Method for producing aluminium under low-temperature and apparatus thereof

A low-temperature, aluminum electrolytic cell technology, which is applied in the field of low-temperature production of aluminum, can solve the problems of the electrolytic cell not working normally, the reduction of the heat generated by the electrolyte resistance, etc., and achieve the effects of low cost, high current efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

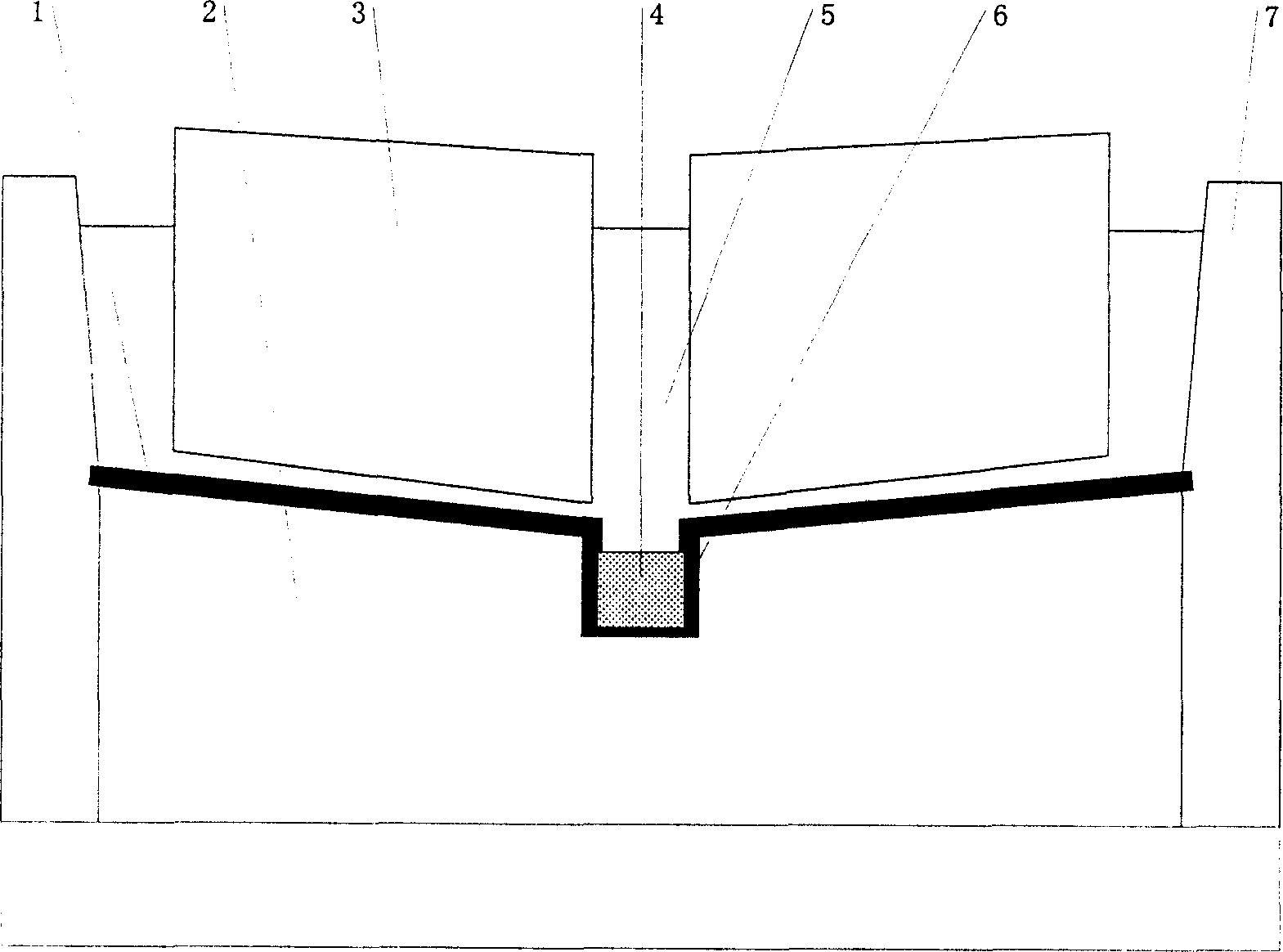

Embodiment 1

[0010] Example 1, the current intensity of the aluminum electrolytic cell is 160kA, and the material used for the cathode coating is TiB 2 , C powder and MoSi 2 Composite material, MoSi 2 The weight percentage content is 2%, the C powder weight percentage content is 35%, TiB 2 The weight percent content is 63%, and it is made by vibration molding method, and the cathode gradient is 10°. The anode is a prebaked carbon anode, the slope at the bottom is parallel to the opposite cathode, and the slope is the same, and the pole distance of the electrolytic cell is 2.5cm. Both the electrolytic tank side wall material and the aluminum sink material use silicon nitride combined with silicon carbide material. The electrolyte used in the electrolysis is a sodium cryolite molten salt system, wherein the content of sodium cryolite is 85% by weight, the content of aluminum fluoride is 12% by weight, and the content of lithium fluoride is 3% by weight. The electrolyte is formed by using...

Embodiment 2

[0011] Embodiment 2, the current intensity of the aluminum electrolytic cell is 280kA, and the material used for the cathode coating is TiB 2 , C powder and MoSi 2 Composite material, MoSi 2 The weight percentage content is 3%, the C powder weight percentage content is 40%, TiB 2 The weight percent content is 57%, and it is made by vibration molding method, and the cathode slope is 15°. The material used for the anode is a common industrial prebaked anode, the slope at the bottom is parallel to the opposite cathode, the slope is the same, and the pole distance of the electrolytic cell is 2cm. Both the side wall material and the aluminum sink material use silicon nitride combined with silicon carbide material. The electrolyte used in the electrolysis is a sodium cryolite molten salt system, wherein the weight percentage of sodium cryolite is 70%, the weight percentage of aluminum fluoride is 25%, and the weight percentage of lithium fluoride is 5%. An electrolyte composed o...

Embodiment 3

[0012] Embodiment three, the current intensity of the aluminum electrolytic cell is 320kA, and the material used for the cathode coating is TiB 2 , C powder and MoSi 2 Composite material, MoSi 2 The weight percentage content is 5%, the C powder weight percentage content is 50%, TiB 2 The weight percent content is 45%, and it is made by vibration molding method, and the cathode gradient is 20°. The material used for the anode is a common industrial prebaked anode, the slope at the bottom is parallel to the opposite cathode, the slope is the same, and the pole distance of the electrolytic cell is 2.5cm. Both the side wall material and the aluminum sink material use silicon nitride combined with silicon carbide material. The electrolyte used in the electrolysis is a sodium cryolite molten salt system, wherein the content of sodium cryolite is 80% by weight, the content of aluminum fluoride is 15% by weight, and the content of lithium fluoride is 5% by weight. An electrolyte c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com