Warming agent microcapsule for absorbent products and preparation method and application thereof

A microcapsule and absorbent technology, applied in the field of warming agent microcapsules for absorbent products and their preparation, can solve the problems of demulsification, inability to form, and decreased product entrapment rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A method for preparing warming agent microcapsules for absorbent products:

[0086] (1), Gum Arabic was dissolved in distilled water at 55°C, maltodextrin was added and dissolved, the mass ratio of gum Arabic to maltodextrin was 2:1, and a capsule material solution with a mass fraction of solute of 35% was made;

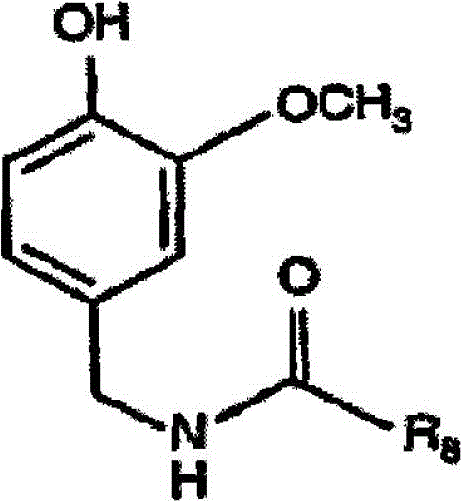

[0087] (2), vanillyl butyl ether, hydrogenated castor oil polyoxyethylene ether, and isopropyl myristate were stirred evenly at 55°C to obtain a core material solution; wherein 1.5 parts of vanillic butyl ether, hydrogenated castor oil polyoxyethylene 1.1 parts of ether, 7 parts of isopropyl myristate;

[0088] (3), add the core material solution prepared in (2) into the capsule material solution prepared in (1), the mass ratio of the core material to the wall material is 1:8, the temperature is 55°C, and the stirring speed is 1.55×10 4 Conditions, homogeneous emulsification 20min.

[0089] (4), spray drying control inlet air temperature 185 ℃, outlet air te...

Embodiment 2

[0091] A method for preparing warming agent microcapsules for absorbent products as described above,

[0092] (1), gum arabic is dissolved in distilled water at 40°C, maltodextrin is added and dissolved, the mass ratio of gum arabic to maltodextrin is 3:1, and a capsule material solution with a mass fraction of solute of 20% is made;

[0093] (2), vanillyl butyl ether, hydrogenated castor oil polyoxyethylene ether, and isopropyl myristate were stirred evenly at 40°C to obtain a core material solution; wherein 1 part of vanillic butyl ether, hydrogenated castor oil polyoxyethylene 0.1 parts of ether, 6 parts of isopropyl myristate;

[0094] (3), add the core material solution prepared in (2) into the capsule material solution prepared in (1), the mass ratio of the core material to the wall material is 1:6, the temperature is 40°C, and the stirring speed is 1.5×10 4 Under the condition of r / min, homogeneously emulsify for 10 minutes.

[0095] (4), spray drying control inlet ai...

Embodiment 3

[0097] A method for preparing warming agent microcapsules for absorbent products,

[0098] (1), Gum Arabic is dissolved in distilled water at 75°C, maltodextrin is added and dissolved, the mass ratio of gum Arabic to maltodextrin is 1:3, and a capsule material solution with a mass fraction of solute of 45% is made;

[0099](2), vanillyl butyl ether, hydrogenated castor oil polyoxyethylene ether, and isopropyl myristate were stirred evenly at 75°C to obtain a core material solution; wherein 2 parts of vanillic butyl ether, hydrogenated castor oil polyoxyethylene 2 parts ether, 9 parts isopropyl myristate;

[0100] (3), add the core material solution prepared in (2) into the capsule material solution prepared in (1), the mass ratio of the core material to the wall material is 1:10, the temperature is 75°C, and the stirring speed is 1.6×10 4 Under the condition of r / min, homogeneously emulsify for 30 minutes.

[0101] (4), spray drying control inlet air temperature 225 ℃, outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com