3D (three-dimensional) printing light-cured resin and preparation method thereof

A light-curing resin and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of low molding efficiency and fast curing, and achieve the effects of fast molding speed, improved processing efficiency, and high light sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

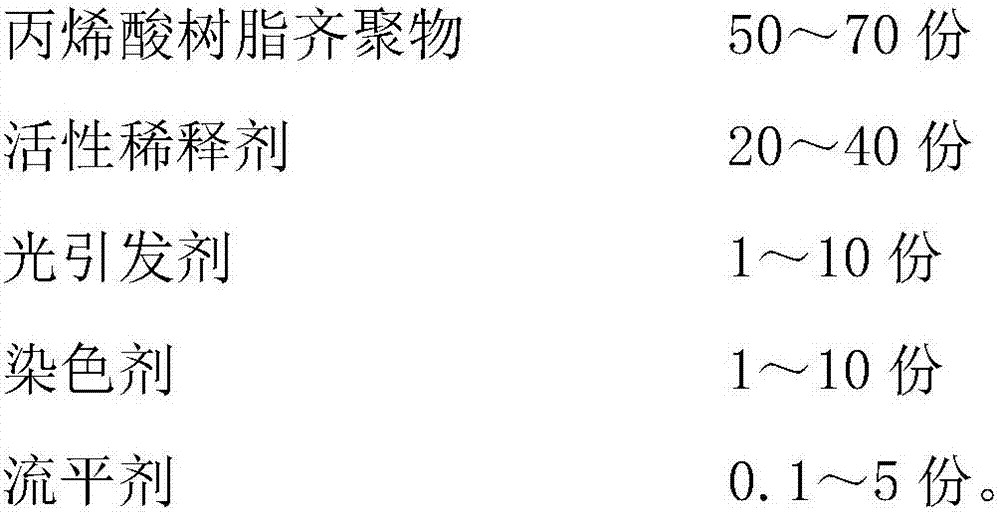

Method used

Image

Examples

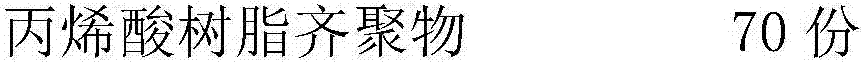

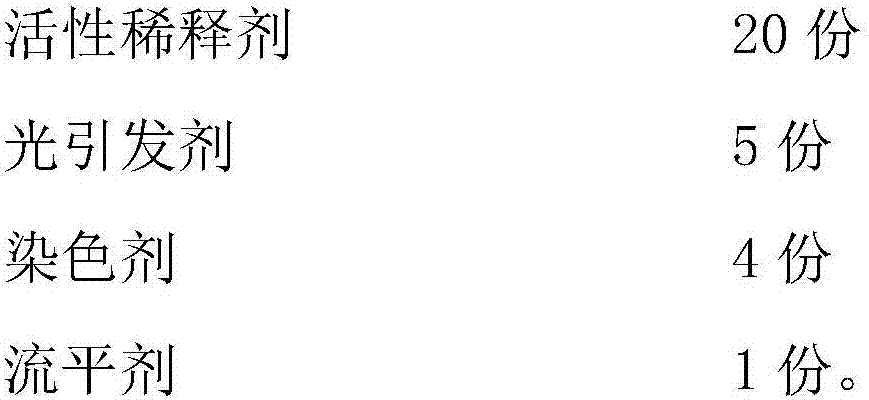

Embodiment 1

[0051] In parts by weight, add 1 part of benzoin dimethyl ether as a photoinitiator to 20 parts of 1,6-hexanediol diacrylate, and then ultrasonically vibrate evenly in a water bath at 40 ° C to dissolve the photoinitiator until transparent , to obtain an intermediate mixture; then add 20 parts of hyperbranched polyester acrylate, 15 parts of aliphatic urethane acrylate, and 15 parts of aromatic urethane acrylate into the intermediate mixture in turn, adding 1 part of peacock Stone green is used as a dyeing agent, 0.1 part of BYK-056 from BYK is added as a leveling agent, and 0.1 part of phenyl o-hydroxybenzoate is added as an ultraviolet light absorber. Finally, after 10 minutes of ultrasonic vibration, the 3D printing photocurable resin is prepared. .

[0052] The 3D printing light-curing resin prepared in this example was printed by a molecular sieve ultra-fast 3D printing equipment, and it was found that the curing time of a single layer of the resin was within 0.5s, and a ...

Embodiment 2

[0054] In parts by weight, 10 parts of 2-phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone was added to 40 parts of trimethylolpropane triacrylate as photoinitiator in a water bath at 60°C, and ultrasonically vibrate evenly to dissolve the photoinitiator until transparent to obtain an intermediate mixture; then add 35 parts of hyperbranched polyester acrylate, 15 parts of aliphatic urethane acrylate, 20 parts of Acrylic resin oligomer composed of a mixture of aromatic urethane acrylates, adding 10 parts of eosin Y as a dyeing agent, adding 5 parts of BYK-501A from BYK as a leveling agent, adding 5 parts of 2-hydroxy-4- Methoxybenzophenone is the ultraviolet light absorber, and after 30 minutes of ultrasonic vibration, the 3D printing photocurable resin is prepared.

[0055] The 3D printing light-curing resin prepared in this example was printed through a molecular sieve ultra-fast 3D printing device, and it was found that the curing time of a single layer of r...

Embodiment 3

[0057] In parts by weight, 2 parts of benzoin dimethyl ether and 1 part of 1-hydroxycyclohexyl phenyl ketone were added as photoinitiators to 7.5 parts of 1,6-hexanediol diacrylate, 7.5 parts of trimethylolpropane Triacrylate, 15 parts of polydipentaerythritol hexaacrylate; then ultrasonically vibrated in a water bath at 50°C to dissolve the photoinitiator until transparent to obtain an intermediate mixture; then add 30 parts of hyperbranched polyester to the intermediate mixture in sequence Acrylic resin oligomer composed of a mixture of acrylate, 15 parts of aliphatic urethane acrylate and 15 parts of aromatic urethane acrylate, adding 6 parts of malachite green as a dyeing agent, adding 3 parts of BYK-056 from BYK as a fluid As a leveling agent, add 2 parts of phenyl o-hydroxybenzoate as a UV light absorber, and finally oscillate with ultrasonic waves for 15 minutes to prepare a 3D printing photocurable resin.

[0058] The 3D printing light-curing resin prepared in this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com