Light sensitive resin composition

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of unevenness, uneven coating of interlayer insulating film, poor flatness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

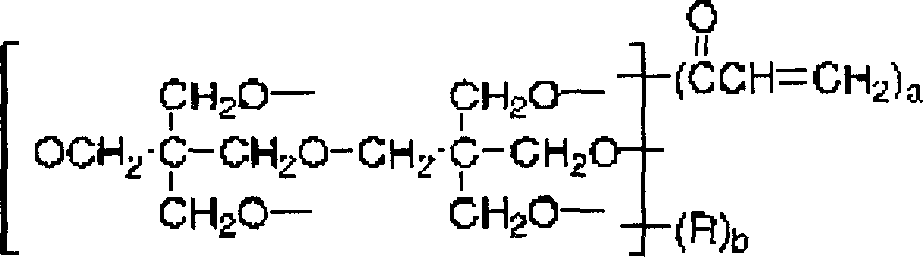

Image

Examples

Embodiment 1

[0073] (manufacture of acrylic copolymer)

[0074] In a flask with a cooling tube and a stirrer, add 10 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile), 500 parts by weight of tetrahydrofuran, 20 parts by weight of methacrylic acid, 25 parts by weight Glycidyl methacrylate, 40 parts by weight of styrene, 5 parts by weight of 2-hydroxyethyl acrylate, and 10 parts by weight of isobornyl acrylate were replaced with nitrogen and slowly stirred. The reaction solution was heated to 62° C. and maintained at this temperature for 5 hours to produce a polymer solution containing an acrylic copolymer.

[0075] In order to remove unreacted monomers in the polymer solution, 100 parts by weight of the polymer solution were precipitated with respect to 100 parts by weight of a poor solvent formed by mixing ether and n-hexane at a ratio of 1:1. . Subsequently, the poor solvent in which the unreacted substance was dissolved was removed by a filtration step using a mesh. Then, vacu...

Embodiment 2

[0081] Except having used hexanol instead of the benzyl alcohol which is a solvent in the said Example 1, it implemented by the method similar to the said Example 1, and manufactured the photosensitive resin composition.

Embodiment 3

[0083] Except having used diethylene glycol methyl ethyl ether instead of the benzyl alcohol which is a solvent in the said Example 1, it carried out by the method similar to the said Example 1, and manufactured the photosensitive resin composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com