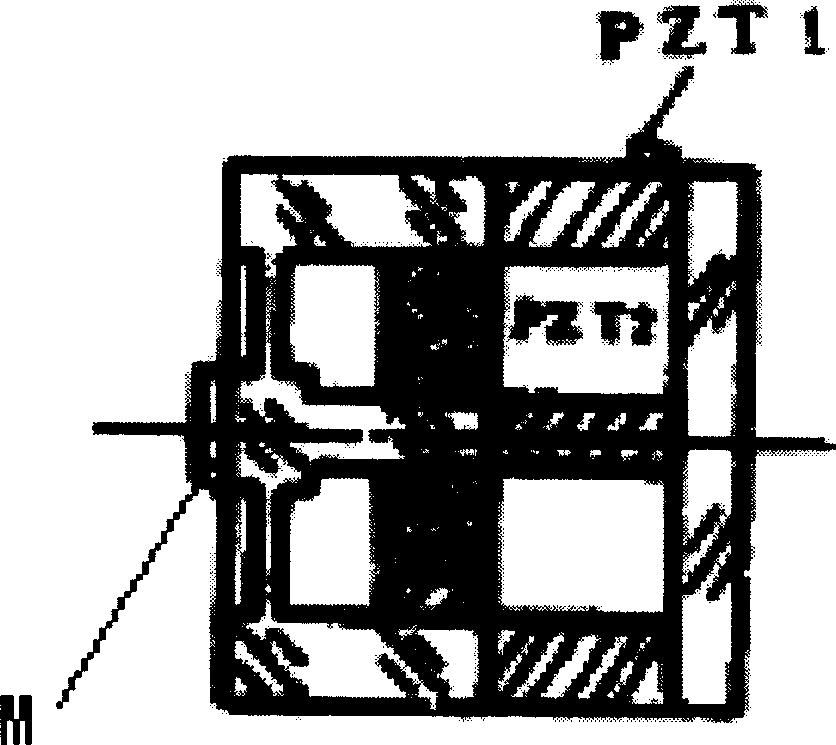

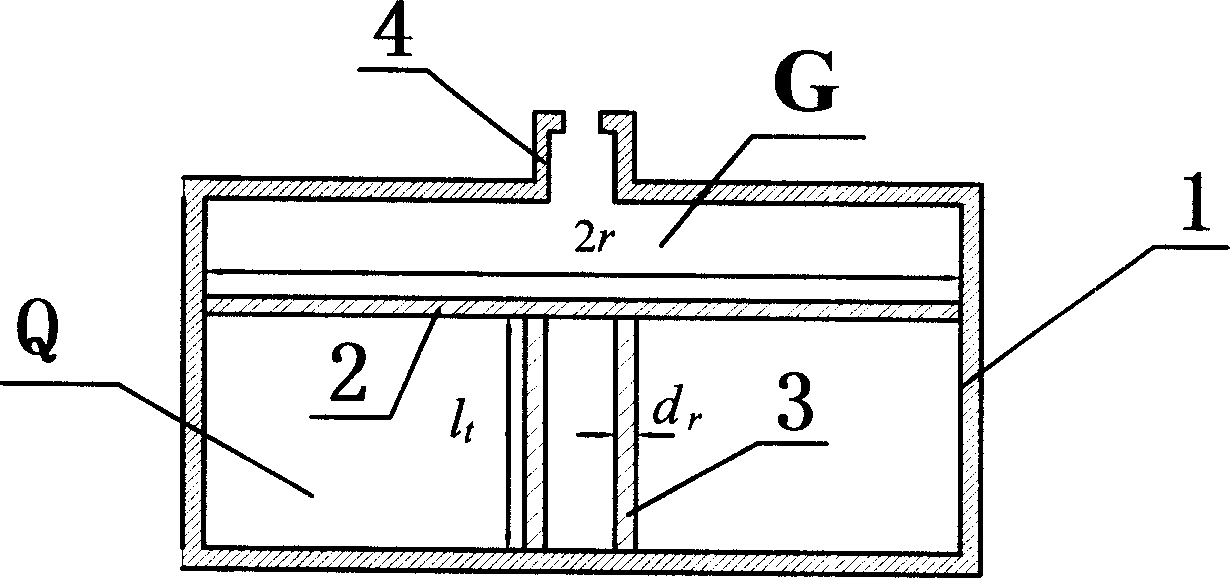

[0073] The device for controlling the optical cavity length of the ring laser proposed by the present invention can be used in the frequency stabilization system of the total reflection prism ring laser, such as Figure 4 shown. The nozzle 4 in the device for controlling the optical cavity length of the ring laser is connected to the capillary B in the total reflection prism ring laser through the heat insulating tube 5, 6 is the cavity of the ring laser, 7-10 are the total reflection prisms, 11-14 are The protective cover, A, B, C, D are the four capillaries of the ring laser. The capillary A of the ring laser is closed by total reflection prisms 9 and 10, and the gain gas is filled in the tube. The capillary B of the ring laser is closed by the protective cover 11 and 12, and the capillary B and the space G of the ring laser are filled with 1 standard Dry air at atmospheric pressure, vacuum in the capillaries C, D and space Q of the ring laser.

[0074] The present in...

Embodiment 2

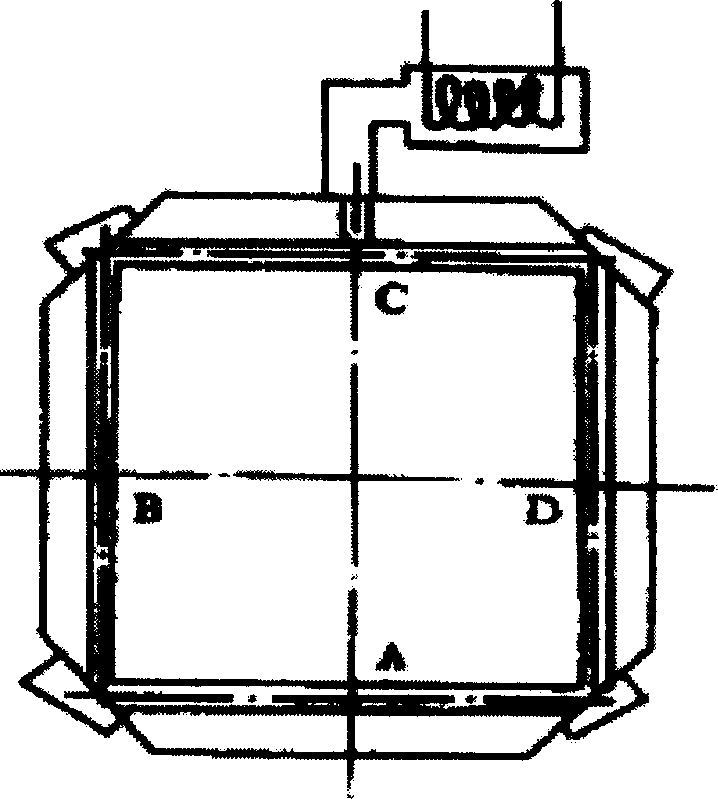

[0079] The control ring laser optical cavity length device of the present invention is used in the frequency stabilization system of mirror type ring laser, such as Figure 5 shown. The nozzle 4 in the device for controlling the optical cavity length of the ring laser is connected with the capillary B in the mirror ring laser through the heat insulating tube 5 . 6 is the cavity of the mirror-type ring laser, 15 and 16 are Brewster windows, and 17-20 are mirrors. The Brewster windows 15 and 16 separate the capillary of the ring laser into two parts, A and B, and at the same time, the Brewster windows 15 and 16 seal the capillary B of the ring laser. Capillary A of the ring laser is filled with gain medium gas, capillary B and space G of the ring laser are filled with dry air at 1 standard atmospheric pressure, and space Q is vacuum. The schematic diagram of the frequency stabilization system in this embodiment is also as Figure 6 shown.

[0080] When the ring laser i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com