Oxidation exothemic reaction method and thermal energy generation body utilizing the same method

A technology of exothermic reaction and thermal energy, which is applied in the fields of heat generation by exothermic chemical reaction, heat generation by non-combustion exothermic chemical reaction, application, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

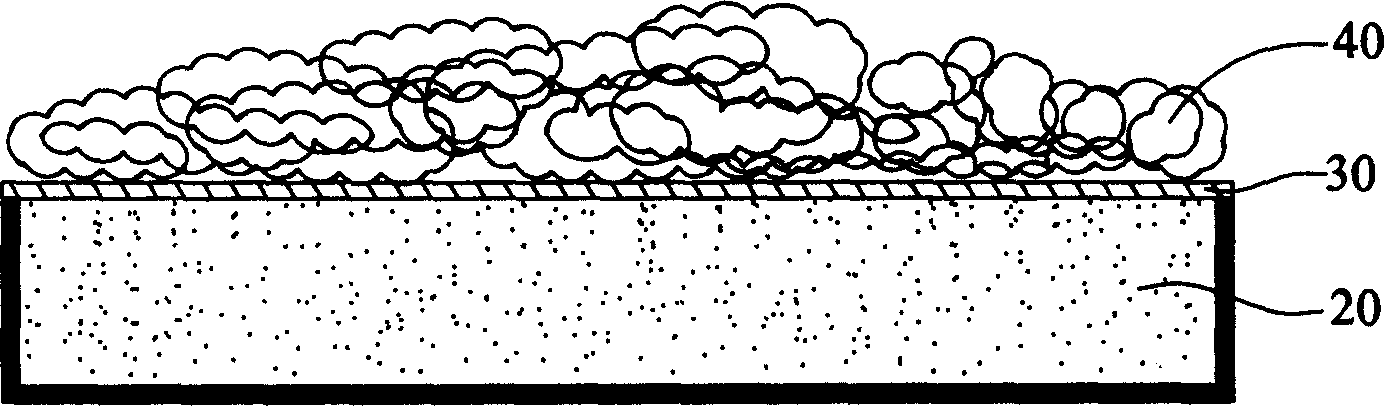

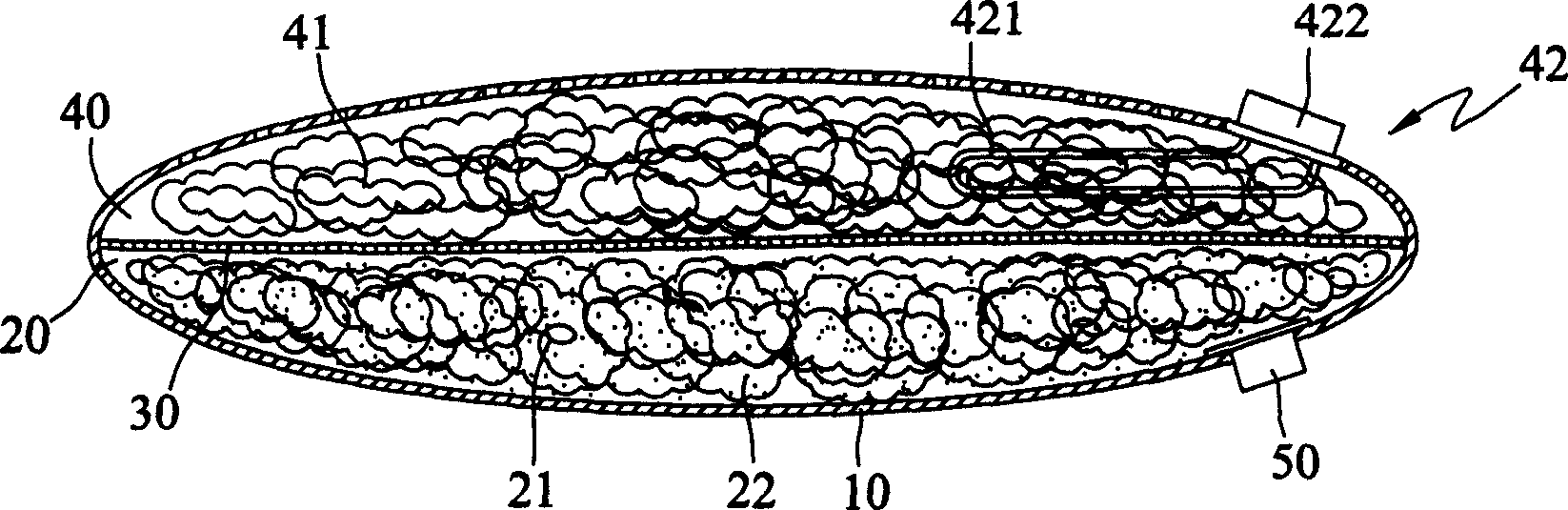

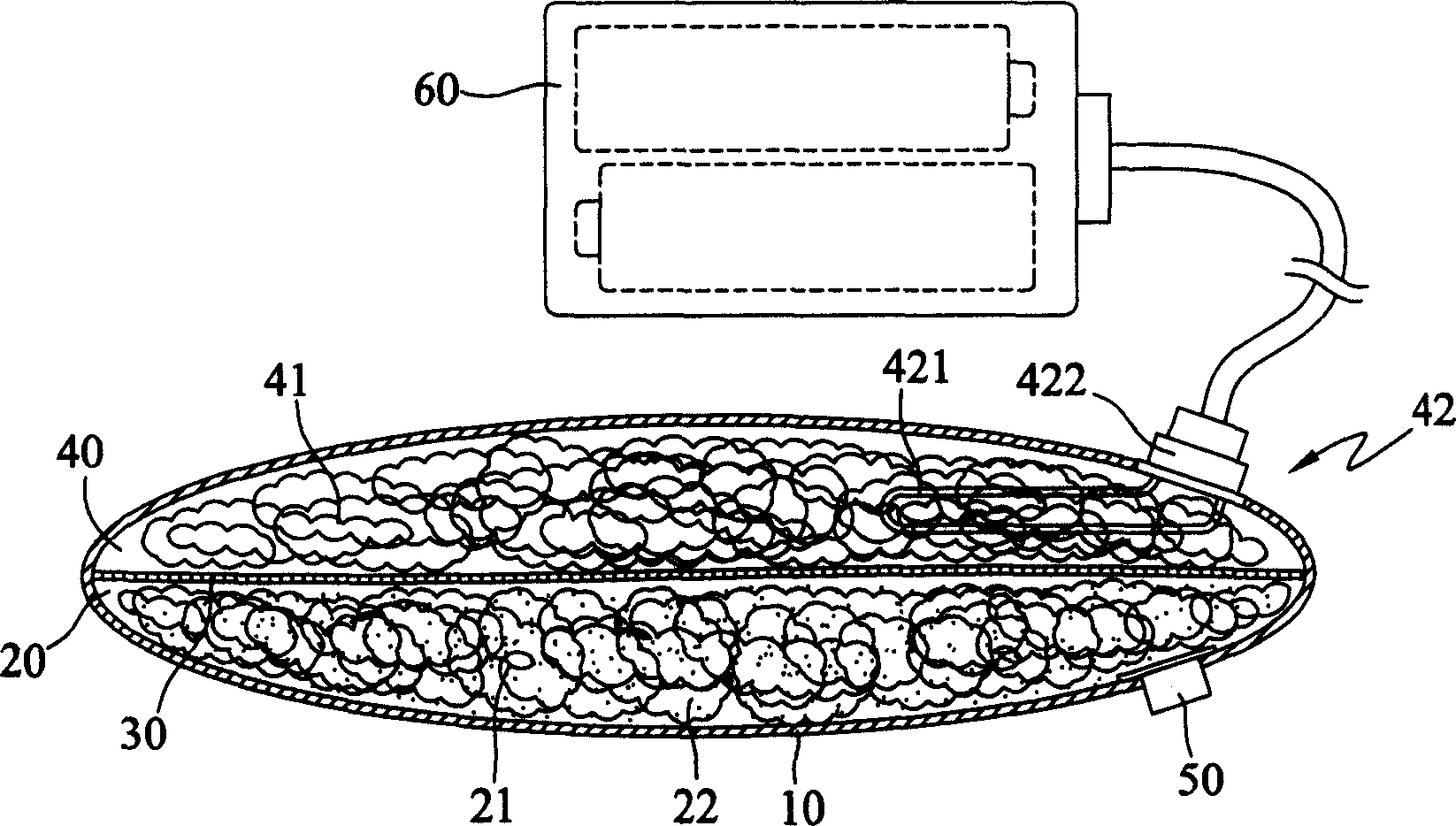

[0056] According to the oxidation exothermic reaction method disclosed in the present invention, chemical energy is converted into thermal energy. Such as figure 1 As shown, it completes the oxidation heat generation reaction through the fuel layer 20, the barrier layer 30 and the reaction layer 40, wherein the fuel layer 20 is such as alcohols (methanol, ethanol) or ethers or olefins or stain-removing oil or liquefied petroleum gas or Gas and other volatile liquid or gaseous fuels 22, the reaction layer 40 is a precious metal composite material 41 made of precious metal raw materials such as platinum, palladium, nickel, rhodium, iron, cerium, cobalt or their compounds, and the barrier layer 30 is made of glass fiber Cloth, glass fiber cotton, ceramic fiber cloth, ceramic fiber cotton and other materials are woven into denser fabrics, and polyethylene (Polyethylene, PE) or polyvinylchloride (Polyvinylchloride, PVC) or polyurethane Ester (Polyurethane, PU) and Teflon film, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com