Aluminium base composite material ultra sonic electrical resistance welding method

An aluminum-based composite material and resistance welding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of long welding cycle, difficult brazing process, and low joint strength, and achieve short welding time and wide range of soldering materials. Wide and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific embodiment one: this embodiment is carried out according to the following steps: a, before welding, polish the surface of the aluminum-based composite material to be welded with sandpaper, and carry out ultrasonic cleaning in acetone; b, after the test piece is dried, put the solder on Between the surfaces of the aluminum-based composite material to be welded, heat the specimen to a welding temperature of 400-600°C, and keep it warm for 0-60 seconds; c, stop heating, reduce the thickness of the liquid phase film between the two specimens, and control the thickness of the liquid phase film 30-300μm; d. Apply ultrasonic vibration, wherein the frequency of ultrasonic vibration is 15-60K Hz, the amplitude is 5-50μm, and the introduction time of ultrasonic is 0.1-30s; e. After the ultrasonic vibration is over, apply 0.1-20MPa welding to the test piece pressure, and then allowed the specimen to cool naturally. The aluminum matrix composites used can be C fiber reinfo...

specific Embodiment approach 2

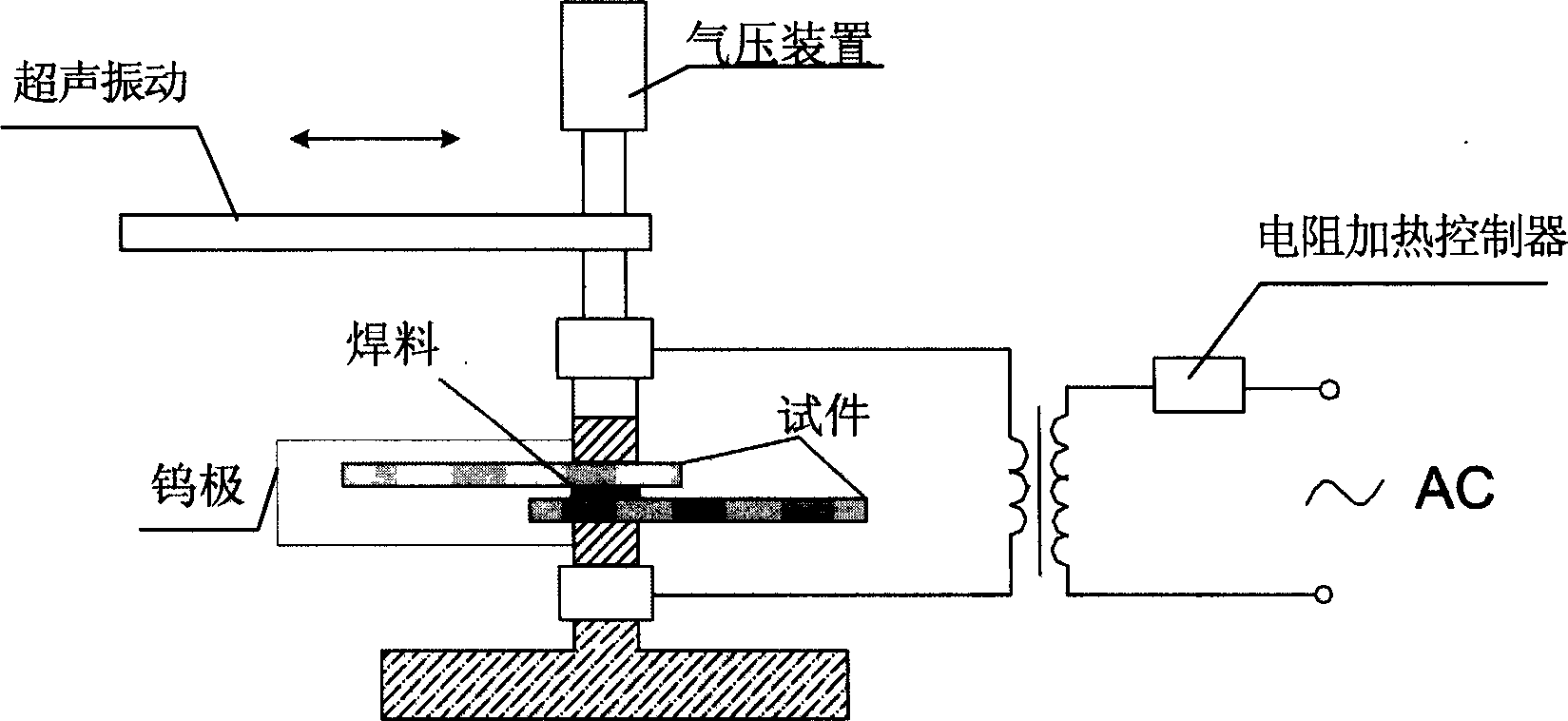

[0035] Specific implementation mode two: see figure 1 , the cylindrical pressure rod of the air pressure device passes through the ultrasonic vibration output rod and is closely connected with it; the lower end of the pressure rod of the air pressure device is made of tungsten material, which is in direct contact with the upper test piece, and the uppermost end of the base is also made of tungsten The pole is in direct contact with the lower test piece; the pressure rod and the terminal lead out from the base, so that the current passes through the tungsten poles at both ends. Present embodiment is realized like this: use 400 before a, welding # Grind the surface of the aluminum-based composite material to be welded with sandpaper, and perform ultrasonic cleaning in acetone; b. After the specimen is dried, place a thin sheet of solder between the surfaces of the aluminum-based composite material to be welded, and start the resistance heating device to test The parts are heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com