Warming agent clathrate compound applied to absorbent products and preparation method for warming agent clathrate compound

A technology of absorbent products and clathrates, which is applied in the field of packs and objects, can solve the problems of high irritation and achieve the effect of lasting warmth and optimizing warmth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

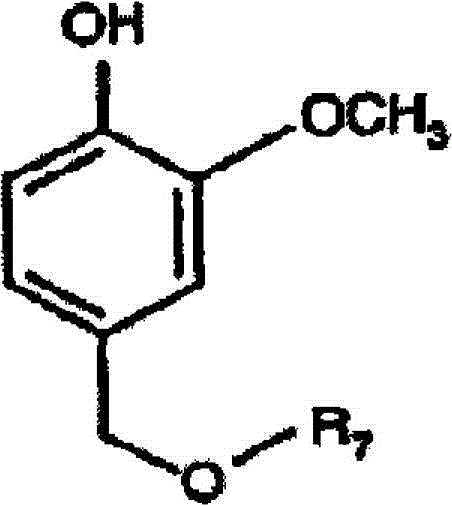

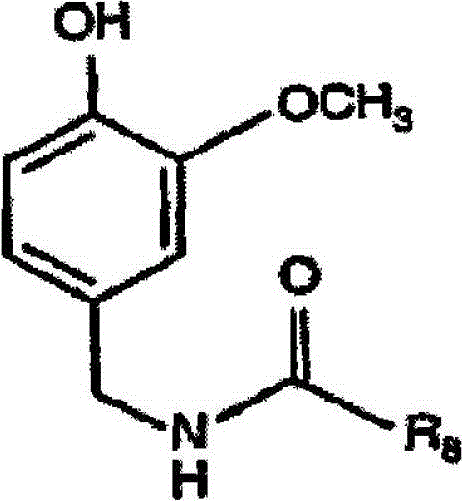

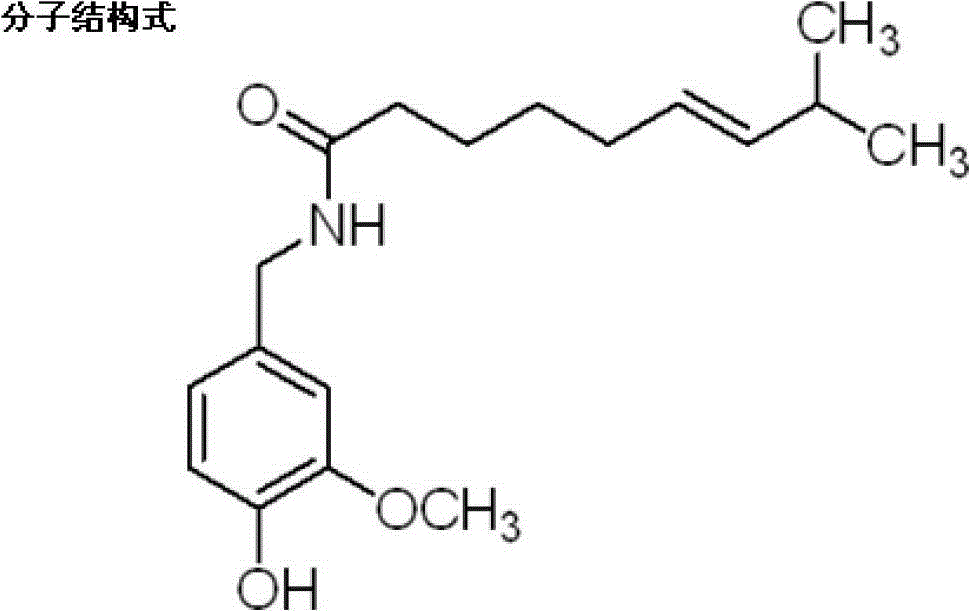

Image

Examples

Embodiment 1

[0063] To prepare clathrates, weigh 10g of β-cyclodextrin and place it in a reaction kettle, add 200ml of water and heat and stir until β-cyclodextrin is completely dissolved, and continue to heat up to 55°C to make a saturated aqueous solution; weigh 5g of ginger essential oil Dissolve with 5ml of propylene glycol, slowly add it into the reaction kettle with β-cyclodextrin under stirring condition, continue heating and stirring for 2h, concentrate the solution under reduced pressure to 50ml, refrigerate overnight at 4°C, filter out the precipitate, and place it at 90 After drying at ℃ for 1 hour, the cyclodextrin inclusion complex of ginger essential oil can be obtained, and the product is a white powder;

Embodiment 2

[0065] To prepare clathrates, weigh 15g of 2-hydroxypropyl-β-cyclodextrin and place it in a reaction kettle, add 200ml of water and heat and stir until 2-hydroxypropyl-β-cyclodextrin is completely dissolved, and continue to heat up to 70°C. Make a saturated aqueous solution; weigh 5g of vanillyl butyl ether and dissolve it in 5ml of ethanol, slowly add it into the reaction kettle containing 2-hydroxypropyl-β-cyclodextrin under stirring conditions, continue heating and stirring for 7h, while hot The precipitate was filtered out, and then dried at 90° C. for 1 hour to obtain the inclusion compound of vanillyl butyl ether cyclodextrin, which was a white powder.

Embodiment 3

[0067] To prepare clathrates, weigh 10g of β-cyclodextrin and place it in a reaction kettle, add 200ml of water and heat and stir until the β-cyclodextrin is completely dissolved, and continue to heat up to 75°C to make a saturated aqueous solution; weigh 2g of vanillin Dissolve -1,2-hexanediol acetal in 5ml PEG400, slowly add it into the reaction kettle containing β-cyclodextrin under stirring condition, continue heating and stirring for 1h, concentrate the solution under reduced pressure to 50ml, and refrigerate at 4°C Overnight, filter out the precipitate, and dry at 90°C for 1 hour to obtain the cyclodextrin inclusion compound of ginger essential oil, which is a white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com