Circuit device and manufacturing method thereof

一种电路装置、制造方法的技术,应用在电路装置、电路热装置、印刷电路制造等方向,能够解决难内置发热、装置整体散热性下降、印刷线路板散热性劣化等问题,达到容易搭载的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

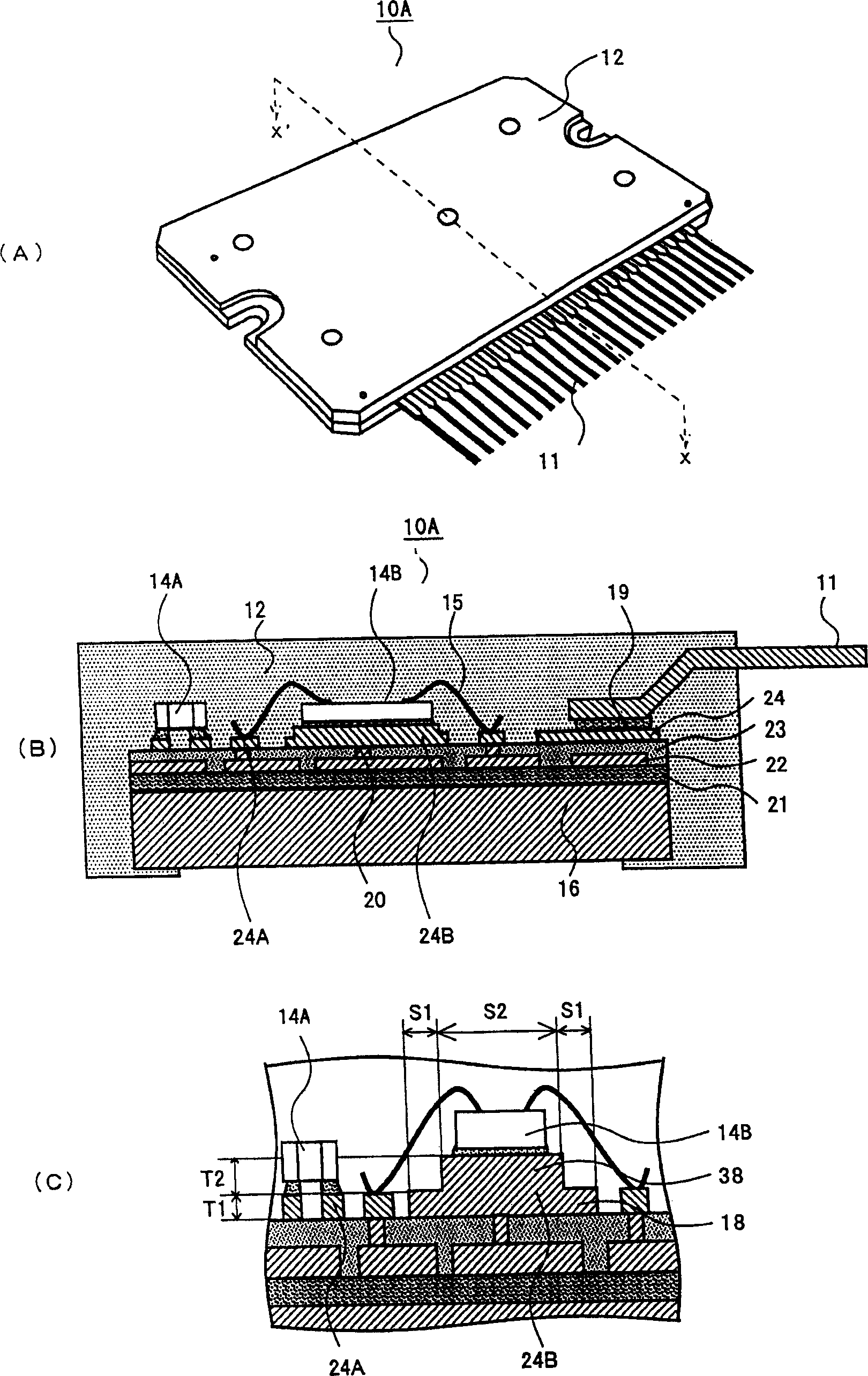

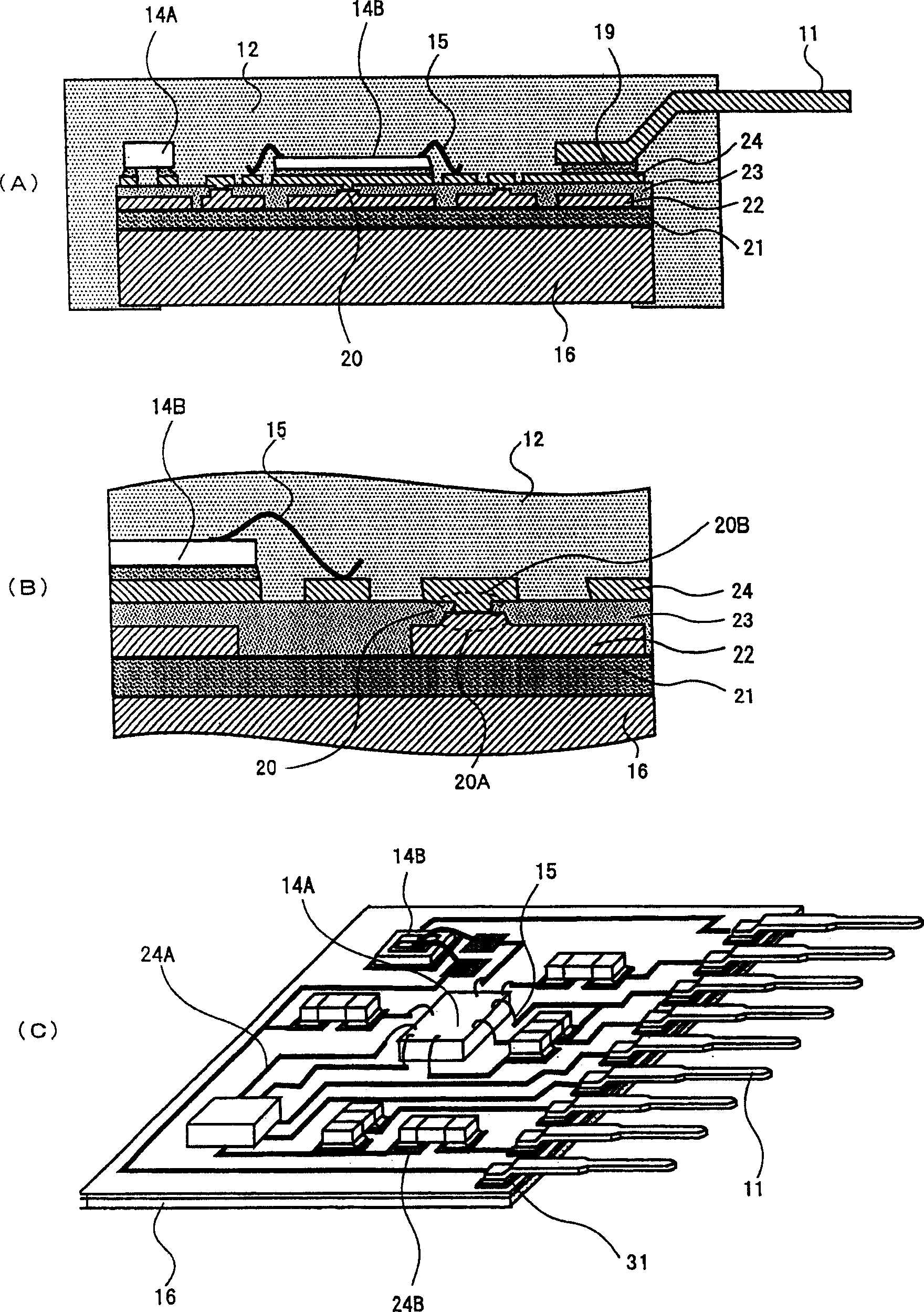

[0043] refer to figure 1 The configuration of the circuit device 10A of this embodiment will be described. figure 1 (A) is a perspective view of the circuit device 10A, figure 1 (B) is figure 1 (A) Cross-sectional view of X-X' section. figure 1 (C) is a cross-sectional view showing the portion of the second pattern 24B of this embodiment.

[0044] In this embodiment, the first insulating layer 21 is formed on the surface of the circuit board 16 made of aluminum, and the first wiring layer 22 is formed on the surface of the first insulating layer 21 . In addition, the second insulating layer 23 is formed on the surface of the first wiring layer 22, and the second wiring layer 24 is formed on the surface of the second insulating layer 23 to constitute a multilayer structure. In addition, the second wiring layer 24 is composed of a first conductive pattern 24A and a second conductive pattern 24B formed thicker than the first conductive pattern 24A. Furthermore, the back...

no. 2 example

[0121] refer to Figure 13 The circuit device 40 of this embodiment will be described. Figure 13 Each of the drawings is a cross-sectional view of the circuit device of this embodiment.

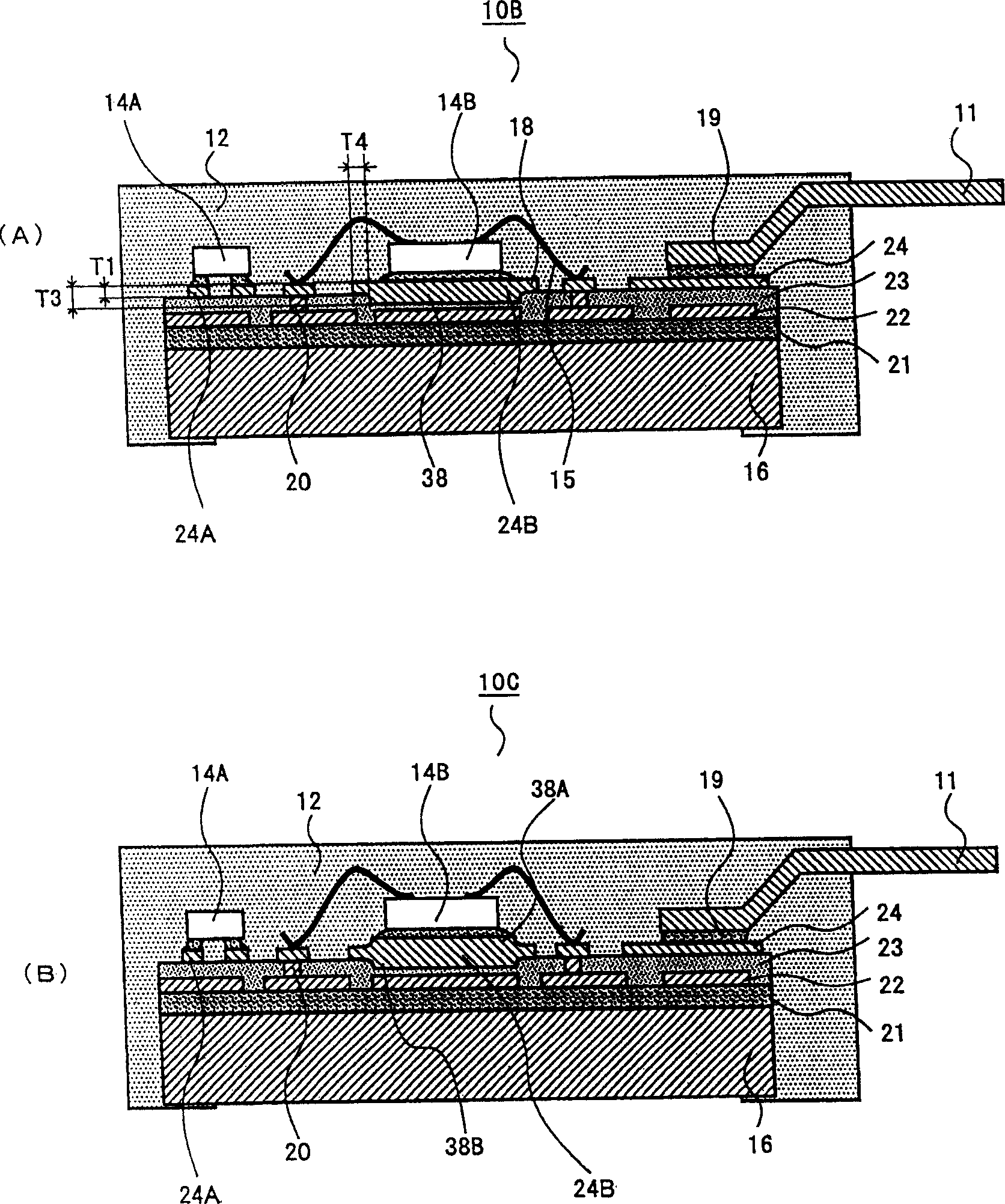

[0122] refer to Figure 13 (A), a multilayer wiring structure composed of two wiring layers is formed on the circuit device 40A. The upper first wiring layer 41 is composed of a first conductive pattern 41A and a second conductive pattern 41B formed thicker than the first conductive pattern 41A. Furthermore, the back surfaces of the first conductive pattern 41A and the second conductive pattern 41B are arranged substantially at the same level, and the convex portion 38 is formed so that the surface of the second conductive pattern 41B is located above the surface of the first conductive pattern 41A. First, let the thickness of the first conductive pattern 41A be T1, and let the thickness of the second conductive pattern 41B be T3. In order to finely form the first conductive pattern 41A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com